Dr Rajiv Desai

An Educational Blog

Electric Vehicle, EV (electric car)

Electric Vehicle, EV (electric car):

_

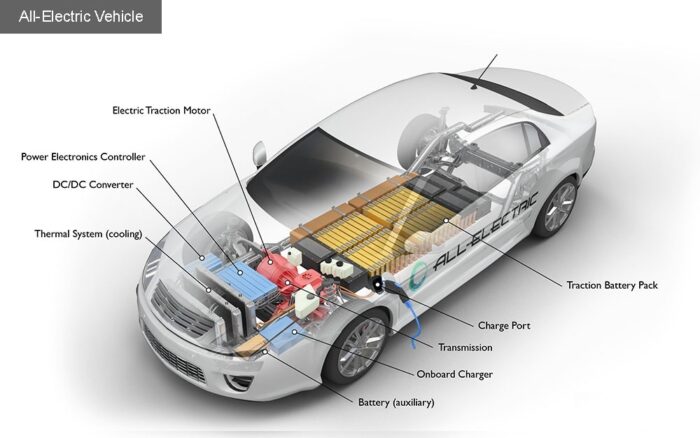

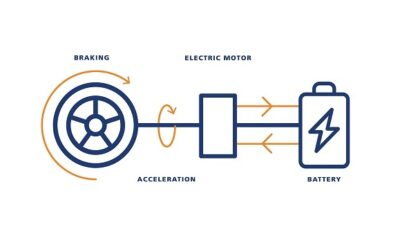

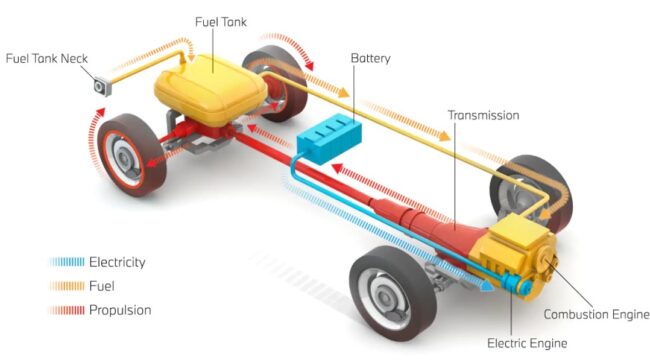

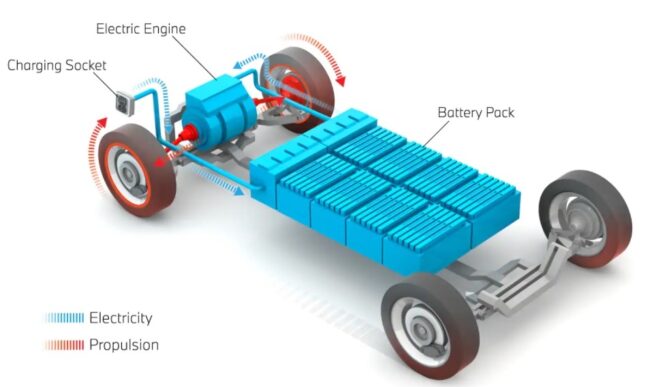

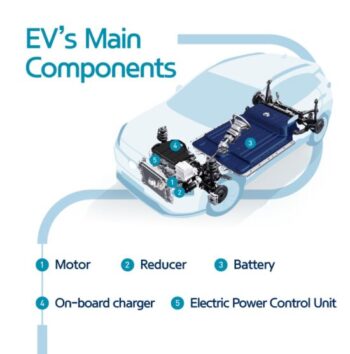

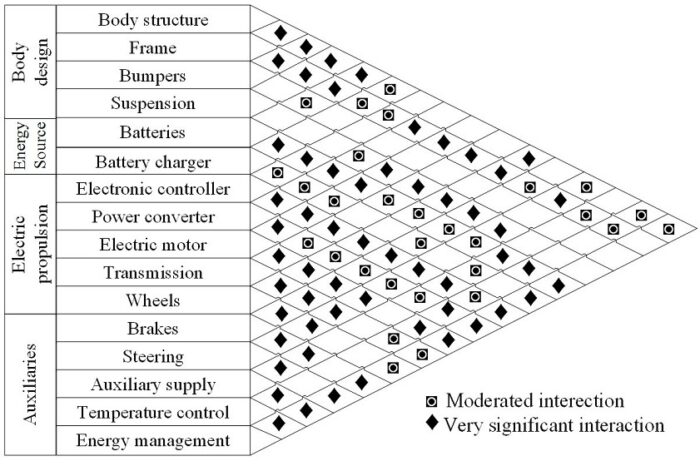

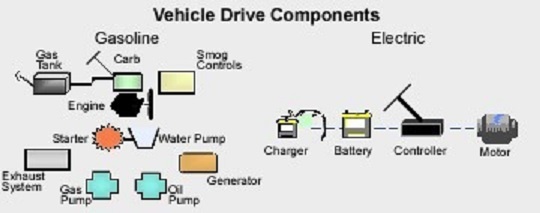

The engine of a conventional internal combustion engine car is replaced by an Electric Motor and the fuel tank is replaced by the Battery Pack. Of all the components only the Battery Pack and Electric Motor alone contributes to about more than 50% of the total EV’s weight and the price.

__

Section-1

Prologue:

A car can be a wonderful thing. It can take you where you want, when you want — even when those places aren’t served by public transportation. In fact, much of modern life would be impossible without cars. They help us get to our jobs, schools, grocery stores or even just to the local shopping mall. Unfortunately, as wonderful as cars are, they also have some serious drawbacks. Two of these drawbacks are that they often cost a lot of money to maintain and they pollute the atmosphere with noxious gases.

Few people would advocate giving up cars altogether, but is there a way we can have the power and convenience of an automobile without the pollution and expense caused by burning gasoline? Fortunately, there is. Many people think that the cars of the not-so-distant future will be powered not by gasoline, but by electricity. In fact, these electric cars — also known as EVs or electric vehicles — aren’t futuristic at all. In the early 1900s, the electric vehicle was reserved for dignitaries the likes of Thomas Edison, John D. Rockefeller, Jr. and Clara Ford, the wife of Henry Ford. They chose this transportation for its quiet ride over the vibrating and polluting internal combustion engine. Although electric vehicles have been around since the first half of the 19th century, even today internal combustion engines still rule in most of cars. Out of 1.4 billion cars on road worldwide in 2020, only 7 million are electric vehicles. An electric vehicle (EV) uses electric motor powered by rechargeable battery for propulsion. Because it runs on electricity, the vehicle emits no exhaust.

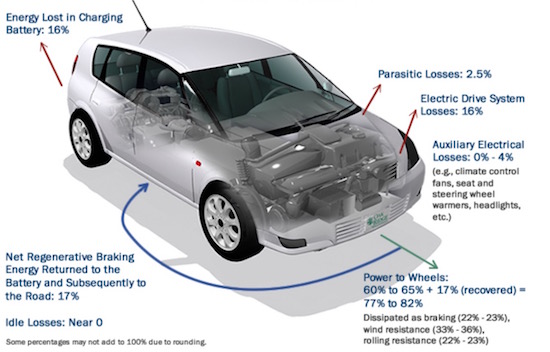

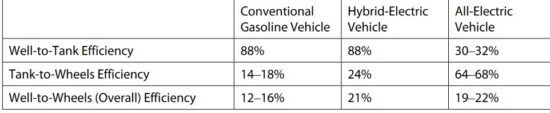

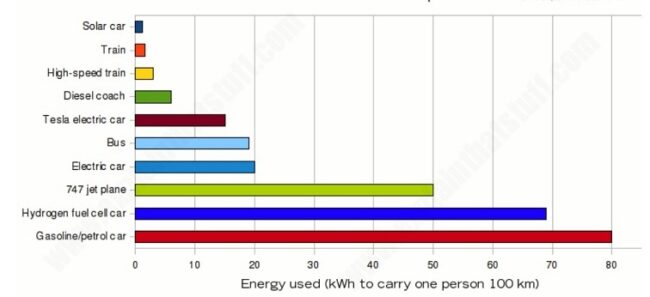

Most of the vehicles are powered by internal combustion engines (ICEs) that burn fossil fuels to create the mechanical energy required to drive them forward. Gasoline or diesel goes in, tiny explosions power pistons and turn a crankshaft, the car moves forward, and carbon dioxide goes out. But not all of the energy trapped in the fuel actually gets used to move the vehicle along the road. In fact, for a typical gasoline-powered car, only about 14-16 percent of the energy stored in gasoline is converted to power at the wheels. Over 80 percent of the fuel’s energy is lost in the internal combustion engine. ICEs are very inefficient at converting the fuel’s chemical energy to mechanical energy, losing energy to friction, pumping air into and out of the engine and wasted heat. In comparison, electric vehicles convert between 59 and 62 percent of the electrical energy from the grid to power at the wheels.

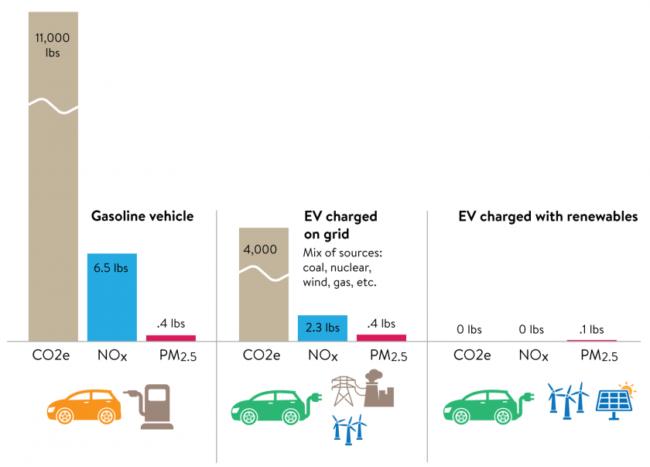

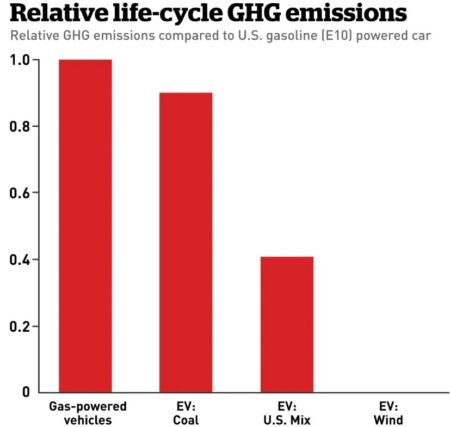

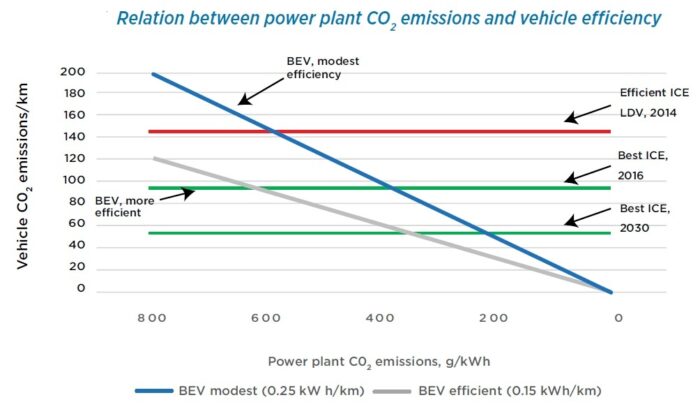

Among many innovative technologies to decarbonize urban transport, electrification of the vehicle fleet has been viewed by many as an effective way to reduce carbon emissions, energy consumption, air pollution, and oil dependence. Electric vehicles (EVs) have the benefits of zero tailpipe emissions, low engine noise, and higher propulsion efficiency, and many governments have demonstrated their commitment to electromobility, particularly in populated urban areas with severe air quality problems. However, the energy consumption, CO2 emission and air pollution during the generation of the electricity used to power EVs cannot be neglected.

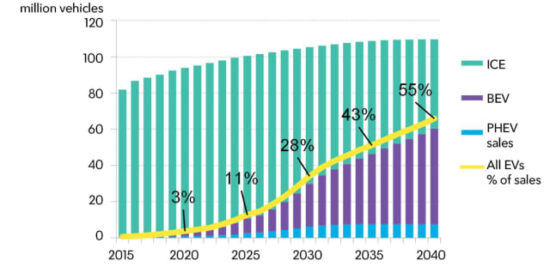

The EV is said to replace cars with the internal combustion engine by ca. 2040. The International Energy Agency (IEA) anticipates that there may be 300-400 million EVs on the road out of approximately 2 billion vehicles by 2040. However, certain drawbacks have hindered wider acceptance of EVs; they have shorter driving ranges than gasoline vehicles, are more expensive and take a long time to recharge. The future of electric vehicles depends largely on a combination of high government subsidies, extremely high gasoline prices, and dramatic improvements in battery technology. Proponents of government subsidies argue electric vehicles generate a range of short-term and long-term benefits such as reduced environmental impacts, innovation spillovers, and reduced reliance on imported oil. Several technological improvements will be needed to make the electric powertrain practical and economical. Even with oil at $100 a barrel, the price of the EV batteries would need to fall significantly to make battery powered electric vehicles competitive with conventional gasoline-fueled vehicles.

_____

Note:

This article focuses on electric car and the term electric vehicle is used synonymously with electric car, although the term electric vehicle also includes road (electric buses, trucks, bicycles, motorcycles and scooters) and rail vehicles, surface and underwater vessels, electric aircraft and electric spacecraft.

______

______

Abbreviations and Synonyms:

Li-Ion = Lithium Ion

Na-NiCl2 = Molten Salt

Ni-MH = Nickel Metal Hydride

Li-S = Lithium Sulphur

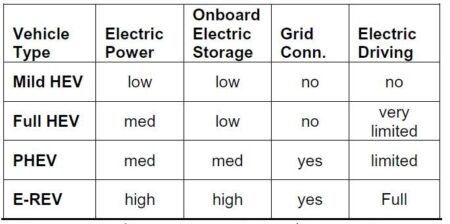

E-REV = Extended-Range Electric Vehicles

AC = Alternating Current

Amp = Ampere-unit of electrical current

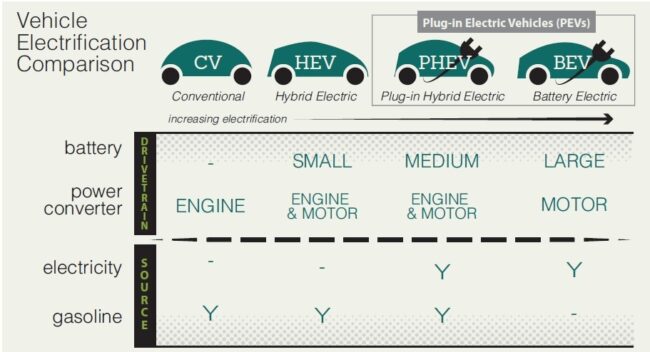

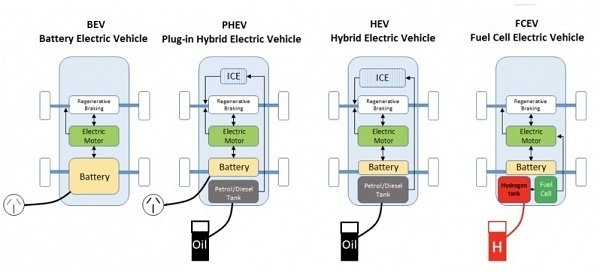

BEV = Battery Electric Vehicle = All-electrical vehicle

HEV = Hybrid Electric Vehicle

Hybrid = A vehicle with an electric motor & batteries plus an ICE

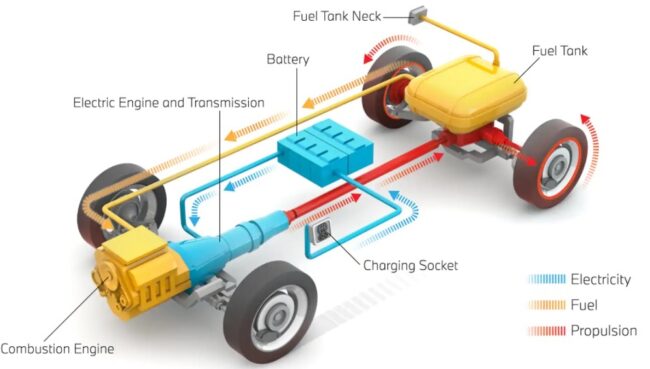

PHEV = Plug-in Hybrid Electric Vehicle

PEV = Plug-in Electric Vehicle = BEV + PHEV

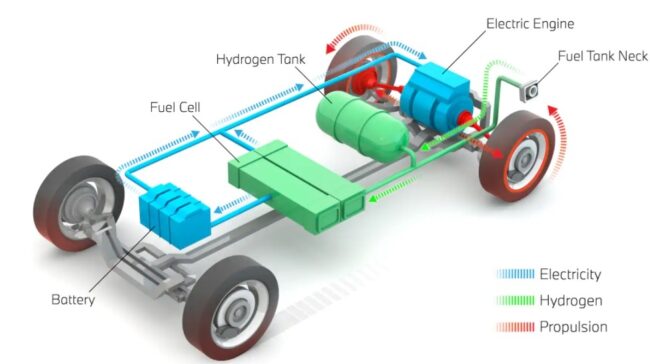

FCEV: Fuel Cell Electric Vehicle

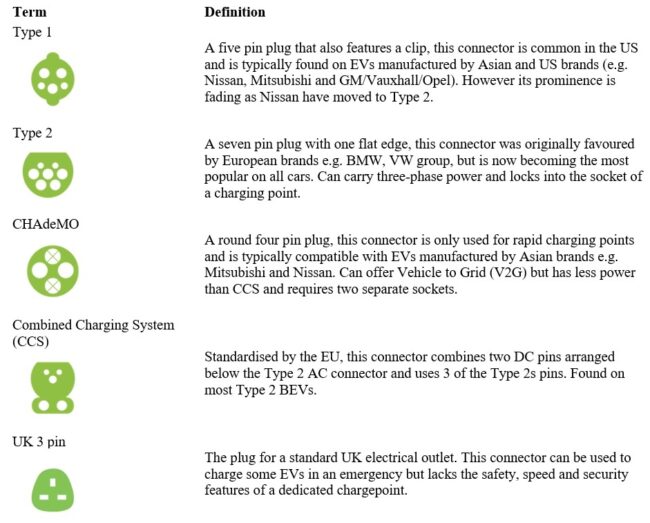

CCS = Combined Charging System (a type of rapid charger)

CHAdeMO = An abbreviation of “CHArge de MOve” (a type of rapid charger)

DC = Direct Current

EV = Electric Vehicle

CV = Conventional or Combustion Vehicle

ZEV = zero-emissions vehicle

EVSE = Electric Vehicle Supply Equipment (chargers outlets and cables)

ICE = Internal Combustion Engine

kW = kilo Watt (unit of power)

kWh = kilo Watt hour (unit of energy)

PV = Photovoltaic Solar Panels

Regenerative Braking = Using electric motor as generator to slow vehicle & recharge batteries

REX = Range Extending

RFID = Radio Frequency ID (tech used by many charge cards)

SoC = State of Charge (the percentage on your battery)

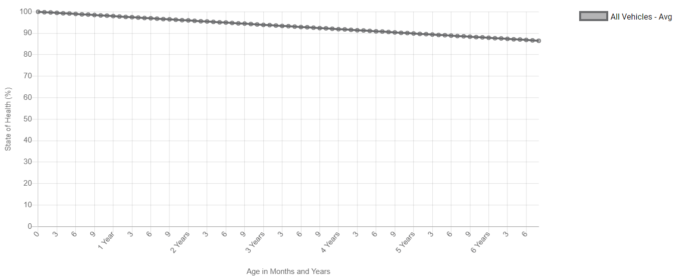

SoH= State of Health of battery

V2G = Vehicle to Grid (sending energy from EV back to the grid)

UCS = Union of Concerned Scientists

HV = high voltage

LV = low voltage

BMS = battery management system

TMS = thermal management system

Gas = gasoline = petrol

IRENA = International Renewable Energy Agency

VRE = variable renewable energy

Tyre = Tire (For British motorists, the rubber wheel-covering is called a tyre – for the Americans it’s a tire)

EV generally means BEV unless specifically stated.

______

______

Section-2

Electric vehicle terminology:

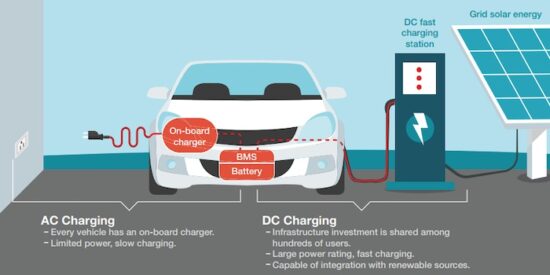

Charging- EV owners need to recharge their EV batteries using electricity, instead of visiting a petrol station and refueling.

Charging point- Locations where an EV can be charged. These charging points can be at home, at work, in designated parking spots in public spaces and so on.

Top Up Charging- The practice of plugging in your electric vehicle whenever you park while out and about, making use of the time your car is not in use to add charge to your battery. This helps avoid range anxiety and means you will rarely find yourself waiting for your car to charge.

Home Charging- Plugging your electric car in to charge while it is parked at home, typically overnight. A dedicated home charging point is the best and safest way of doing this.

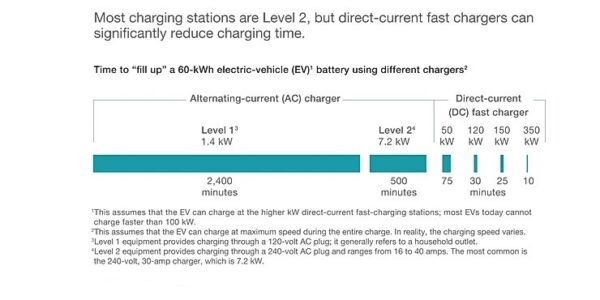

En-route Charging- En route charging typically requires high powered rapid chargers, that put >100 miles into your electric car in the time it takes to grab a coffee, a snack and use the facilities. This enables you to take long-distance trips in your electric car, but is not needed day-to-day.

ICEd- When a chargepoint is occupied by a vehicle with an internal combustion engine (ICE), preventing an EV from charging. A polite note left on their windscreen with your phone number is generally the best response.

Smart charging- A catch-all term for a series of functions that a Wi-Fi connected charge point can perform. Typically this refers to things like load balancing, energy monitoring and “managed charging”, i.e. shifting charging periods away from periods of high grid demand and/or low grid supply and to periods of low grid demand and/or high grid supply.

Vehicle to Grid (V2G)- The concept of using your electric car battery to release power back through the charger either for use in the local building or back into the grid at large during time of high grid demand.

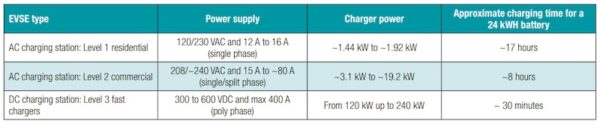

Single-phase Power- Typically found in most homes and some businesses, this is what all standard 3 pin plug sockets provide. A single-phase AC electricity supply can power a dedicated charge point up to 7kW.

Three-phase Power- Often found on commercial and industrial sites, this provides three alternating currents and allows for 22kW AC charging. Significant three-phase power availability is also a prerequisite for DC rapid charger installation.

Reduction gear- This is the type of transmission on EVs. Because EVs can deliver their max power immediately and can sustain over 20,000 RPM, they only need one gear to deliver a great balance of acceleration and top speed. Once you lift off the accelerator, the reduction gear assists in slowing down the EV.

Regenerative braking- In a battery-powered vehicle, regenerative braking is when the otherwise wasted kinetic energy produced during braking is harvested and stored as chemical energy inside the battery. This energy can then be used as power. This helps EVs become even more efficient and can help extend their range.

EV Incentives- Usually provided by state or central governments to encourage buyers to purchase EVs. Incentives include subsidies in purchase price, tax credit, free parking, zero or reduced road tax among other exemptions.

Zero Emissions- An emission standard where EVs emit zero tailpipe pollutants. ICE powered cars release harmful gases like carbon monoxide ad nitrous oxide. A zero-emission vehicle is completely carbon neutral.

Range- The distance you can travel on pure electric power before the battery requires a recharge.

Range Anxiety- A term used to describe the fear of running out of battery power while driving an EV. This fear can be avoided by top-up charging wherever you park throughout the day and en-route charging on longer journeys. After becoming familiar with owning and driving an EV for a short time, many people find that range anxiety becomes range awareness and they no longer have a fear of running out of energy.

Aftermarket conversions- An aftermarket electric vehicle conversion is the modification of a conventional internal combustion engine vehicle (ICEV) or hybrid electric vehicle (HEV) to electric propulsion, creating an all-electric or plug-in hybrid electric vehicle.

New energy vehicles- In China the term new energy vehicles (NEVs) refer to vehicles that are partially or fully powered by electricity, such as battery electric vehicles (BEVs), plug-in hybrids (PHEVs), and hydrogen fuel cell vehicles (FCEVs). The Chinese government began implementation of its NEV program in 2009 to foster the development and introduction of new energy vehicles.

NVH stands for Noise, Vibration and Harshness, and is basically a measure of how much unpleasant aural and tactile feedback the car delivers as you drive.

_____

Ah- This stands for ‘amp hours’ and will usually be presented with a number in front of it, e.g., 320 Ah. Amp-hours are often used to measure the charge of a battery. A charge of one Ah will supply one amp of current for one hour.

kWh- Kilowatt-hour. A unit of energy equivalent to the energy transferred in one hour by one thousand watts of power. Electric car batteries are typically measured in kilowatt hours. It is a unit of energy describing a battery’s capacity and how much energy it has to provide to the car’s electric motors. The larger the number of kilowatt-hours, the bigger the battery, the longer a car’s range. 1 kilowatt hour is typically 3-4 miles of range in a BEV. One kWh is one unit in your electricity bill. kWh divided by voltage gives you Ah for a given battery.

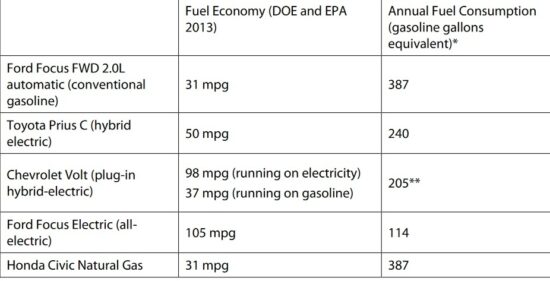

kWh mileage estimates the number of miles you get per kWh (e.g., 3.5 miles/kWh). It’s interesting to see the wide range of mileage you can get based on the size and weight of your car, where and how you drive it, and when you charge. Electric vehicles get worse mileage at faster speeds, largely due to the loss of regenerative braking and single gear transmission. The EPA has estimated one gallon of gas to be 33.7-kilowatt hours (kWh). The EV mileage is better than that of an equivalent gas-powered car for following reasons: (1) When grid has a good amount of clean energy on it, which gives the EV “free” miles; (2) The gas is being burned in a relatively efficient power plant, rather than in a relatively inefficient gas engine; (3) Electric-drive motors are much more efficient than combustion engines and drivetrains; and (4) The electric car regenerates power from braking, which a traditional gas-powered car cannot do. (Hybrids also do this.)

Range per hour (RPH)- Miles of range per hour of charge.

MPGe- MPGe stands for “miles per gallon gasoline equivalent” and is supposed to represent how many miles an electric vehicle is estimated to be capable of traveling on the amount of energy contained in a gallon of gas, which is 33.7 kWh according to the EPA. A higher MPGe rating means a car is more efficient, which is better. But battery capacities are all over the place, so more MPGe doesn’t yet correlate with more range. An inefficient vehicle with a big battery may be more usable than one that’s efficient, but has a smaller battery.

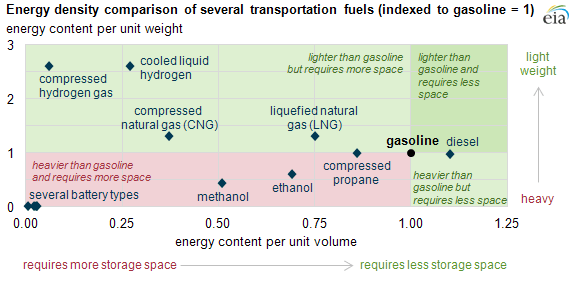

Specific energy- In terms of calorific value per weight, a battery generates only 1 percent of what fossil fuel produces. One kilogram (1.4 liter, 0.37 gallons) of gasoline yields roughly 12kWh of energy, whereas a 1kg battery delivers about 150Wh. However, the electric motor is 90 percent efficient while a modern ICE comes in at about 15-20 percent.

____

Measure of electric range and efficiency:

Information about an electric car’s range is never complete without one of the following acronyms in close proximity: NEDC, WLTP, or EPA. These are the world’s three most predominantly used test protocols, and they say a lot about whether an electric car can actually achieve what its manufacturer claims in range. But different protocols give different results, so it’s important for you to know when an automaker is trying to play you for a fool by promoting the results of a test that puts its products in the most favorable light possible.

NEDC

NEDC, or “New European Driving Cycle,” is a test method last updated in 1997, meaning it predates the Toyota Prius. Even in its day, the NEDC protocol was accused of creating MPG figures you could never replicate in the real world. For electric vehicles, any range results from an NEDC-cycle test will be inflated and likely impossible to achieve out on the road without severe hypermiling. Thankfully, most of Europe and Asia abandoned this obsolete test method in favor of WLTP-protocol tests in 2017, though a few automakers still rate their EVs’ ranges with the flattering NEDC ruler.

WLTP

The Worldwide Harmonized Light Vehicle Test Procedure, shortened to WLTP, is the test method in use today across most of Europe and Southeast Asia. Though it replaced the flawed and long-outdated NEDC system, WLTP still has its detractors, as its range ratings for EVs are still on the generous side. In theory, you can drive your EV as far as the WLTP says you can, but it’ll still be something of an inconvenience.

EPA (United States Environmental Protection Agency)

Environmental Protection Agency is in charge of determining domestic fuel economy ratings, and that means estimating EV ranges also falls under its purview. Compared to the other two major testing protocols, the EPA is the most conservative with its results, estimating shorter ranges for EVs than you get from either WLTP or NEDC testing. This is in part due to highway driving, where EVs are less efficient, making up a larger proportion of North Americans’ driving, and thus a bigger chunk of the EPA test than in WLTP or NEDC tests. If you live in America, the EPA’s numbers are the ones to recognize. Demand EPA test results. If you’re elsewhere, abide by WLTP. But regardless of where you live, always look for test protocol behind the promised range, because how you reach a result is just as important as the result itself.

______

______

Section-3

Basic science vis-à-vis electric vehicle:

_

Volt:

Think of the volt as a measurement of electrical “pressure,” like you’d find in a common garden hose. For a given diameter of hose, turning up the pressure moves more water. (Water is equivalent to power in this analogy.)

Ampere:

Continuing the garden hose analogy, think of the ampere (aka amp) as a measurement of electrical “flow,” with a larger-diameter hose—higher amperage—flowing more water (electrical power) at any given pressure (voltage).

Watt:

Named for James Watt, who also defined the term “horsepower,” the watt is a measure of the expenditure of energy over time. One watt is one joule per second, and is used to quantify the rate of energy transfer. One horsepower is equal to 745.7 watts.

Kilowatt:

The kilowatt is just 1,000 watts. Watts are small, so a bunch of them need to be grouped up to have meaning in the world of vehicle-level power: One kilowatt is equal to 1.34 horsepower.

Horsepower:

A unit originally invented to aid in the sales and marketing of steam engines, by measuring the output of the then-new machines in familiar, easy-to-understand terms. Like the watt, the horsepower is a measure of the delivery of energy over time.

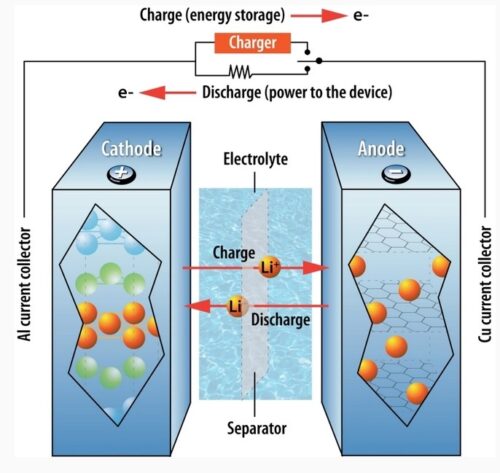

Lithium-ion:

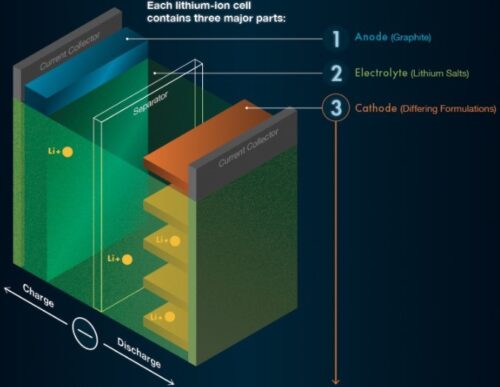

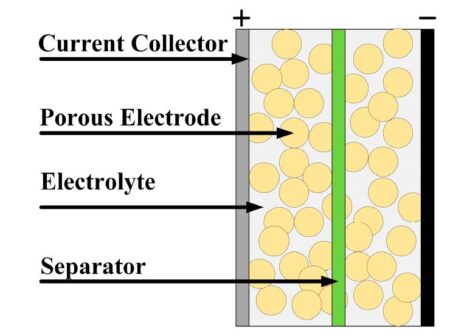

A blanket term covering many different formulations of battery. In the most basic terms, a lithium-ion battery is any battery that uses a lithium-based cathode (positive electrode). In the charging process, negatively charged electrons are supplied to the anode (negative electrode), drawing charged lithium particles (ions) through an electrolyte from the cathode to the anode, where they are stored. When the battery discharges, the ions move back to the lithium cathode, freeing the stored electrons to move, generating electricity. A separator prevents current from traveling within the battery.

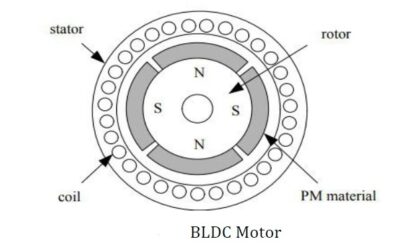

Rotor:

The rotor is, as the name implies, the rotating bit in an electric motor. Think of it kind of like the crankshaft of a combustion engine; forces in the motor cause the rotor to spin, and that spinning is the motor’s output.

Stator:

The fixed parts surrounding the rotating part of an electric motor. The stator causes the rotor to spin by creating a constantly rotating magnetic field around its circumference. This rotating magnetic field interacts with the rotor’s magnetic field, causing it to spin.

Permanent-magnet synchronous motor:

The rotor’s magnetic field is supplied by permanent rare earth magnets, and it rotates in sync with the stator’s rotating magnetic field, hence the “synchronous” part of the name.

Induction asynchronous motor:

Instead of permanent magnets, induction motors use electrical current to induce a magnetic field in a cage of metal bars on the rotor, similar to how an electromagnet works. In order for that electromagnetic induction process to happen, there has to be some slight misalignment between the fields of the stator and the metal bars on the rotor. This misalignment is known as “slip,” and it’s also what makes the motor “asynchronous.”

CO2e:

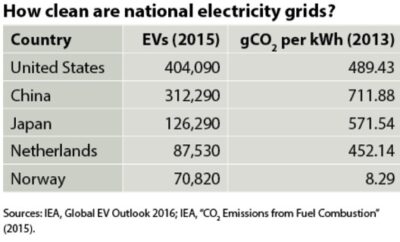

Different energy sources produce different global warming emissions. Carbon dioxide (CO2) is the most prevalent of these emissions, but other air pollutants—such as methane—also produce global warming. To make comparisons easier, we convert the global warming potential of all emissions to units of carbon dioxide equivalent, or CO2e—the amount of carbon dioxide required to produce an equivalent amount of warming. This lets us compare gasoline emissions with emissions from the electricity grid, even when the chemical nature of the air pollution is different. A higher number of CO2e emissions leads to more warming. Battery-electric vehicles provide zero-vehicle-emissions driving (for both carbon dioxide (CO2) and pollutant emissions), but the “upstream” CO2 can be substantial, for example in countries with dominant coal power generation. Electric grids must be considerably decarbonised (to 600 grams/ kWh or less) for EVs to have a CO2 advantage relative to similar sized hybrid internal combustion engine (ICE) vehicles.

______

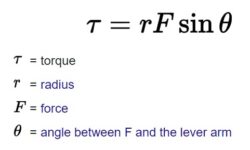

Torque:

Torque is the measure of the force that can cause an object to rotate about an axis. Force is what causes an object to accelerate in linear kinematics. Similarly, torque is what causes an angular acceleration. Hence, torque can be defined as the rotational equivalent of linear force. It’s important to note that torque is independent of movement or time; torque can be applied at zero rpm. To make sense of that, think about turning a doorknob until it stops and then holding it there. The force you used to turn it is torque, and so is the force you’re using to hold it, even though the doorknob is no longer rotating.

_

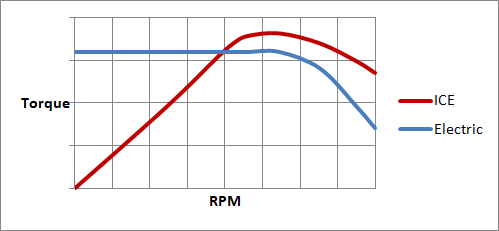

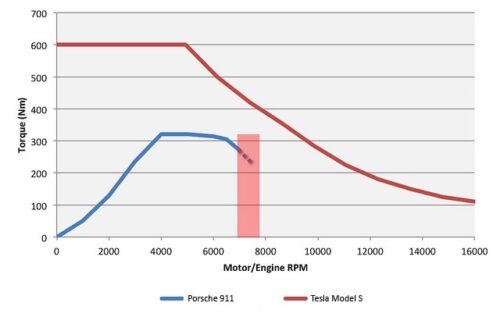

Torque comparison graph for an electric motor and gasoline engine of similar maximum power:

Figure above shows rough indication of how torque varies with speed (engine rpm) for electric motors and gasoline engines of comparable power. Electric motors produce maximum torque right from the off, whereas gasoline engines need to pick up quite a bit of speed to deliver maximum torque. Most of the driving is done in the 2200 to 4800 rpm range with significant amount of torque. Lower rpms require torques as high as 125 Nm; urban vehicles have to operate in this region regularly as they face frequent start-stops.

_

In the case of electric cars, they produce their maximum torque output straight out of the bat. That means you have access to the entire torque output straight from standstill. It only starts decreasing as you progress towards the upper RPM range due to the phenomena of back EMF. Electric cars only consist of one intermediate part between the wheels and the motor, the transmission. Hence, they produce a really high torque output and experience negligible output loss at the same time. For a comparative figure, a Chevrolet Bolt electric city hatchback produces 360 Nm of torque which is as much as a Nissan 370Z V6-powered coupe!

______

Regenerative braking:

When breaking in a traditional car, the kinetic energy caused is lost – mainly in the form of heat as the brake pads of the car heat up due to friction of the brake pad on the brake disc. However, in an electric car the electric traction motor uses the vehicle’s momentum to recover energy that would otherwise be lost to the brake discs as heat. So in regenerative braking an electric motor functions as an electric generator to slow car & recharge batteries.

Regenerative braking allows the range of the EV to be extended; however, the efficiency of capturing this energy is reported to vary from 16% to 70% (Boretti, 2013). This simply means that 16 to 70% of the kinetic energy lost during the act of braking can be turned back into acceleration later.

______

Battery:

A battery is a device for storing chemical energy and converting that chemical energy into electricity. A battery is made up of one or more electrochemical cells, each of which consists of two half-cells or electrodes. One half-cell, called the negative electrode, has an overabundance of the tiny, negatively charged subatomic particles called electrons. The other, called the positive electrode, has a deficit of electrons. When the two halves are connected by a wire or an electrical cable, electrons will flow from the negative electrode to the positive electrode. We call this flow of electrons electricity. The energy of these moving electrons can be harnessed to do work — running a motor, for instance. As electrons pass to the positive side, the flow gradually slows down and the voltage of the electricity produced by the battery drops. Eventually, when there are as many electrons on the positive side as on the negative side, the battery is considered ‘dead’ and is no longer capable of producing an electric flow.

The electrons are generated by chemical reactions, and there are many different chemical reactions that are used in commercially available batteries. For example, the familiar alkaline batteries commonly used in flashlights and television remote controls generate electricity through a chemical reaction involving zinc and manganese oxide. Most alkaline batteries are considered to be a disposable battery. Once they go dead, they’re useless and should be recycled. Automobile batteries, on the other hand, need to be rechargeable, so they don’t require constant replacement. In a rechargeable battery, electrical energy is used to reverse the negative and positive halves of the electrochemical cells, restarting the electron flow.

There are many types of battery chemistry available. Broadly batteries can be classified into three types.

Primary Batteries: These are non-rechargeable batteries. That is, it can convert chemical energy to electrical energy and not vice-versa. An example would be the Alkaline batteries (AA, AAA) use for toys and remote controls.

Secondary Batteries: These are the batteries in which we are interested in for electrical vehicles. It can convert chemical energy to electrical energy to power the EV and also it can convert electrical energy to chemical energy again during the charging process. These batteries are commonly used in mobile phones, EV’s and most of the other portable electronics.

Reserve Batteries: These are special type of batteries used in very unique application. As the name states the batteries are kept as reserve (standby) for most of its life time and hence have a very low self-discharge rate. Example would be Life vest batteries.

_____

Amp Hour and Kilowatt Hour:

Amp Hours are a measure of electric current and kilowatt-hour(kWh) is a unit of energy (it shows how much energy has been used), e.g., a 100 watt lightbulb uses 0.1 kilowatts each hour. An average home consumes 3,100 kWh of energy a year. An electric car consumes an average of 2,000 kWh of energy a year.

Consider the following…

A battery rated for 100 amp hours will provide 5 amps for 20 hours. If we have a 12 volt battery, we multiply 100 by 12 and determine that the battery will provide 1200 watt hours. To apply the metric ‘kilo’ prefix, we divide the result by 1000 and determine that the battery can supply the 1.2 KW hours.

There is something to keep in mind. The Amp Hour rating is a 20 Hour rating, therefore it is necessary to treat any kilowatt conversion you make as a 20 hour rating as well.

Limitations on Kilowatt Hours as Tool:

Like Amp Hours, the Kilowatt Hour specification is a typically 20 hour rating. Like Amp Hours, the Kilowatt Hours are subject to a phenomenon known as Peukert’s Law. What this phenomenon describes is the fact that any increase in the current draw on the battery will also result in a decrease on capacity. Similarly decreasing the current draw will result in an increase in battery capacity. More, the relationship is not linear. From a practical perspective, this means the Kilowatt Hour rating is difficult to extrapolate when value as the current draw increases.

Kilowatt Hours and Series Batteries Systems:

In some systems, 12 volt batteries will be connected in series (end to end) to create a higher voltage. For example, two 12 volt batteries in series will provide 24 Volts.

Suppose two 12 volt batteries rated at 100 Amp Hours were connected in series. While the voltage would increase to 24 Volts, the Amp Hours would remain the same. While amp hours remain the same, voltage does not. That means the power capacity has increased. In the case of our 100 Amp Hour series batteries, the Watt Hours have increased to 2.4 kWh. This particular characteristic can be a contributor to choosing 24 Volt Systems.

______

kW and kWh

The simplest definitions of kW and kWh are as follows:

kW = one thousand watts (and a watt is one joule of energy per second)

kWh = using a thousand watts for an hour (3,600,000 joules).

That may make kW and kWh look like they’re easily connected, but kW (kilowatts) and kWh (kilowatt hours) are not compatible units, so cannot be compared. Kilowatts are a unit of power, while kWh is a unit of energy. Think of it this way: kW defines how much energy a device uses or generates in a given amount of time. Meanwhile kWh defines how much energy that device actually used or generates. So, a 100-watt light bulb that is on for 10 hours needs 1 kWh (1,000 watt-hours). This is the same as ten 100-watt bulbs burning for one hour.

A kilowatt hour is a measure of energy used by an appliance if it were kept running for one hour. It’s not how many kilowatts are being used per hour! A kilowatt however, is a measure of instantaneous power. Appliances like televisions, computers, fridges, and electric car motors all have a watt or kilowatt rating. This is a measure of how much power they need to be continuously supplied with in order to run.

Let’s say you have an electric motor rated at 200 kilowatts (kW) at peak power output. If you ran that motor for 30 minutes you would use 100 kWh of energy — 200 multiplied by 0.5 (of an hour) equals 100 kWh.

Both kW and kWh are SI (metric) units and can be applied to any type of machine or energy storage system respectively. That means a gas engine or electric motor can both have a kW rating. Similarly since kWh is a measure of energy, you can define the capacity of a tank of liquid fuel or a battery in kWh.

In battery terms, a kWh rating defines how much energy the battery pack has available to provide to the electric motor and, thus, sort of, how far the car can go before needing to be recharged. In order to make batteries last longer (in terms of durability rather than range) they are typically not used to their full capacity. GM engineers have opted to only use half of the capacity of the Chevy Volt’s 16 kWh battery pack in order to help it last for 10 years / 150,000 miles. That means it will only provide 8 kWh of usable energy to get a 40-mile nominal electric-only range.

Still, since we don’t know the usable capacity of all the battery packs used in plug-in vehicles, we’ll use total capacity to compare some of the more popular EVs:

|

Model |

Battery Capacity |

EV Range (official estimates) |

Miles per kWh |

|

Chevy Volt |

16 kWh |

40 miles |

2.5 |

|

Ford Focus BEV |

23 kWh |

75 miles |

3.2 |

|

Tesla Model S (base model) |

42 kWh |

160 miles |

3.8 |

|

Nissan Leaf |

24 kWh |

100 miles |

4.1 |

|

Tesla Roadster |

53 kWh |

244 miles |

4.6 |

|

Citroën C-ZERO |

16 kWh |

80 miles |

5 |

|

A123 PHEV Prius |

5 kWh |

30-40 miles (top speed, 35 mph) |

6-8 |

Note that these battery packs are being used in very different types of vehicles, which accounts for some of the difference in miles per kWh.

Be mindful of these numbers since, the Volt only uses 50 percent of its capacity while the Tesla Roadster can use 100 percent of its 53 kWh. The Tesla battery pack is only expected to retain at best about 70 percent of capacity after 4-5 years while the Volt is being developed to still have 100 percent of its rated capacity after 10 years.

In battery terms, a kWh rating tells us how much energy the pack has to give to the electric motor. So, the 24 kWh pack in the Nissan Leaf could provide 24 kW for one hour, not taking into account what it’s actually being asked for by the electric motor or what connectors are in it to regulate the flow.

Batteries are in a unique position compared to many other devices. While they are primarily energy storage devices measured in kWh, they also have power ratings in kW. The power rating of a battery describes how fast it can release or absorb energy. Think of it in terms of a fuel tank. A high capacity, low power battery would be like a big tank with a pin-hole for the fuel to pour out of. A high power battery would have a larger opening for the fuel to come out of (or go into). Telsa’s Powerwall 2, for example, has a continuous output capacity of 5kW (higher rates possible for short periods) and a storage capacity of 13.2kWh (at the beginning of its warrantied life).

This brings us to electric motors, which are also given a kW rating. If you’re coming to EVs from standard gasoline vehicles, understanding a motor’s kW rating is simpler than understanding kWh because a kilowatt is equal to around 1.34 horsepower. Therefore, it is possible (and easy) to translate electric motor strength into hp, more commonly used to define liquid-powered engine power. A 100 kW motor puts out 134 hp. The higher the kW figure, the more oomph you’ll get at the expense of energy consumption.

The following list shows the power ratings of EVs motors that aren’t too different when compared with similar sized and performing ICE vehicles.

Nissan Leaf – 110kW

Hyundai Kona Electric – 150kW

Mercedes-Benz EQC – 300kW

Porsche Taycan Turbo S – 560kW

Tesla Model S Performance – 595kW

The electric propulsion system has better torque with the same horsepower than the ICE. This is reflected in excellent acceleration.

Brake horsepower = Traditionally ‘brake horsepower’ (bhp) has been used as the definitive measurement of engine power. It’s distinct from horsepower because it takes into account power loss due to friction – it’s measured by running an engine up to full revs, then letting it naturally slow down to a dead stop. Ford’s new Mustang Mach-e is more than 330bhp on tap and a 0-60mph time of just over five seconds.

_____

Cost Per Mile:

One reason it’s important to understand all of this is that it will help to determine how much it will cost you to drive your plug-in vehicle. Right now, knowing your mpg and the cost of gasoline will do the trick. Determining the cost per mile of an EV requires knowing your utility’s rates and how much juice your car will require to fill up. For example, a charger that uses two kW and takes eight hours draws 16 kWh of electricity. If your utility charges a dime per kWh, then to “fill up” costs you $1.60. Then, you take this number and divide it by how far you can go on to determine your cost per mile.

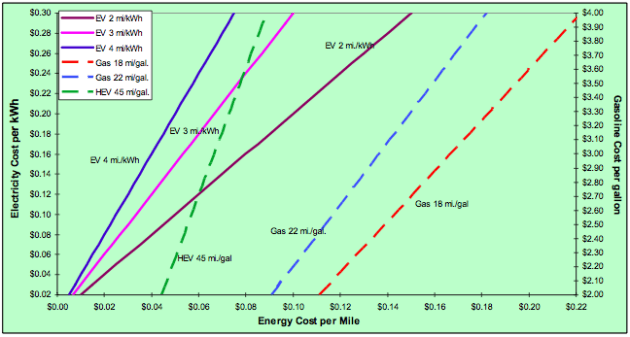

The Idaho National Lab has also provided a handy chart for this. It’s slightly out of date because it can only help us calculate costs for an EV that get 2, 3, or 4 miles per kWh, but if gives you can idea. Here’s how to read the chart:

The fuel cost of driving an electric vehicle depends on the cost of electricity per kilowatt-hour (kWh) and the energy efficiency of the vehicle. For example, to determine the energy cost per mile of an electric vehicle, select the location on the left axis (Electricity Cost per kWh) at 9 cents in the graph above. Draw a horizontal line to the right until you bisect the EV 3 mi/kWh line. Now draw a vertical line down until you bisect the bottom axis (Energy Cost per Mile). This tells you that the fuel for an electric vehicle with an energy efficiency of 3 miles per kWh costs about 3.0 cents per mile when electricity costs 9 cents per kWh.

_____

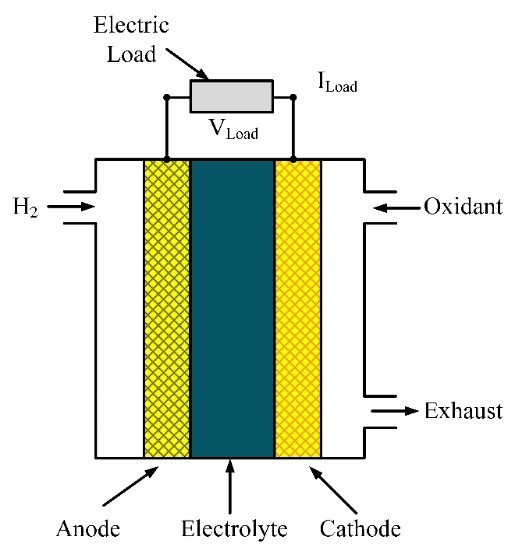

kW and Hydrogen Fuel Cells:

Just as with any other machine, kilowatts are also used to explain the output of a fuel cell stack. Unlike a battery, the stack does not store energy, it simply transforms it from chemical to electrical. Therefore the power rating describes the rate at which it can produce electrical energy. The power output range varies tremendously depending on what kind of fuel cell we’re talking about. Proton Exchange Membrane (PEM) fuel cells are often used in hydrogen cars, and generally range from 50 to 250 kW. Since fuel cells send their electricity to the electric motor, the kW rating of the motor defines how much of this energy is actually required at any given moment. And, instead of being limited by the kWh in the battery pack, the range of a hydrogen car is limited by the amount of fuel in the storage tank which can also be defined in terms of kWh (1 kg of compressed hydrogen gas has a capacity of about 39.7 kWh).

______

Where does the electric energy go in electric car?

______

______

Section-4

Global activity to phase out Internal Combustion Engine Vehicles:

Internal combustion engine vehicles (ICEVs) have experienced continuous development in manufacturing technology, materials science, motor performance, vehicle control, driver comfort and security for more than a century. Such ICEV evolution was accompanied by the creation of a huge network of roads, refuelling stations, service shops and replacement part manufacturers, dealers and vendors. No doubt, these fantastic industrial activities and business have had a central role in shaping the world and, in many aspects, the society as well. Today, the number of ICEV models and applications is astonishing, ranging from small personal transport cars to a hundred passenger buses, to heavy load and goods transportation trucks and heavy work caterpillars. Modern ICE vehicles encompass top comfort, excellent performance and advanced security, for relatively low prices and, needless to say, have become since the beginning the most attractive consumer products. However, despite approximately a century-long industry and academia struggle to improve ICE efficiency, this is, and will continue to be, incredibly low. About 15-20% of the energy produced in the ICE combustion reaction is converted into mechanical power. In other words, approximately 80% of the energy liberated by combustion is lost. In fact and worse than that, the wasted energy of thermal motors, as ICEs may be called, is transformed into motor and exhaust gases heat. The exhaust gases are a blend formed mostly of carbon dioxide (CO2) and, to a lower extent, nitrogen oxides (NOx), hydrocarbons (CxHy), carbon monoxide (CO) and soot. Carbon dioxide is known to block the earth’s radiation emissions back into the outer space thus promoting global temperature rise – the so-called greenhouse effect. This, climate researchers say, is silently creating other global catastrophic changes, as for example, sea level rise. Air pollution in big cities is another serious problem caused by exhaust gases, which leads to respiratory system diseases, including lung cancer. Disturbing noise level is another issue related to big fleet of ICEVs in big cities. Yet, this brings about another headache for city administrators and authorities: the daily jamming, though this last nuisance might be alleviated only by mass transport systems (i.e., subways and trains).

Whether none of the above listed problems ever existed, yet a challenging situation had to be dealt with urgently: the finite amount of fossil fuel available for an ever-increasing world fleet. As petrol wells vanish, this commodity price skyrockets, also motivated by political tension around production areas in Middle East. On the other hand, renewable energy sources, like ethanol produced from sugarcane or maize crops, are an alternative solution being tried in some countries. In Brazil, for instance, sugarcane bio-fuel is an established option, with more than two decades on the road, with ICE automobiles prepared to run interchangeably on gasoline or ethanol automatically. Any driver could choose which fuel type to use at the refuelling station, much based on their prices. There is a criticism over this solution as regards to the demands on food availability and prices, once crop fields are used to produce bio-fuels instead of food. Greenhouse effect gas generation and air pollution problems are still present though to a somewhat lower extent.

_

In light of the Paris Climate Agreement, pollution-related deaths and illness, and magnified devastation from extreme weather, global leaders are pushing to phase out fossil fuel-powered vehicles, which are major contributors to air pollution and climate change. China, Britain, France, India, and other nations have announced plans to phase out vehicles with internal combustion engines (ICE vehicles) and incentivize electric vehicle (EV) use at the national level. Meanwhile, some cities have passed measures to eliminate ICE vehicles within their boundaries by the end of this decade.

_

Reasons for banning further sale of fossil fuel vehicles include: reducing health risks from pollution particulates, notably diesel PM10s and other emissions, notably nitrogen oxides; meeting national greenhouse gas, such as CO2, targets under international agreements such as the Kyoto Protocol and the Paris Agreement; or energy independence. The intent to ban vehicles powered by fossil fuels is attractive to governments as it offers a simpler compliance target, compared with a carbon tax or phase-out of fossil fuels.

_

The automotive industry is working to introduce electric vehicles to adapt to bans with varying success and it is seen by some in the industry as a possible source of money in a declining market. A 2020 study from Eindhoven University of Technology showed that the manufacturing emissions of batteries of new electric cars are much smaller than what was assumed in the 2017 IVL study (around 75 kg CO2/kwh) and that the lifespan of lithium batteries is also much longer than previously thought (at least 12 years with a mileage of 15,000 km annually). As such, they are more ecological than internal combustion cars powered by diesel or petrol.

_

There is some opposition to simply moving from fossil-fuel powered cars to electric cars, as they would still require a large proportion of urban land. On the other hand, there are many types of (electric) vehicles that take up little space, such as (cargo) bicycles and electric motorcycles and scooters. Making cycling and walking over short distances, especially in urban areas, more attractive and feasible with measures such as removing roads and parking spaces and improving cycling infrastructure and footpaths (including pavements), provides a partial alternative to replacing all fossil-fuelled vehicles by electric vehicles. Although there are as yet very few completely carfree cities (such as Venice), several are banning all cars in parts of the city, such as city centers.

_

Passenger cars and vans are responsible for about 15% of European Union (EU) carbon dioxide (CO2) emissions and contribute to high concentrations of air pollutants in many European cities. The COVID-19 pandemic is likely to cause a temporary dip of emissions from passenger cars and vans reflecting a decrease in passenger transport volumes and less traffic. On a local scale, data for March 2020 show that specifically nitrogen dioxide (NO2) emissions dropped significantly in selected European cities affected by strict measures—from social constraints to the lockdown of an entire country—to curb the spread of COVID-19. Yet these restrictive measures are limited to the duration of the coronavirus outbreak, and without more longer-term instruments, emissions from transport are likely to bounce back quickly to previous levels. Early research points to air pollution possibly assisting the spread of COVID-19 and thereby increases the pressure to reduce pollutant emissions from road vehicles and improve people’s health. In addition, mitigating climate change remains a top priority to avoid.

_

Timeline of national targets for full ICE phase out or 100% ZEV (zero-emissions vehicle) car sales:

|

Selected countries |

Year |

|

Norway (100% ZEV sales) |

2025 |

|

Denmark |

2030 |

|

Iceland |

|

|

Ireland |

|

|

Netherlands (100% ZEV sales) |

|

|

Sweden |

|

|

United Kingdom |

2040 |

|

France |

|

|

Canada (100% ZEV sales) |

|

|

Singapore |

|

|

Sri Lanka (100% HEV or PEV stock) |

|

|

Germany (100% ZEV sales) |

2050 |

|

U.S. (only 10 ZEV states) |

|

|

Japan (100% HEV/PHEV/ZEV sales) |

|

|

Costa Rica (100% ZEV sales) |

_

Auto Manufacturer Commitments & Corporate Responsibility:

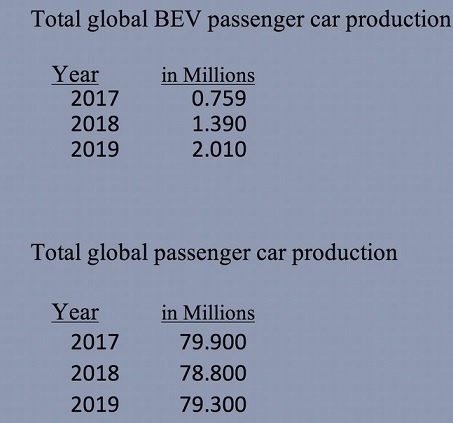

The imposition of emissions limits for vehicle manufacturers in the European Union — calculated on the total number of vehicles sold — has led the traditional car companies to begin switching to electric vehicles as the only way to avoid heavy fines. More and more companies are now considering their engine plants as assets that need to be disposed of urgently, disinvesting at an accelerated pace if emissions targets are to be met. An increasing number of local and national governments are signaling their intention to phase out combustion engine-powered vehicles altogether. In response, car manufacturers are increasingly adapting product strategies away from combustion engines and toward electric power. This comes at a time when combustion-engine vehicles still dominate new car registrations in the European Union. In 2019, gasoline cars accounted for 59% of new passenger car registrations, diesel cars for 31%, conventional hybrid electric vehicles (HEVs) for 5.9%, and cars running on ethanol, liquefied petroleum gas (LPG), and compressed natural gas (CNG) for 1.7%. The share of electric vehicles, including battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs), was 3%.

To meet future demand for EVs, auto manufacturers need to plan and gear up for the relevant changes to design and manufacturing processes. Normally, government calls for reduced vehicle emissions are met with resistance from the private sector. According to Winfried Hermann, transport minister for Stuttgart, “We say, clean up your technology, they say it is impossible.” Nevertheless, many automakers are now planning to sell most of their vehicle fleet in electric versions.

According to Volvo’s CEO, the manufacturer aims for 50 percent of sales to be fully electric by 2025. Other companies including BMW and Renault have committed to significant increases in EV production in the next two years and plan on a full transition in the near future. The PSA Group, which owns Peugeot and Citroen, stated its intentions to electrify 80 percent of its fleet for production by 2023, and Toyota is manufacturing its first fully electrified Prius to meet California’s updated vehicle standards for 2020. Toyota also announced it will be adding more than 10 EV models by the early 2020s, and has partnered with Panasonic to develop a new EV battery. Companies that have already produced fully electrified cars, such as Nissan, are setting the pace by providing more variety to make EVs appealing to consumers with diverse needs. Aston Martin, Jaguar, and Land Rover, producers of luxury cars, have also spoken publicly about their company goals to move toward electrifying vehicles. German-owned makers of Rolls-Royce and Mini Cooper vehicles plan to bring 25 electric models to market by 2025, in line with the goals that several European countries have targeted for the end of new ICE vehicle sales. Additionally, they hope to stay ahead of shifting market demands and the impending European target goals by increasing research and development spending to 7 billion euros. The largest auto manufacturer in Europe, Volkswagen, has pledged 20 billion euros for its electric car program, and its luxury brand Porsche, in collaboration with Audi, will release 20 electrified models by 2025.

Ford Motors and General Motors are also taking the extra step to significantly invest in production efforts. In January 2018, the chairman of Ford announced that the company would more than double their investment in EV production, up to $11 billion, and have 40 models ready for production by 2022, addressing a wide variety of consumers’ aesthetic and logistical needs. Sixteen of the 40 models will function as fully electric cars. In the case of General Motors, one of the largest automotive manufacturers in the world, company leadership aims to produce 18 battery electric cars and fuel cell-powered vehicles by 2023. The company has already opened its market for EVs in China, where General Motors reported selling more cars than it did in the United States in 2017. In the summer of 2017, “it started selling a two-seat EV there, for just $5,300.” Pressure from regulators in China, Europe, and California to slash carbon emissions from fossil fuels is partially responsible for the shift in attitude at these major companies. Other influential forces include “Tesla Inc.’s success in creating electric sedans and SUVs that inspire would-be owners to line up outside showrooms and flood the company with orders.” Fiat-Chrysler claims to be “going after Tesla,” producing four electrified Maserati models by 2022.

______

______

Section-5

Energy sources and Electricity generation:

_

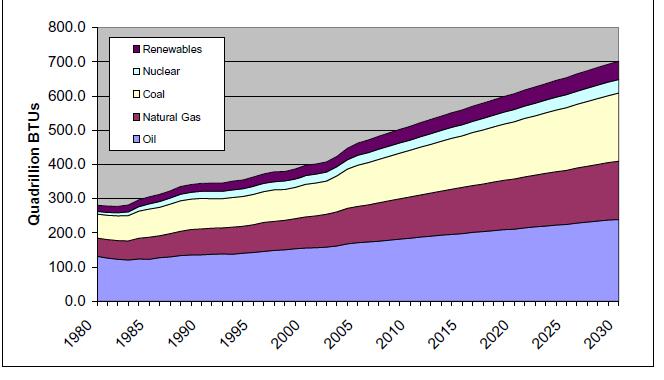

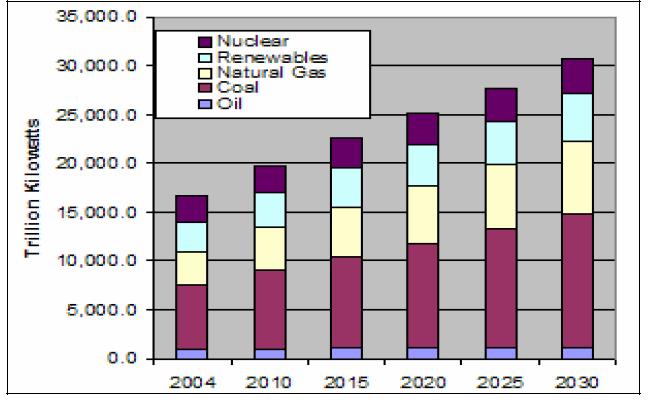

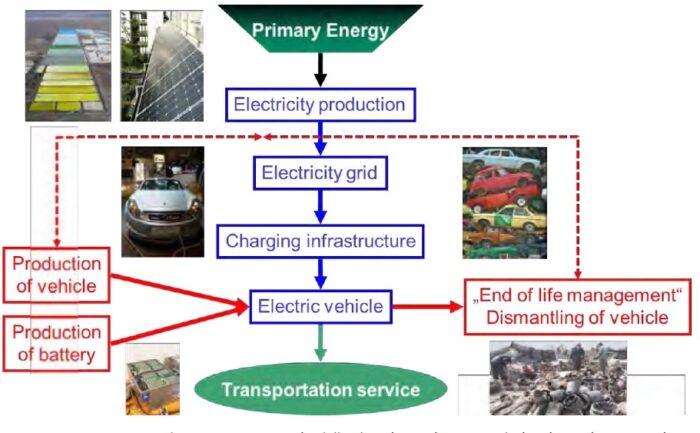

Figure below shows projected worldwide energy sources:

Worldwide energy production is projected to grow at an annual rate of over 2% providing for an expanding population and industrial development, despite increasing efficiencies in consumption. Figure above shows that fuels, primarily petroleum oil is projected to grow at a similar rate, even in scenarios where the fuel remains at relatively high historical costs. 2030 World oil consumption is accordingly projected at 210 quadrillion Btu (118 million barrels annually), an increase of over 30% compared to 2004. The portion of oil used for transportation is growing and is projected to use 68% of liquid fuel energy over the period 2004 – 2030. Significant concerns have been raised about the security of oil supply and initiatives have been outlined to diversify energy in transportation including initiatives proposed by the US Administration and the Department of Energy. These initiatives include the development of a vehicle that plugs-in and derives a great deal of its utility using energy from the electric power grid. Recent enthusiasm in PHEVs and E-REVs, in part, stems from these concerns.

_

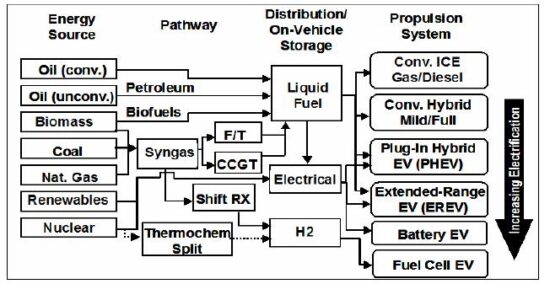

Figure below shows a network of the various energy sources, energy pathways, and possible on-vehicle energy storage media. Higher power motors, higher energy on-board electrical storage, and systems that allow for driving without a combustion engine enable vehicles that can use non-petroleum energy sources for transportation. Therefore increase in electrical content and magnitude onto the vehicle “electrification” is called for.

Figure above shows Energy sources, paths, on-vehicle storage and vehicle propulsion systems.

Diverse energy sources figure into the future of the world’s total energy bill. Yet today, automobiles rely almost exclusively on liquid fuels as the on-vehicle storage medium. Note that most other sources can be, and are already, used as part of the electric grid as shown figure below.

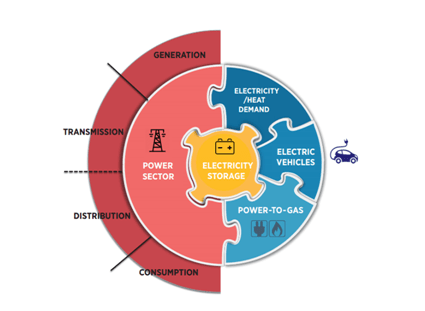

Electric grid power is a natural candidate for transportation energy distribution with on-vehicle storage. Worldwide grid electricity is expected to approximately double in the next two decades, outstripping the growth in total energy consumption. Improved generating efficiency from new plants means that electrical generation will continue to use approximately 40% of the world energy sources.

If electric energy can be effectively stored and integrated to propel automobiles, the full range of energy sources could be tapped for future automotive needs. Furthermore, future improvements in the efficiency and environmental impact of electric power generation will be directly realized by the PHEVs and E-REVs on the road at that time.

Figure above shows Projected worldwide electric power capacity

_

Electrification:

Several technical and commercial challenges are associated with charging, storing and making use of electric energy to propel automobiles. The term “electrification” means development and integration of systems and components that enable electric energy to be used for transportation. Challenges of electrification include providing automotive levels of reliability and durability, package density, acceptable noise, vibration and harshness, and automotive levels of cost in a set of new components and control algorithms.

There are three benefits to vehicle electrification: reduced petroleum consumption, reduced emissions, and energy diversification. Energy security comes from the ability to use multiple energy sources via electric pathways and on-vehicle storage, and a net reduction in fuel usage.

________

________

Section-6

History of electric vehicle:

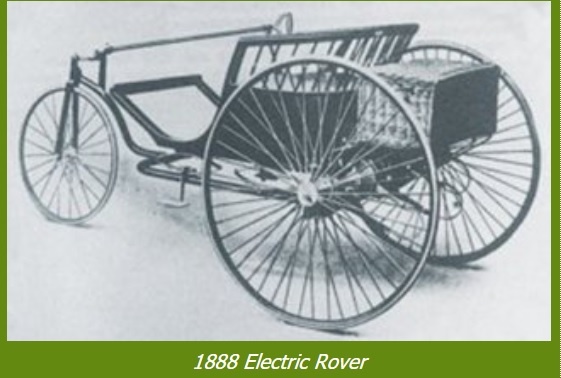

The first practical electric cars were produced in the 1880s. In November 1881, Gustave Trouvé presented an electric car at the Exposition internationale d’Électricité de Paris. In 1884, over 20 years before the Ford Model T, Thomas Parker built a practical production electric car in Wolverhampton using his own specially designed high-capacity rechargeable batteries. The Flocken Elektrowagen of 1888 was designed by German inventor Andreas Flocken and is regarded as the first real electric car.

Electric cars were among the preferred methods for automobile propulsion in the late 19th and early 20th century, providing a level of comfort and ease of operation that could not be achieved by the gasoline cars of the time. The electric vehicle stock peaked at approximately 30,000 vehicles at the turn of the 20th century.

In 1897, electric cars found their first commercial use as taxis in Britain and the US. In London, Walter Bersey’s electric cabs were the first self-propelled vehicles for hire at a time when cabs were horse-drawn. In New York City, a fleet of twelve hansom cabs and one brougham, based on the design of the Electrobat II, were part of a project funded in part by the Electric Storage Battery Company of Philadelphia. During the 20th century, the main manufacturers of electric vehicles in the US were Anthony Electric, Baker, Columbia, Anderson, Edison, Riker, Milburn, Bailey Electric, Detroit Electric and others. Unlike gasoline-powered vehicles, the electric ones were less noisy, and did not require gear changes.

Six electric cars held the land speed record in the 19th century. The last of them was the rocket-shaped La Jamais Contente, driven by Camille Jenatzy, which broke the 100 km/h (62 mph) speed barrier by reaching a top speed of 105.88 km/h (65.79 mph) on 29 April 1899.

Electric cars were popular until advances in internal combustion engine (ICE) cars (electric starters in particular) and mass production of cheaper petrol (gasoline) and diesel vehicles led to a decline. ICE cars’ much quicker refueling times and cheaper production costs made them more popular. However, a decisive moment was the introduction in 1912 of the electric starter motor that replaced other, often laborious, methods of starting the ICE, such as hand-cranking.

Despite waning popularity of electric cars, electric trains gained immense popularity due to their economies and fast speeds achievable. By the 20th century, electric rail transport became commonplace due to advances in the development of electric locomotives. Over time their general-purpose commercial use reduced to specialist roles, as platform trucks, forklift trucks, ambulances, tow tractors and urban delivery vehicles, such as the iconic British milk float; for most of the 20th century, the UK was the world’s largest user of electric road vehicles. Electrified trains were used for coal transport, as the motors did not use precious oxygen in the mines. Switzerland’s lack of natural fossil resources forced the rapid electrification of their rail network.

Starting in 2008, a renaissance in electric vehicle manufacturing occurred due to advances in batteries, and the desire to reduce greenhouse gas emissions and improve urban air quality.

_

Modern electric cars:

The emergence of metal-oxide-semiconductor (MOS) technology led to the development of modern electric road vehicles. The MOSFET (MOS field-effect transistor, or MOS transistor), invented by Mohamed M. Atalla and Dawon Kahng at Bell Labs in 1959, led to the development of the power MOSFET by Hitachi in 1969, and the single-chip microprocessor by Federico Faggin, Marcian Hoff, Masatoshi Shima and Stanley Mazor at Intel in 1971. The power MOSFET and the microcontroller, a type of single-chip microprocessor, led to significant advances in electric automobile technology. MOSFET power converters allowed operation at much higher switching frequencies, made it easier to drive, reduced power losses, and significantly reduced prices, while single-chip microcontrollers could manage all aspects of the drive control and had the capacity for battery management. Another important technology that enabled modern highway-capable electric cars is the lithium-ion battery, invented by John Goodenough, Rachid Yazami and Akira Yoshino in the 1980s, which was responsible for the development of electric cars capable of long-distance travel.

In the early 1990s, the California Air Resources Board (CARB) began a push for more fuel-efficient, lower-emissions vehicles, with the ultimate goal being a move to zero-emissions vehicles such as electric vehicles. In response, automakers developed electric models, including the Chrysler TEVan, Ford Ranger EV pickup truck, GM EV1, and S10 EV pickup, Honda EV Plus hatchback, Nissan Altra EV miniwagon, and Toyota RAV4 EV. Both US Electricar and Solectria produced 3-phase AC Geo-bodied electric cars with the support of GM, Hughes, and Delco. These early cars were eventually withdrawn from the U.S. market.

California electric automaker Tesla Motors began development in 2004 of what would become the Tesla Roadster, which was first delivered to customers in 2008. The Roadster was the first highway legal all-electric car to use lithium-ion battery cells, and the first production all-electric car to travel more than 320 km (200 miles) per charge. The Mitsubishi i-MiEV, launched in 2009 in Japan, was the first highway legal series production electric car, and also the first all-electric car to sell more than 10,000 units (including the models badged in Europe as Citroën C-Zero and Peugeot iOn) in February 2011 as officially registered by Guinness World Records. Several months later, the Nissan Leaf, launched in 2010, surpassed the i MiEV as the all-time best selling all-electric car.

In July 2019, US-based Motor Trend magazine awarded the fully electric Tesla Model S the title “ultimate car of the year”.

In January 2020, Nissan reported Leaf cumulative global sales totaling 450,000 units. In March 2020, the Tesla Model 3 became the world’s all-time best-selling electric car, with more than 500,000 units delivered.

In November 2020, GM announced it plans to spend more on electric car development over next 5 years than it spends on gas and diesel vehicles.

______

______

Section-7

Introduction to EV:

_

Mobility of persons and goods is a crucial component of the competitiveness of the economy; mobility is also an essential citizen right. Effective transportation systems are important for social prosperity, having significant impacts on economic growth, social development and the environment. The goal of any sustainable transport policy is to ensure that our transport systems meet society’s economic, social and environmental needs.

In 2006 the transport sector consumed 31% of the total final energy consumption (of which 82% is due to road transport) and was responsible for 25% of CO2 emissions (EU-27). In 2007 road transport constituted about 83% of passenger total transport demand. Road transport accounts for 71% of transport related CO2 emissions and passenger cars constitute 63% of these road transport related CO2 emissions. Currently, road transport is also totally dependent (>90%) on fuel oil making it very sensitive to foreseeable shortage of crude oil, besides largely contributing to air pollutants such as NOx, PM10 and volatile organic compounds.

It is estimated that more than 80% of the developed world population lives in an urban environment and therefore it is in this environment where a larger concentration of vehicles are found. As example there were about 230 million passenger vehicles in the EU-27 in 2007 and the new vehicle sales were nearly 16 million vehicles in that year. Consequently the urban population is very much at risk by directly suffering the impact of conventional vehicles because their closeness to the pollutant source. Air pollution is one of the important external costs of transport as it impacts on the health of the population (it is estimated to be 0.75% of the EU GDP). On the other hand, the large concentration of vehicles causes traffic congestions in metropolitan urban areas that can be considered a threat to economic competitiveness (a recent study on the subject showed that the external costs of road traffic congestion alone amount to about 1.25% of the EU GDP) and it also increases the inefficiency of an overcrowded transport infrastructure.

Electric vehicles (EV) might offer a step change technology based on the much higher efficiency of electric motors compared to ICEs as well as the potential to decarbonize the energy chain used in transportation and in particular in the well to tank pathway (JRC et al., 2008, Thiel et al., 2010). This will also open the possibility to use alternative energy paths to secure mobility and making the road transport more independent from crude oil.

_

An electric vehicle (EV), also referred to as an electric drive vehicle, is a vehicle which uses one or more electric motors for propulsion. An electric vehicle may be powered through a collector system by electricity from off-vehicle sources, or may be self-contained with a battery, solar panels, fuel cells or an electric generator to convert fuel to electricity. Depending on the type of vehicle, motion may be provided by wheels or propellers driven by rotary motors, or in the case of tracked vehicles, by linear motors. Electric vehicles can include electric cars, electric trains, electric trucks, electric lorries, electric airplanes, electric boats, electric motorcycles and scooters, and electric spacecraft.

EVs first came into existence in the mid-19th century, when electricity was among the preferred methods for motor vehicle propulsion, providing a level of comfort and ease of operation that could not be achieved by the gasoline cars of the time. Modern internal combustion engines have been the dominant propulsion method for motor vehicles for almost 100 years, but electric power has remained commonplace in other vehicle types, such as trains and smaller vehicles of all types.

Commonly, the term EV is used to refer to an electric car. In the 21st century, EVs have seen a resurgence due to technological developments, and an increased focus on renewable energy and the potential reduction of transportation’s impact on climate change and other environmental issues. Project Drawdown describes electric vehicles as one of the 100 best contemporary solutions for addressing climate change.

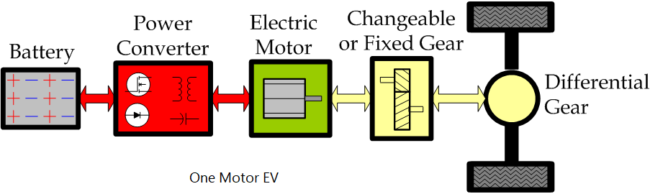

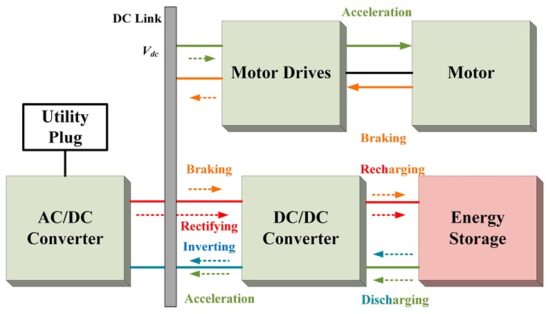

An electric car is an alternative fuel automobile that uses electric motors and motor controllers for propulsion, in place of more common propulsion methods such as the internal combustion engine (ICE). Electricity can be used as a transportation fuel to power battery electric vehicles (EVs). EVs store electricity in an energy storage device, such as a battery. The electricity powers the vehicle’s wheels via an electric motor. EVs have limited energy storage capacity, which must be replenished by plugging into an electrical source.

_

Electric vehicles are different from fossil fuel-powered vehicles in that they can receive their power from a wide range of sources, including fossil fuels, nuclear power, and renewable sources such as tidal power, solar power, and wind power or any combination of those. No matter how it is generated, this energy is then transmitted to the vehicle through use of overhead lines, wireless energy transfer such as inductive charging, or a direct connection through an electrical cable. The electricity may then be stored onboard the vehicle using a battery, flywheel, supercapacitor, or fuel cell. Vehicles making use of engines working on the principle of combustion can usually only derive their energy from a single or a few sources, usually non-renewable fossil fuels. A key advantage of electric or hybrid electric vehicles is their ability to recover braking energy as electricity to be restored to the on-board battery (regenerative braking) or sent back to the grid (V2G). At the beginning of the 21st century, increased concern over the environmental impact of the petroleum-based transportation infrastructure, along with the specter of peak oil, led to renewed interest in an electric transportation infrastructure. As such, vehicles which can potentially be powered by renewable energy sources, such as hybrid electric vehicles or pure electric vehicles, are becoming more popular.

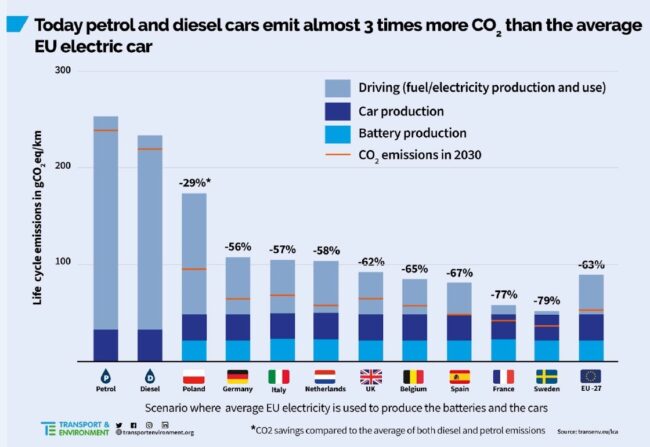

Electric cars have the potential of significantly reducing city pollution by having zero tail pipe emissions. Vehicle greenhouse gas savings depend on how the electricity is generated. With the U.S. energy mix using an electric car would result in a 30% reduction in carbon dioxide emissions. Given the current energy mixes in other countries, it has been predicted that such emissions would decrease by 40% in the UK, 19% in China, and as little as 1% in Germany.

Electric cars are commonly powered by on-board battery packs, and as such are battery electric vehicles (BEVs). Although electric cars often give good acceleration and have generally acceptable top speed, the poorer energy capacity of batteries compared to that of fossil fuels means that electric cars have relatively poor range between charges, and recharging can take significant lengths of time. However, for everyday use, rather than long journeys, electric cars are very practical forms of transportation and can be inexpensively recharged overnight. Other on-board energy storage methods that may give more range or faster recharge are areas of research.

Electric cars are expected to cause a revolution in the auto industry given advantages in city pollution, less dependence on foreign oil imports, and expected rise in gasoline prices.

_

Electric cars are a variety of electric vehicle (EV); the term “electric vehicle” refers to any vehicle that uses electric motors for propulsion, while “electric car” generally refers to road-going automobiles powered by electricity. While an electric car’s power source is not explicitly an on-board battery, electric cars with motors powered by other energy sources are generally referred to by a different name: an electric car powered by sunlight is a solar car, and an electric car powered by a gasoline generator is a form of hybrid car. Thus, an electric car that derives its power from an on-board battery pack is called a battery electric vehicle (BEV). Most often, the term “electric car” is used to refer to pure battery electric vehicles, such as the REVAi and GM EV1.

In an electric vehicle (EV), a battery or other energy storage device is used to store the electricity that powers the motor. EV batteries must be replenished by plugging in the vehicle to a power source. Some electric vehicles have onboard chargers; others plug into a charger located outside the vehicle. Both types, however, use electricity that comes from the power grid. Although electricity production may contribute to air pollution, EVs are considered zero-emission vehicles because their motors produce no exhaust or emissions.

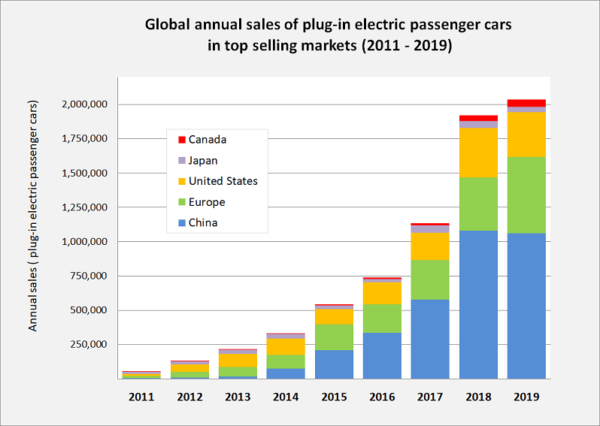

Government incentives to increase adoption were first introduced in the late-2000s, including in the United States and the European Union, leading to a growing market for the vehicles in the 2010s. And increasing consumer interest and awareness and structural incentives, such as those being built into the green recovery from the COVID-19 pandemic, is expected to greatly increase the electric vehicle market. A pre-COVID 2019 analysis, projected that Electric vehicles are expected to increase from 2% of global share in 2016 to 22% in 2030. Much of this market growth is expected in markets like North America and Europe; a 2020 literature review, suggested that growth in use of electric vehicles, especially electric personal vehicles, currently appears economically unlikely in developing economies.

____

Electric mobility:

Electric mobility, according to the definition of the German government and the National Development Plan for Electric Mobility (NEP) comprises all street vehicles that are powered by an electric motor and primarily get their energy from the power grid – in other words: can be recharged externally.

This includes purely electric vehicles, vehicles with a combination of electric motor and a small combustion engine (range extended electric vehicles – REEV) and hybrid vehicles that can be recharge via the power grid (plug-in hybrid electric vehicles – PHEV). Furthermore, the National Development Plan for Electric Mobility does not just look at specific vehicles but at the overall system. Aside from electric cars, this so-called systemic approach also includes the energy supply side as well as the charging and traffic infrastructure in its definition of electric mobility, since those components are interconnected and together, they lead to sustainable mobility. One thing all definitions have in common is the narrow interpretation of the term electric vehicles, which is based on the idea of electricity as “fuel.” This was chosen with good reason. Because when you consider the entire energy chain, only electricity offers efficiency advantages and – as long as it comes from renewable sources – a significant reduction of CO2-emissions.

____

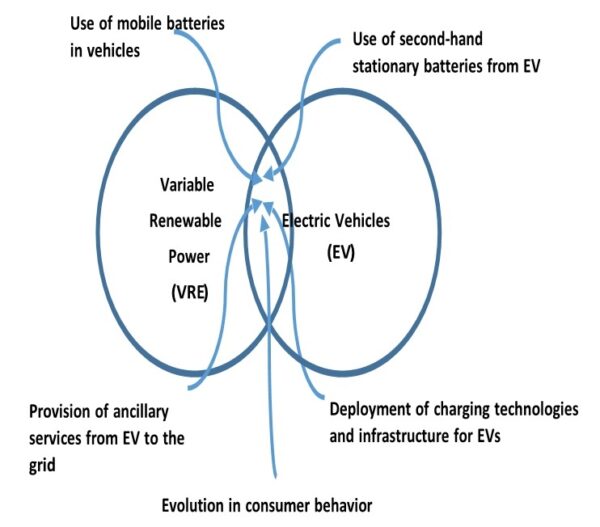

In recent times, electric vehicles (EV) are gaining popularity, and the reasons behind this are many. The most eminent one is their contribution in reducing greenhouse gas (GHG) emissions. In 2009, the transportation sector emitted 25% of the GHGs produced by energy related sectors. EVs, with enough penetration in the transportation sector, are expected to reduce that figure, but this is not the only reason bringing this century old and once dead concept back to life, this time as a commercially viable and available product. As a vehicle, an EV is quiet, easy to operate, and does not have the fuel costs associated with conventional vehicles. As an urban transport mode, it is highly useful. It does not use any stored energy or cause any emission while idling, is capable of frequent start-stop driving, provides the total torque from the startup, and does not require trips to the gas station. It does not contribute either to any of the smog making the city air highly polluted. The instant torque makes it highly preferable for motor sports. The quietness and low infrared signature makes it useful in military use as well. The power sector is going through a changing phase where renewable sources are gaining momentum. The next generation power grid, called ‘smart grid’ is also being developed. EVs are being considered a major contributor to this new power system comprised of renewable generating facilities and advanced grid systems. All these have led to a renewed interest and development in this mode of transport.

The idea to employ electric motors to drive a vehicle surfaced after the innovation of the motor itself. From 1897 to 1900, EVs became 28% of the total vehicles and were preferred over the internal combustion engine (ICE) ones. But the ICE types gained momentum afterwards, and with very low oil prices, they soon conquered the market, became much more mature and advanced, and EVs got lost into oblivion. A chance of resurrection appeared in the form of the EV1 concept from General Motors, which was launched in 1996, and quickly became very popular. Other leading carmakers, including Ford, Toyota, and Honda brought out their own EVs as well. Toyota’s highly successful Prius, the first commercial hybrid electric vehicle (HEV), was launched in Japan in 1997, with 18,000 units sold in the first year of production. Today, almost none of those twentieth century EVs exist; an exception can be Toyota Prius, still going strong in a better and evolved form. Now the market is dominated by Nissan Leaf, Chevrolet Volt, and Tesla Model S; whereas the Chinese market is in the grip of BYD Auto Co., Ltd (Xi’an National Hi-tech Industrial Development Zone, Xi’an, China).

___

EVs can be front wheel drive, rear wheel drive, even all-wheel drive. Different configurations are applied depending on the application of the vehicle. The motor can also be placed inside the wheel of the vehicle which offers distinct advantages. This configuration is not commercially abundant now, and has scopes for more study to turn it into a viable product.

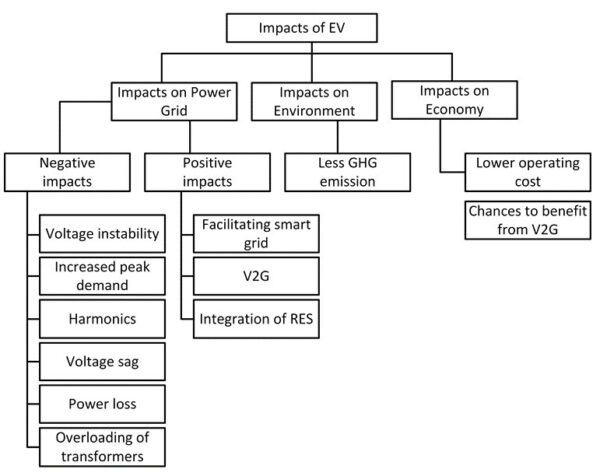

EV impacts the environment, power system, and economy alongside the transportation sector. It shows promises to reduce the GHG emissions as well as efficient and economical transport solutions. At the same time, it can cause serious problems in the power system including voltage instability, harmonics, and voltage sag, but these shortcomings may be short-lived if smart grid technologies are employed. There are prospects of research in the areas of V2G, smart metering, integration of Renewable Energy Systems, and system stability associated with EV penetration.

EVs employ different techniques to reduce energy loss and increase efficiency. Reducing the drag coefficient, weight reduction, regenerative braking, and intelligent energy management are some of these optimization techniques. Further research directions can be better aerodynamic body designs, new materials with less weight and desired strength, ways to generate and restore the lost energy.

Different control algorithms have been developed for driving assist, energy management, and charging. There is lots of room left for more research into charging and energy management algorithms. With increased EV penetration in the future, demands for efficient algorithms are bound to increase.

_

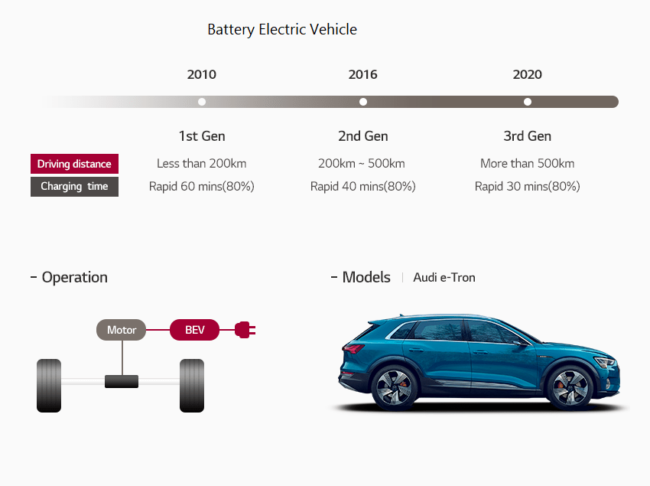

A battery electric vehicle (BEV), pure electric vehicle, only-electric vehicle or all-electric vehicle is a type of electric vehicle (EV) that exclusively uses chemical energy stored in rechargeable battery packs, with no secondary source of propulsion (e.g., hydrogen fuel cell, internal combustion engine, etc.). BEVs use electric motors and motor controllers instead of internal combustion engines (ICEs) for propulsion. They derive all power from battery packs and thus have no internal combustion engine, fuel cell, or fuel tank. BEVs include – but are not limited to – motorcycles, bicycles, scooters, skateboards, railcars, watercraft, forklifts, buses, trucks, and cars.

In 2016 there were 210 million electric bikes worldwide used daily. Cumulative global sales of highway-capable light-duty pure electric car vehicles passed the one million unit milestone in September 2016. As of October 2020, the world’s top selling highway legal all-electric car in history is the Tesla Model 3, with an estimated 645,000 sales, followed by the Nissan Leaf with over 500,000 sales as of September 2020.

_

How does an Electric Car work in general?

When pedal of the car is pressed, then:

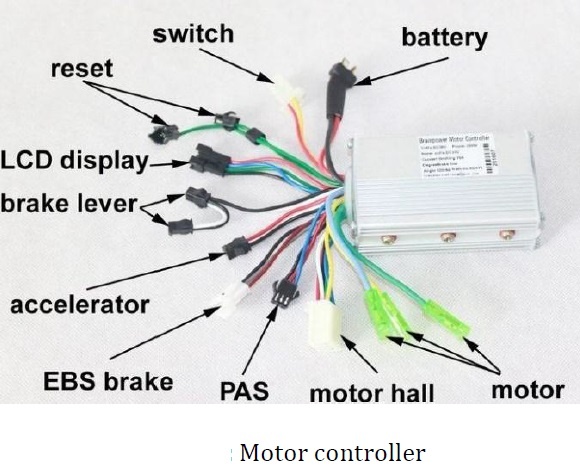

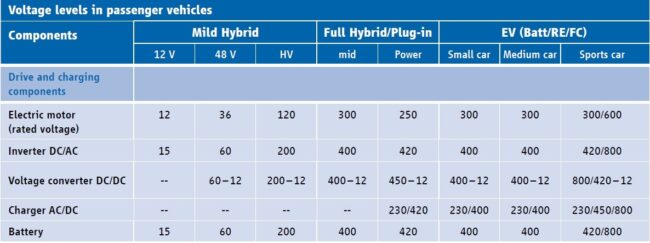

-1. Controller takes and regulates electrical energy from batteries and inverters

-2. With the controller set, the inverter then sends a certain amount of electrical energy to the motor (according to the depth of pressure on the pedal)

-3. Electric motor converts electrical energy into mechanical energy (rotation)

-4. Rotation of the motor rotor rotates the transmission so the wheels turn and then the car moves.

Note: The working principle above is for battery electric vehicle (BEV) type

_______

Are electric cars automatic?

Most electric cars are automatic, and likely will be in the future. This is because an electric car doesn’t require a clutch due to its inability to stall like a petrol or diesel vehicle. Therefore, adding a clutch and various gears might not make much sense. However, some companies have been trying to produce electric vehicles that do still have a five- or six-speed gearbox, to maintain some form of normality for drivers who are used to manual vehicles.

When you drive a manual vehicle and you come to a complete stop, you must use both the clutch pedal and the brakes to prevent stalling the engine. However electric engines cannot stall in the same way, so clutch isn’t needed.

Electric car also doesn’t require gears. Electric vehicles don’t feature a multi-speed gearbox like conventional petrol or diesel vehicles. Instead, they have just one gear. In a combustion engine, the engine generates torque, which is used for acceleration, and power in a narrow band of engine speeds, or gears. In order to accelerate, the rpm must be kept relatively high to gain the necessary torque and power that’s required. The gears allow you to keep the power between a set amount so that you can gradually speed up and slow down while still having enough torque to do so. First gear can only get you up to a certain speed before the amount of rpm becomes too much and you need to move up to second gear. In contrast, electric motors generate 100 per cent of their torque at very low speeds (under 1,000 rpm). The more the rpms increase, the less torque is generated therefore it’s actually more beneficial to stick to a low rpm of around 2,000. It doesn’t mean that electric cars can’t have gears, but they aren’t necessary to make the car run.

Not only are electric cars missing a clutch and various gears, but the braking system is different too. Regenerative brakes are used where an electric motor functions as an electric generator to slow car & recharge batteries.

_