Dr Rajiv Desai

An Educational Blog

Desalination

Desalination:

_

The history of water is equivalent to the history of the world and the history of water quality is equivalent to the history of life.

—Andreas N. Angelakis

_

Section-1

Prologue:

All early civilizations were built on the banks of rivers. Whether it was the Euphrates in the Fertile Crescent or the Tiber in Rome, rivers gave early settlements easy access to abundant streams of fresh water, essential not only for drinking but also for irrigating crops. The availability of water was one of the biggest constraints on the growth of settlement and population size. The layout of Ancient Egypt reflected this. It stretched out like a long snake, hugging the banks of the Nile River. The invention of aqueducts by the Romans first enabled water to be carried long distances, providing the crucial utility to remote stretches of its sprawling empire and allowing populations to settle far from fixed sources of water. The Roman method of diverting freshwater to new habitations is still the essential means modern cities use to provide water to their residents. Water is life, and without water, there would be no civilizations and a vacant Earth. Water is considered an abundant natural resource on the earth. Water covers about 70% of the planet, but only 2.5% of that water is fresh, and only about half of that fresh water is accessible. This small portion of the available water supplies the needs of humans and animals. However, freshwater that exists in underground, rivers, and lakes is insufficient to cover all the world’s water demands. Few, if any, countries have the luxury of unlimited water resources. For many countries, water resources are becoming increasingly limited in both quantity and quality. Human water consumption has increased beyond sustainable levels in many regions, resulting in depletion of natural water sources, and lower quality water in drinking water reservoirs, including groundwater systems. Thus, water saving, water reuse, rainwater harvesting, stormwater utilization, and desalination are critical for maintaining water supplies for the future of humanity.

_

I was brought up and educated in Mumbai. Mumbai water supply solely depends on rainfall. Every year we used to look up in the sky for adequate rainfall to prevent water shortage. We were at the mercy of nature. Nobody thought of desalination plant for Mumbai in those days although Mumbai is a coastal city. I was serving as medical specialist in the Red Sea coastal town of Umm Laaj in the northern Tabuk region of Saudi Arabia between 2001 to 2006. The entire town was supplied with desalinated seawater. I used desalinated water daily from 2001 to 2006. I was wondering why my hometown Mumbai has no desalination plant. The Brihanmumbai Municipal Corporation (BMC) supplies 3,900 million litres of water daily (MLD) to the city. However, the city’s reliance on its seven lakes for potable water causes anxiety every year as lake levels recede. So, to augment water supply, the BMC has initiated the ambitious project of a desalination plant. The plant will be of a capacity of 200 MLD that can be expanded to 400 MLD at a later stage and will be set up in Manori, Malad. It is expected to be completed in the next four years.

_

Oceans cover 70 per cent of the planet. They provide nourishment for over three billion people and absorb 30 per cent of carbon dioxide released into the atmosphere and 90 per cent of the heat from climate change. Increasingly, they are also providing freshwater for a burgeoning population. Did you know that several countries, such as the Maldives, Malta and the Bahamas, meet all their water needs through the desalination process—that is, they convert seawater to freshwater? Scientists have known that the Earth’s natural hydrologic cycle continuously desalinates water, using solar energy as the water evaporates from the oceans and lakes, leaving behind the salt and mineral content. The resulting freshwater vapors form clouds which produce rain and snow. This hydrological cycle continuously moves salt from land to the oceans. The rain that falls on the land contains some dissolved carbon dioxide from the surrounding air. This causes the rainwater to be slightly acidic due to carbonic acid. The rain physically erodes the rock and the acids chemically break down the rocks and carries salts and minerals along in a dissolved state as ions. The ions in the runoff are carried to the streams and rivers and then to the ocean. Oceans are salty because when water evaporates, the salts remain and accumulate.

_

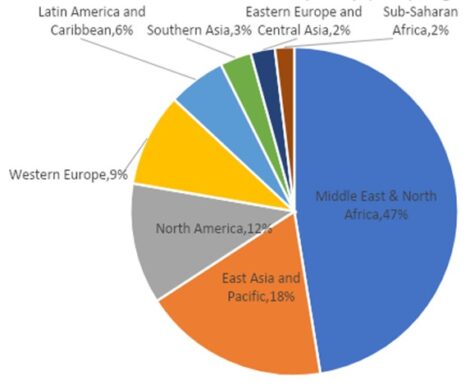

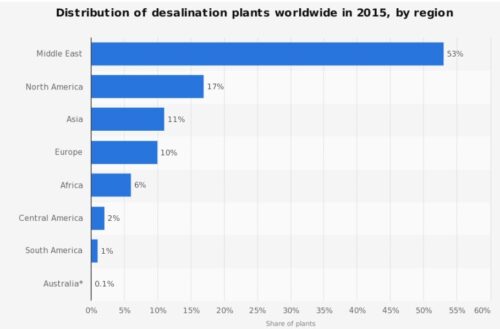

Desalination is simply the process of removing salt from water. Or, sometimes, removing the water from the salt. While this may sound simple, it is a problem that scientists have been trying to efficiently solve for decades. Considering that 25% of the world’s population does not have access to properly sanitized water, there is a major incentive to develop cheap, sustainable desalination technologies. Moreover, 40% of the world’s population lives within 60 miles of the coast. This means that there is a ready supply of water for much of the human population if only the salt can be removed. Presently about 500 million people depend on desalination (desal) as their primary source of water every day. Large number of countries around the world, and especially in the MENA (the Middle East and North Africa) region, suffer from extreme levels of water scarcity throughout the year. MENA region embraces around 47.5 % of the world’s desalination capacity.

_

In its most recent annual risk-assessment report, the World Economic Forum lists water crisis as the most significant potential global risk driven by water stress, increasing world population, improving living standards, changing consumption patterns, and expansion of irrigated agriculture because of rainfall shortage and increasing food consumption. Currently, 4 billion people are under water stress at least one month per year, and 33 countries are expected to experience extremely high water stress by 2040. Water is critical for sustainable development, environmental integrity and the eradication of poverty and hunger. Inaccessibility of clean water sources negatively impacts health, ability to work and the economy. Water facilities must be available for use at a price that is affordable to economically challenged people. Many regions of the world are facing formidable freshwater scarcity. Although there is substantial scope for economizing on the consumption of water without affecting its service level, the main response to water scarcity has been to increase the supply. To a large extent, this is done by transporting water from places where it is abundant to places where it is scarce. At a smaller scale and without a lot of public and political attention, people have started to tap into the sheer limitless resource of desalinated water. As demand for water is going to rise exponentially and water supply will continue to be scarce and even more erratic, desalination of sea water appears to be only mode for ensuring water security of the nation.

_

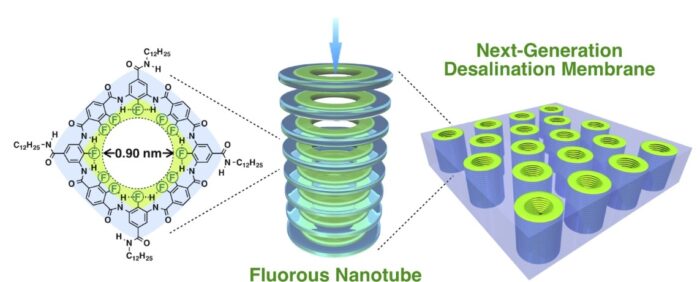

Most of the desalination plants in the Middle East were based on the evaporation and condensation technology. But in addition to evaporation, Americans were working on another type of technology that would turn out to have the most promise for the future: membranes. Essentially, the water was pushed through a series of barriers with openings of a size and shape that only water molecules could pass through, leaving behind most salt and other impurities. By the 1980s membranes had become the standard technology used in many of the world’s desalination plants. Today further advancements in nanotechnology are making the membranes smaller and more effective at filtering out unwanted particles, and distillation plants are now in the minority. Israel, Saudi Arabia, the United Arab Emirates, and Australia now obtain a significant percentage of their water from ocean-fed plants that push water through membranes. Kuwait and Qatar are entirely dependent on desalinated water for both domestic and industrial uses and spend billions of dollars each year to keep it flowing.

_

Currently, desalinated water only provides about 1% of the world’s drinking water, but the International Water Association expects production capacity to double by 2030. It may need to grow even faster to keep up with climate change. A paper published by the American Meteorological Society predicted that the total percentage of Earth’s land in extreme drought at any given time will have grown from 1% in 2006 to 30% by the end of the 21st century. As climate change redistributes water around the planet, causing wet places to become wetter and dry places to become drier, more and more people are going to be dependent on alternate water sources. Even the United States, where droughts have again increased during the past two decades, has begun reinvesting in desalination. A number of membrane plants have come online in Texas and California since 2005, and others are planned for Los Angeles and Corpus Christi.

_

Beyond the energy consumption and expense, desalination has another major downside: it produces extra-salty brine that sinks to the sea floor where it kills marine life. Additionally, such plants would have enormous carbon footprints. Critics of desalination argue that it’s wasteful to spend money and energy on desalinating seawater (even if the plants are powered by solar panels) when humans dump billions of gallons of wastewater into lakes and rivers every day. Why not recycle the leftover water from showers and toilets and send it back into the system instead of wasting energy desalting ocean water? Part of the reason some governments have been resistant to recycling water is because the concept sounds a little gross; detractors call it “toilet to tap.” On the other hand, around the world there are at least 1.2 billion people living in areas that don’t have water to recycle to begin with. For those people the only options appear to be desalination. With climate change causing more frequent droughts, desalination offers a potential solution to sustain growing populations in the most arid regions of the planet. Given that the raw water source in desalination is virtually inexhaustible, it offers a drought-free solution for municipalities and industries, ensuring water security. One more factor that works out in favour of the proposal is that the cost of desalinated water has been decreasing over the years, thanks to technological advancements. My endeavour is to study whether desalination is sustainable and affordable alternative water source or not.

______

______

Abbreviations and synonyms:

Desalination = Desal = Desalinization = Desalinisation

CAPEX = Capital Expenditures

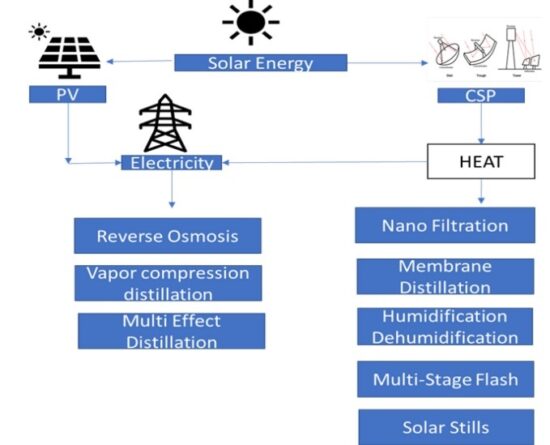

CSP = Concentrated Solar Power

GCC = Gulf Cooperation Council

GHG = Greenhouse Gas

MD = Membrane Desalination

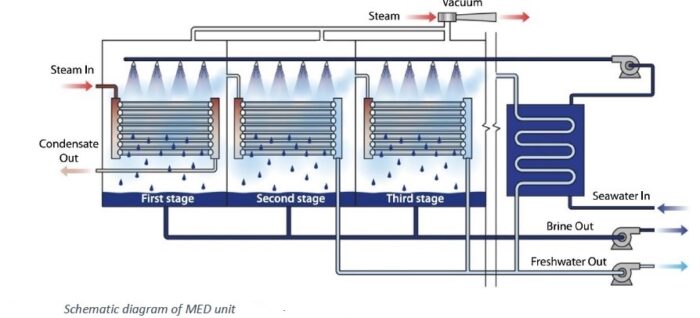

MED = Multi-Effect Distillation = Multi-Effect Evaporation = MEE

MENA = Middle East and North Africa

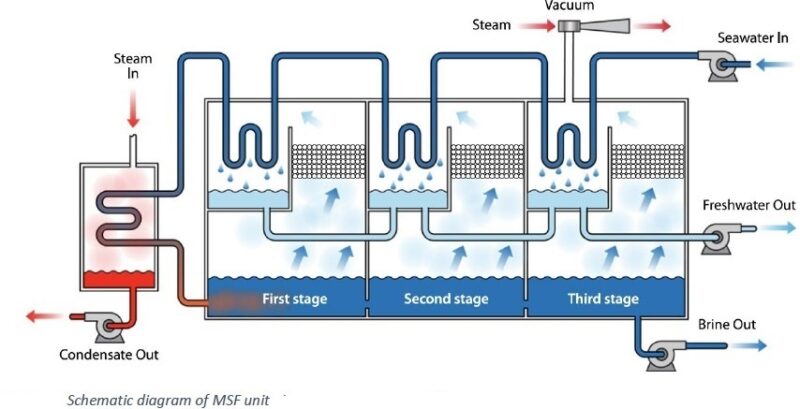

MSF = Multi-Stage Flash

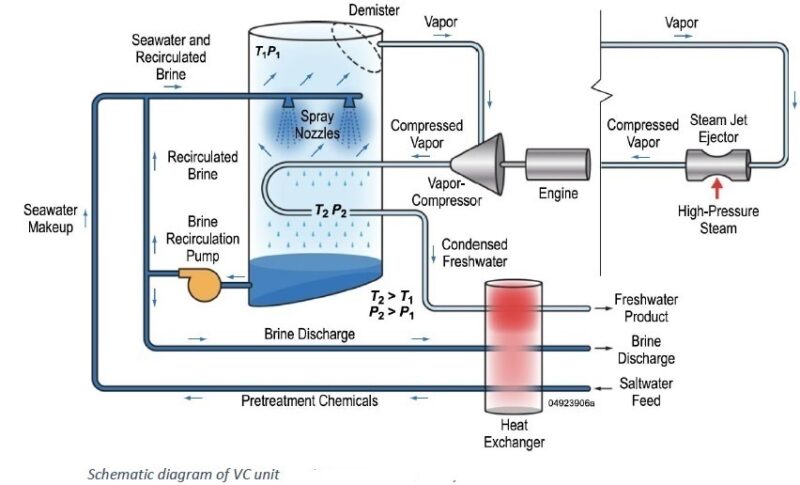

MVC = Mechanical Vapour Compression

OPEX = Operating Expenditures

PV = Photovoltaic

SW = seawater

BW = blackish water

WW = waste water

RW = river water

RO = Reverse Osmosis

TDS = Total Dissolved Salts

VCD = Vapour Compression Distillation

VC = vapor-compression

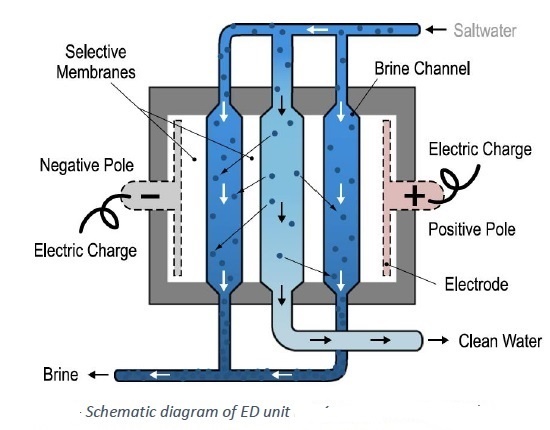

ED = electro-dialysis

NF = nanofiltration

MF = microfiltration

UF = ultrafiltration

FO = forward osmosis

EDR = electro-dialysis reversal

TVC = thermal vapor-compression

π = osmotic pressure

c = molar solute concentration

R = gas constant

T = absolute temperature

VMD = vacuum MD

SWRO = seawater reverse osmosis

SEC = specific energy consumption

GO = graphene oxide

GOR = gained output ratio

RR = recovery ratio

ERD = energy recovery devices

BWRO = brackish water reverse osmosis

CDI = capacitive deionization

CNT = carbon nanotube

ZLD = zero liquid discharge

TBT = top brine temperature

LCA = life-cycle assessment

HPRO = high-pressure reverse osmosis

MLD = million liters per day

MGD = million gallons per day

MCM = million cubic meters

One cubic meter (m3) = 1000 liters ≈ 264 gallons

One acre foot = 1233.48 cubic meters (m3)

______

______

Section-2

Water characteristics and standards:

By definition, drinking water should have a salt content of no more than 0.01 per cent. The term ‘fresh water’ is used for a salt content of up to 0.05 per cent, while most crops can tolerate a salt content of up to 0.2 per cent. Water covers about 71% of the Earth’s surface. Over 96.5% of the Earth’s water supply remains in seas and oceans but, because of its saltiness, is not suitable for drinking. Just 2.5% of all the water on the planet is fresh, which means it could be directly used by humans and animals. Out of total fresh water, 70 per cent isn’t accessible – trapped, for instance, in polar ice. What remains is less than one per cent. Half of the world’s groundwater is either too contaminated with other substances or too saline to be suitable for drinking without treatment. This so-called brackish water has a salt content of between 0.05 and three per cent. For all of these different types of water, the same basic formula applies: the higher the percentage of salt, the more difficult, damaging and energy consuming becomes the process of desalination – at least for those technologies currently in use in significant enough numbers.

_

Salinity:

Salinity is the saltiness or amount of salt dissolved in a body of water. Salinity is expressed in the unit g/kg, which is often written as ppt (part per thousand) or ‰. Note that % means grams per deciliter and ‰ means grams per kilogram.

|

Fresh water |

Brackish water |

Saline water |

Brine |

|

< 0.05% |

0.05 – 3% |

3 – 5% |

> 5% |

|

< 0.5 ‰ |

0.5 – 30 ‰ |

30 – 50 ‰ |

> 50 ‰ |

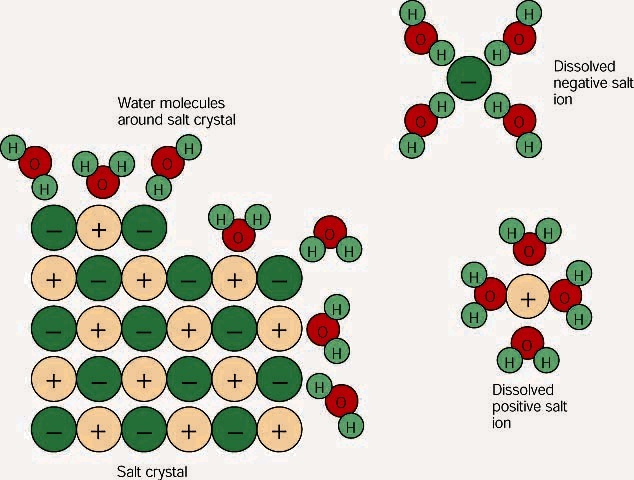

Sodium is a mineral and it is one of the chemical elements that are found in salt. Our bodies need a certain amount of sodium to function. However, too much sodium can be harmful. People cannot drink saline water, but saline water can be turned into freshwater in a process called desalination.

_

Salinity in rivers, lakes, and the ocean is conceptually simple, but technically challenging to define and measure precisely. Conceptually the salinity is the quantity of dissolved salt content of the water. Salts are compounds like sodium chloride, magnesium sulfate, potassium nitrate, and sodium bicarbonate which dissolve into ions. The concentration of dissolved chloride ions is sometimes referred to as chlorinity. Operationally, dissolved matter is defined as that which can pass through a very fine filter (historically a filter with a pore size of 0.45 μm, but nowadays usually 0.2 μm). Salinity can be expressed in the form of a mass fraction, i.e. the mass of the dissolved material in a unit mass of solution.

Seawater typically has a mass salinity of around 35 g/kg, although lower values are typical near coasts where rivers enter the ocean. Rivers and lakes can have a wide range of salinities, from less than 0.01 g/kg to a few g/kg, although there are many places where higher salinities are found. The Dead Sea has a salinity of more than 200 g/kg. Precipitation typically has a TDS of 20 mg/kg or less.

_

Seawater, or sea water, is water from a sea or ocean. On average, seawater in the world’s oceans has a salinity of about 3.5% (35 g/L, 35 ppt, 600 mM). This means that every kilogram (roughly one liter by volume) of seawater has approximately 35 grams (1.2 oz) of dissolved salts (predominantly sodium (Na+) and chloride (Cl−) ions). The average density at the surface is 1.025 kg/L. Seawater is denser than both fresh water and pure water (density 1.0 kg/L at 4 °C (39 °F)) because the dissolved salts increase the mass by a larger proportion than the volume. The freezing point of seawater decreases as salt concentration increases. At typical salinity, it freezes at about −2 °C (28 °F). The coldest seawater still in the liquid state ever recorded was found in 2010, in a stream under an Antarctic glacier: the measured temperature was −2.6 °C (27.3 °F). Seawater pH is typically limited to a range between 7.5 and 8.4. Most natural freshwaters have pH values in the range from 6.5 to 8.0. Most waters have some capacity to resist pH change through the effects of the carbonate-buffer system.

_

TDS vs salinity:

The key difference between TDS and salinity is that TDS is the measurement of all types of solid compounds in a given liquid sample whereas salinity is the measurement of the amount of salt that is dissolved in a given liquid sample. Often, people use the terms TDS and salinity interchangeably though they are two different terms. The term TDS stands for total dissolved solids while salinity refers to the dissolved salt amount in water.

______

______

TDS:

TDS is total dissolved solids. It is a measure of the dissolved combined content of all inorganic and organic substances in a liquid. Common inorganic salts that can be found in water include calcium, magnesium, potassium and sodium, which are all cations, and carbonates, nitrates, bicarbonates, chlorides and sulfates, which are all anions. Cations are positively charged ions and anions are negatively charged ions. The unit of measurement of this TDS parameter is usually “part per million (ppm)”. For water, 1 ppm = approximately 1 mg/L of contaminant in water. We can easily determine the TDS level of water using a digital meter. The most important application of TDS parameter is the study of water quality for streams, rivers, and lakes. There are several different primary sources of TDS including,

-1. Agricultural runoff

-2. Residential runoff

-3. Clay-rich mountain waters

-4. Leaching of soil contamination

-5. Point source water pollution from industrial sites

-6. Sewage treatment plants

The form of dissolved chemical substances in liquids with a high TDS level can be cations, anions, molecules or agglomerates. The toxic chemical components that can cause harmful health effects due to high TDS levels in water are pesticides that arise from surface runoff. Some naturally occurring total dissolved solids come from the weathering and dissolution of rocks and soils.

_

Why should you measure total dissolved solids?

Total dissolved solids can affect your water quality, your health, your home plumbing system, and even daily tasks, such as cooking and cleaning. By measuring your water for TDS, you can better understand your water quality and how it affects your everyday life, allowing you to make an informed decision to solve your water quality problem and install the most effective filtration system for your home.

-1. Taste and smell

Tap water with a high concentration of total dissolved solids (TDS) can have a bitter taste and unpleasant smell. The higher the concentration of total dissolved solids, the more bitter your water will be.

-2. Health

High TDS water is not necessarily unhealthy to drink, but certain substances, such as lead and copper, are health hazards. For example, lead exposure can cause brain and nervous system damage and high levels of copper exposure can cause nausea.

-3. Filter maintenance

Water filtration systems are a great solution to reduce total dissolved solids but are subject to normal wear and tear. Routine testing for TDS can provide assurance that your filter system is working properly and can alert you when maintenance is required.

-4. Plumbing and appliances

Water that contains high levels of dissolved calcium and magnesium is hard water and can result in high TDS levels. When calcium and magnesium salts dissolve, they collect in pipes and form scale buildup, which results in costly pipe replacements and shortens the lives of your appliances.

-5. Cooking

Though not detrimental to your health at levels below 1000 ppm, cooking with elevated TDS water can change the taste of food. For example, if your water has high levels of chlorine, you may find that your pasta absorbs an unpleasant taste from the boiling water.

-6. Cleaning

If your dishes have water spots no matter how well you clean them, your clothes fade in the wash, and you have buildup in your sinks, your cleaning woes may be caused by high levels of total dissolved solids.

_

Taste of Water with Different TDS:

In a study by the World Health Organization, a panel of tasters came to the following conclusions about the preferable level of TDS in water:

TDS Level in parts per million(ppm) Palatability Quotient:

|

TDS in Water (measured in PPM) |

Suitability for Drinking Water |

|

Between 50-150 |

Excellent for drinking |

|

150-250 |

Good |

|

250-300 |

Fair |

|

300-500 |

Poor, not good for drinking |

|

Above 1200 |

Unacceptable |

A very low concentration of TDS has been found to give water a flat taste, which is undesirable to many people. Generally, the TDS level between 50-150 is considered as the most suitable and acceptable. If the TDS level is about 1000 PPM, it is unsafe and unfit for human consumption.

_

According to the Bureau of Indian Standards (BIS), the upper limit of TDS levels in water is 500 ppm. The TDS level recommended by WHO, however, is 300 ppm. The World Health Organization (WHO) sets out guidelines for drinking water quality that include the recommendation that water with TDS below 300 PPM is considered safe for drinking. However, most authorities accept 500 PPM. In the United States, the average is 350 PPM of TDS in standard drinking water from the tap. It’s important to note that with measurements being predicted in parts per million, it’s going to take some sophisticated equipment to catch every substance. Usually, total dissolved solids are tested using a TDS meter which uses electricity to determine the conductivity of the water and uses that data to determine TDS level results.

_

Three of the most common ways to reduce TDS in water are:

-1. Reverse Osmosis (RO): TDS is lowered through Reverse Osmosis by pushing the water using pressure through an artificial membrane. The membrane has tiny holes that allow only particles smaller than 0.0001 microns to go through. Since the particles of dissolved metals and salts are bigger than water molecules, only water goes through the membrane, leaving the metals and salts behind.

-2. Distillation: This method involves boiling water to create water vapor. The vapor goes up to a cool surface and changes back into liquid. The dissolved salts can’t turn into vapor and stay in the boiling water.

-3. Deionization (DI): Deionization is a chemical process for removing minerals from water by extracting ions, or electrically charged particles, from the water supply.

All three methods are advanced and unless you have an RO water filter at home, there is not much you can do to reduce the TDS of the water. It is recommended that you at least boil the water properly before consuming it, as it kills most of the bacteria and viruses present in the water. Boiling water removes hard water causing bicarbonates of magnesium and calcium, as well as nasty contaminants in the main supply, such as chlorine and lead. Once boiled and cooled, you can pour the remaining water into another container, ensuring it retains its purity and softness.

Does boiling salt water get rid of the salt?

No. Boiling it will make it saltier as the water will start to evaporate leaving the salt behind in less water. You can boil fresh water for drinking purpose and not salty water.

_

TDS versus hardness:

Hardness measures the presence of calcium and magnesium salts in forms like bicarbonates, chlorides, and sulfates, while TDS includes all minerals, not just calcium and magnesium. When measuring water treated with water softeners, high levels of total dissolved solids do not correlate to hard water, as water softeners do not reduce TDS; rather, they replace magnesium and calcium ions, which cause hard water, with an equal charge of sodium or potassium ions, e.g. Ca2+ ⇌ 2 Na+, leaving overall TDS unchanged or even increased.

Hard water leaves deposits and films on fixtures, and on the insides of hot water pipes and boilers. Soaps and detergents do not produce as much lather with hard water as with soft water. Hard water can cause scale buildup in pipes, valves, and filters, reducing performance and adding to system maintenance costs. These effects can be seen in aquariums, spas, swimming pools, and reverse osmosis water treatment systems.

_

Desalination and TDS:

Desalination is a general term for the process of removing salt from water to produce fresh water. Fresh water is defined as containing less than 1000 mg/L of salts or total dissolved solids (TDS) (Sandia, 2003). Above 1000 mg/L, properties such as taste, color, corrosion propensity, and odor can be adversely affected. Many countries have adopted national drinking water standards for specific contaminants, as well as for TDS, but the standard limits vary from country to country or from region to region within the same country. Most desalination facilities are designed to achieve a TDS of 500 mg/L or less. Desalinated water used for other purposes, such as crop irrigation, may have a higher TDS concentration; irrigation water standards often include concentration limits for TDS, chloride, sodium, and boron. Depending on the type of crop, the chloride standard can range from 350 mg/L to more than 2000 mg/L.

The feed water salinity for desalination facilities ranges from approximately 1000 mg/L TDS to 60,000 mg/L TDS, although feed waters are typically labeled as one of two types: seawater or brackish water. Although most seawater sources contain 30,000–45,000 mg/L TDS, seawater reverse osmosis membranes are used to treat waters within the TDS range 10,000 – 60,000 mg/L. Brackish water reverse osmosis membranes are used to treat water sources (often groundwater sources) within a range of 1000–10,000 mg/L TDS. The feed water type can dictate several design choices for a treatment plant, including desalination method, pretreatment steps, waste disposal method, and product recovery (the fraction of influent water that becomes product).

_____

_____

Causes of saltiness of water:

-1. From precipitation to the land to the rivers to the sea….

The rain that falls on the land contains some dissolved carbon dioxide from the surrounding air. This causes the rainwater to be slightly acidic due to carbonic acid. The rain physically erodes the rock and the acids chemically break down the rocks and carries salts and minerals along in a dissolved state as ions. The source of the salts in water is the surrounding rocks, e.g. the mineralogy of the aquifer. Therefore, surface water is usually less salty than groundwater, which is surrounded by rocks. The ions in the runoff are carried to the streams and rivers and then to the ocean. Many of the dissolved ions are used by organisms in the ocean and are removed from the water. Others are not used up and are left for long periods of time where their concentrations increase over time.

-2. The second source is actually from the ocean itself. Gashes in the seafloor, called hydrothermal vents, produce large amounts of steam and heat. This causes a variety of chemical reactions. Among these reactions is the release of metal ions into the water, like sodium, chloride, and magnesium.

-3. Oceans are salty because when water evaporates, the salts remain and accumulate.

_

The two ions that are present most often in seawater are chloride and sodium. These two make up over 90% of all dissolved ions in seawater. The concentration of salt in seawater (its salinity) is about 35 parts per thousand; in other words, about 3.5% of the weight of seawater comes from the dissolved salts. In a cubic mile of seawater, the weight of the salt (as sodium chloride) would be about 120 million tons. A cubic mile of seawater can also contain up to 25 pounds of gold and up to 45 pounds of silver! But before you go out and try alchemy on seawater, just think about how big a cubic mile is: 1 cubic mile contains 1,101,117,147,000 gallons of water!

_

Near the equator, the tropics receive the most rain on a consistent basis. As a result, the fresh rain water falling into the ocean decreases the salinity of the surface water in that region. Rain decreases further from the equator, and with less rain and more sunshine, evaporation increases. Evaporation of water vapor from the ocean to the atmosphere leaves behind the salt, resulting in higher salinity. Toward the poles, fresh water from melting ice decreases the surface salinity once again. The saltiest locations in the ocean are the regions where evaporation is highest or in large bodies of water where there is no outlet into the ocean. The saltiest ocean water is in the Red Sea and in the Persian Gulf region (around 40ppt) due to very high evaporation and little fresh water inflow.

_____

Sea water intrusion:

Seawater intrusion is among the primary groundwater contamination processes in coastal areas, where saline water is moving moves towards or mixing with freshwater aquifers. When the extreme freshwater abstraction from a coastal aquifer surpasses the natural recharge of freshwater from surface water, salty water is drawn into the aquifer. Thus, seawater intrusion is a major issue in many continents, such as European, north, and south Mediterranean coastal areas. Seawater intrusion has also become an essential issue in North Africa and Middle East, the USA, and Turkey. Several research studies on seawater intrusion in coastal areas have been conducted. These studies showed that the mismanagement of the coastal aquifers resulted in an uncontrolled saltwater intrusion. All these results indicate that many coastal areas have been affected by seawater intrusion processes.

_____

_____

If saltwater is still water, why can’t we drink it?

Accidentally consuming small quantities of clean seawater is not harmful, especially if the seawater is taken along with a larger quantity of fresh water. However, drinking seawater to maintain hydration is counterproductive; more water must be excreted to eliminate the salt (via urine) than the amount of water obtained from the seawater itself. In normal circumstances, it would be considered ill-advised to consume large amounts of unfiltered seawater.

Seawater contains salt. When humans drink seawater, their cells are thus taking in water and salt. While humans can safely ingest small amounts of salt, the salt content in seawater is much higher than what can be processed by the human body. Additionally, when we consume salt as part of our daily diets, we also drink liquids, which help to dilute the salt and keep it at a healthy level. Living cells do depend on sodium chloride (salt) to maintain the body’s chemical balances and reactions; however, too much sodium can be deadly.

Human kidneys can only make urine that is less salty than salt water. Therefore, to get rid of all the excess salt taken in by drinking seawater, you have to urinate more water than you drank. Eventually, you die of dehydration even as you become thirstier.

Survival manuals consistently advise against drinking seawater. A summary of 163 life raft voyages estimated the risk of death at 39% for those who drank seawater, compared to 3% for those who did not. The effect of seawater intake on rats confirmed the negative effects of drinking seawater when dehydrated.

_

Some animals can drink saltwater, so why can’t we?

Some animals, in ocean ecosystems have adaptations that allow them to safely drink saltwater. Seabirds such as albatrosses, gulls and penguins, which might spend weeks on the open ocean with no freshwater in sight, have specialized salt glands and grooves in their bills for filtering and purging excess salt from ingested water before it hits their stomachs and is absorbed into their blood. Marine mammals such as whales, dolphins and seals have also evolved adaptations to life in an environment where freshwater is scarce or absent. Marine mammals have adapted special enzymes and cellular structures that allow them to purge excess salt from their systems. It’s like they have super kidneys.

_

Since humans and a fair portion of the planet’s plant and animal population can’t subsist on saltwater, people have long looked enviously at the sea to provide the water they require, whether it’s for drinking, hygiene, agriculture or more recently, industrial purposes. Historically, desalination was deemed too expensive to be considered a viable large-scale option; it simply required too much energy. But newer technologies, such as reverse osmosis and multistage flash distillation, have, since the 1950s, slowly started to change that opinion, especially in places where sources of freshwater are scarce, and people are plentiful.

______

______

Difference between desalination and demineralization:

Desalination and demineralization are both processes used to purify water, but they differ in their source, purpose, process, technology, and applications. Desalination is used to remove salt and other minerals from seawater to make it drinkable, while demineralization is used to remove minerals and impurities from freshwater for various purposes. Desalination is used to purify seawater, while demineralization is used to purify freshwater. Desalination often uses reverse osmosis or distillation, while demineralization often uses ion exchange or other chemical treatments.

The demineralisation process produces high-quality water – without removing the minerals, the water could interfere with and contaminate the various industrial processes that demineralised water is used for, including:

Laboratory testing

Analytical chemistry

Cleaning lab equipment

Coolant systems

______

Differences between desalination and water treatment systems:

-1. Different purposes:

The purpose of a seawater desalination system is to convert saltwater (mainly seawater) into fresh water. This is a widely used technology in areas with relatively scarce freshwater resources, especially near the ocean. The main principle is to remove salt from seawater through methods such as reverse osmosis and distillation, and produce fresh water suitable for human consumption and industrial use.

The purpose of a water treatment system is to improve the quality of existing water sources. This may include removing pollutants, heavy metals, bacteria, etc. from natural water sources to ensure that the water meets specific water quality standards. Water treatment systems are mainly used in water treatment plants, industrial wastewater treatment plants, etc., to provide clean water sources for various purposes.

-2. Source of raw water:

The raw water of seawater desalination systems mainly comes from high salinity water bodies such as oceans and saltwater lakes. These water sources themselves cannot be directly used by humans and require desalination treatment.

The raw water of the water treatment system can include tap water, river water, lake water, etc., with relatively low salinity. The water treatment system mainly deals with various pollutants and impurities in natural water sources.

-3. Process principle:

The core processes of seawater desalination systems include technologies such as reverse osmosis and multi-stage distillation. Reverse osmosis removes salt through a semi-permeable membrane, while distillation evaporates and re-condenses water through heating and cooling, achieving salt separation.

The process of water treatment system involves various technologies, such as filtration, sedimentation, disinfection, etc., to remove pollutants from water. These processes vary depending on the water source and are typically purified through various methods such as physical, chemical, and biological methods.

______

Differences between RO water and distilled water:

- Reverse osmosis water and distilled water are very similar because they’re both pure water sources.

- The main difference between reverse osmosis water and distilled water is the method of purification: RO water is produced by membrane separation, while distilled water is made by evaporation and condensation.

- RO water may contain some volatile organic compounds (VOCs) and chemicals, and distilled water may contain some chemicals and heavy metals.

_______

_______

Section-3

Water scarcity:

_

World water:

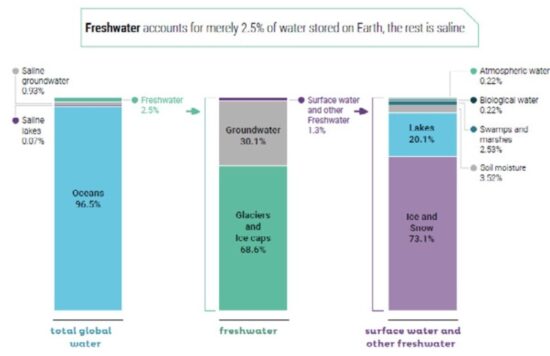

About 71 percent of the Earth’s surface is water-covered, and the oceans hold about 96.5 percent of all Earth’s water. Water also exists in the air as water vapor, in rivers and lakes, in icecaps and glaciers, in the ground as soil moisture and in aquifers, and even in humans and animals. Figure below shows how almost all of Earth’s water is saline and is found in the oceans. Of the small amount that is actually freshwater, only a relatively small portion is available to sustain human, plant, and animal life.

_

Major Stocks of Water on Earth

|

Location |

Amount (106 km3) |

Percentage of World Water |

|

Ocean |

1338.0 |

96.5 |

|

Glaciers and permanent snow |

24.1 |

1.74 |

|

Groundwater (brackish or saline) |

12.9 |

0.94 |

|

Groundwater (fresh) |

10.5 |

0.76 |

|

Ground ice/permafrost |

0.30 |

0.022 |

|

Freshwater lakes |

0.091 |

0.007 |

|

Freshwater stream channels |

0.002 |

0.0002 |

The average annual rainfall over land amounts to 119000 km3, of which some 74000 km3 evaporate back into the atmosphere. The remaining 45000 km3 flow into lakes, reservoirs and streams or infiltrate into the ground to replenish the aquifers. This represents what is conventionally called “water resources”. Not all of these 45000 km3 are accessible for use because part of the water flows into remote rivers and during seasonal floods. An estimated 9000 – 14000 km3 are all that are economically available for human use, a teaspoon in a full bathtub compared to the total amount of water on earth.

_

As noted in Table above, nearly 1 percent of the world’s water exists as brackish or saline groundwater. In most inland cases, groundwater salinity results from the dissolution of minerals present in the subsurface, possibly concentrated further by evapotranspiration. Coastal aquifers form another class of brackish water, which is created from the natural mixing of seawater with groundwater that is discharging to the ocean. The thickness of this brackish mixing zone is sometimes increased by coastal groundwater pumping. Brackish groundwater exists at elevations less than 305 m (1,000 feet) across much of the conterminous United States (Feth, 1965) and almost certainly at comparable depths in Hawaii and Alaska. Both coastal and inland communities are increasingly considering brackish groundwater as a possible water supply resource.

_

The distribution of freshwater around the world is not uniform. In this case, unbalanced distribution caused that some parts of the groundwater resources have become greatly available to several specific areas with low population and convenient access to freshwater such as the northern parts of Russia, Scandinavia, Canada, Alaska and southern parts of South America. Additionally, areas with a high population or areas with industrial growth are more vulnerable to water stress and areas that are in arid regions also have a degree of water stress based on the ratio of water consumption to the amount of available water. Obviously considering the significance of upstream water use on downstream stress has a direct effect on water distribution (Munia et al. 2016). The index of water stress is essentially linked to per capita water use.

______

______

Daily water consumption per capita:

Demands for freshwater in developed countries are increasing. For example, the daily consumption per person in the USA is 400 L. Some developed countries with the help of restrictions and regulations have reduced the consumption of water up to 150 L. However, the studies indicated that with the difficulty of access to freshwater resources in some areas around the world, a low amount of water would be consumed. For example, the consumption per person in Africa is 20 L per day. The World Health Organization (WHO) considers that consuming 15–20 L per day is necessary for human survival. On the other hand, for some uses, such as hospitals and schools, consumption of 50 L per person per day is essential.

_

The average water consumption per capita in Saudi Arabia is 270 l/day for municipal purposes according to the Water Statistics Report in GCC Countries of 2018. It means that for 1 million citizens we need to build water desalination plant of capacity 270000 m3/day. We considered only water demand for municipal purposes of one million people, but what if we include also the industrial and agricultural water demand. Obviously, the water consumption would be much more than in a previous case. It comes to 2460 l/day. Knowing the total amount of water that is required for one person per capita for agricultural, industrial and municipal purposes, we could calculate the capacity of desalination plant.

_____

_____

Water scarcity in the world:

Water is very essential for life. It is one of the most abundant resources of the earth, covering about 3/4th of earth’s surface. Though it covers earth’s major portion yet there is severe shortage of potable water in many countries around the world mainly in developing countries and middle east region countries. The reason for this situation is that nearly 97.5% of earth’s water is salt water and remaining 2.5% is fresh water which is in the form of ground water, ice-mountains, lakes and rivers, which serves most human and animal needs. For every 20 years, the consumption rate of water is doubling exceeding by two times the rate of population growth. The potable water resources are on the decline and water demand is high. In recent times various industrial and developmental activities have resulted in increasing pollution and deteriorating the quality of water. Thus, water shortages and unreliable quality of water are considered to be major hindrances for sustainable development of society.

_

Water is a vital source of life on earth, particularly for Human Life. Around 785 million people have no access to clean water, and 144 million people fulfil their needs from surface water. Water vulnerability is affecting 1.42 billion people in the world. Only 2.5% of water is fresh in the World, and this water is becoming scarce due to mismanagement, misuse, contamination, and over-extraction. Urbanization, population growth, and industrialization have increased the water demands in the world. Climate change also contributes to water scarcity as extreme weather conditions like floods, droughts, change in precipitations, and sea-level rise contaminate freshwater resources, destroy water and sewage infrastructure, and reduce available water. Water-related disasters occurred about 74% from 2001 to 2018, destroying water and sanitation infrastructure. These disasters’ frequency will increase due to climate change. On the other hand, global water demand will increase about 20−30% by 2050 because of population growth, high living standards, and food and energy demand.

_

According to UNEP (United Nations Environment Programme) 1/3rd of the world’s population lives in countries with insufficient freshwater resources. Hence enormous efforts are required to make new water resources available and minimize water deficiency in countries with shortage of fresh water. World Health Organization guidelines state that the permissible limits of salinity in drinking water are 500 ppm and in few cases, it may extend up to 1000 ppm. Most of the water on earth has salinity ranging up to 10,000 ppm and for sea water it may be in the range of 35,000–45,000 ppm due to its dissolved salts.

_

The existing water resources are decreasing

- Due to unbalanced distribution of rain water and drought

- Extreme exploitation of ground water resources and its un sufficient recharge

- Degradation of water quality due to the discharge of domestic and industrial wastes without sufficient treatment

_

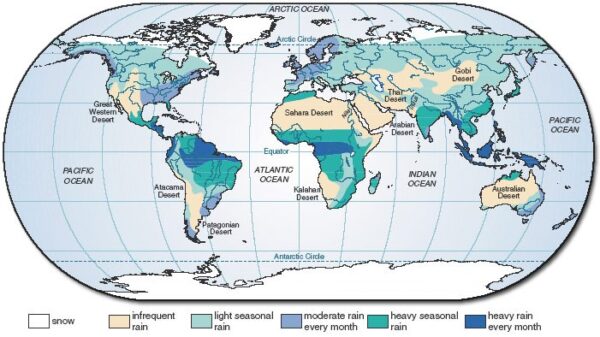

Figure below shows the global distributions of rainfall across the globe highlighting the regions that have water access and the regions that lack it.

Since the fresh water resources are very limited to serve the major population needs and salt water is unsuitable for many applications, desalination of salt water (sea water) emerges as a boon to most of the population to serve their needs.

_

Water can be scarce for many reasons: demand for water may be exceeding supply, water infrastructure may be inadequate, or institutions may be failing to balance everyone’s needs. Water scarcity is an increasing problem on every continent, with poorer communities most badly affected. To build resilience against climate change and to serve a growing population, an integrated and inclusive approach must be taken to managing this finite resource. Population growth, increasing consumption per capita and climate changes are three main stressors in the water resources. The World Water Program (WWP) estimates that by 2030 only 60% of the water needed will be available, and the Organization for Economic Co-operation and Development (OECD) has predicted that by 2050 this amount will reach 55%. By the end of the century, 40% of the world’s population will live in areas with water stress (Caldera et al. 2016). Overall, water demands will be doubled every 20 years (Eltawil et al. 2009; Kalogirou 2005). About 70% of the freshwater needed is for the agriculture section, 20% for the industry sector and only 10% for houses uses (El-Dessouky and Ettouney 2002). High rates of population growth and climate change have highlighted the need for new freshwater resources. Shortages of water resources are leading to a decline in the standard of living and economic growth.

_

The term ‘water shortage’ is defined by the UN as a situation in which there isn’t sufficient access to drinking water to fulfil human needs. The World Health Organisation (WHO) states that in times of crisis, every person needs guaranteed access to at least 15 litres of water per day – preferably all drinking water; at least fresh water. According to the World Water Institute, almost two billion people in 17 countries are heading straight for an acute water crisis in the coming years. This will lead to between 24 and 700 million people being displaced by as early as 2040, the UN has warned. ‘Water is among the top five global risks in terms of impacts, reaching far beyond socio-economic and environmental challenges and impacting livelihoods and well-being of the people,’ says Manzoor Qadir, an environmental scientist who focuses on water recycling and safe reuse at the United Nations University in Hamilton, Canada. In a recent study, Qadir and his colleagues concluded that ‘statistics demonstrate that “conventional” sources of water such as rainfall, snow-melt and river runoff captured in lakes, rivers and aquifers are no longer sufficient to meet human demands in water-scarce areas’. Qadir is calling for more desalination plants. ‘Desalination can extend water supplies beyond what is available from the hydrological cycle, providing an “unlimited”, climate-independent and steady supply of potable water,’ he says.

_____

Facts and Figures of water scarcity:

- 2.3 billion people live in water-stressed countries, of which 733 million live in high and critically water-stressed countries. (UN-Water, 2021)

- 3.2 billion people live in agricultural areas with high to very high water shortages or scarcity, of whom 1.2 billion people – roughly one-sixth of the world’s population – live in severely water-constrained agricultural areas. (FAO, 2020)

- Today, 1.42 billion people – including 450 million children – live in areas of high or extremely high water vulnerability. (UNICEF, 2021)

- About 4 billion people, representing nearly two-thirds of the global population, experience severe water scarcity during at least one month of the year. (Mekonnen and Hoekstra, 2016)

- 72% of all water withdrawals are used by agriculture, 16% by municipalities for households and services, and 12% by industries. (UN-Water, 2021)

- When a territory withdraws 25% or more of its renewable freshwater resources it is said to be ‘water-stressed’. Five out of 11 regions have water stress values above 25%, including two regions with high water stress and one with extreme water stress. (UN-Water, 2021)

____

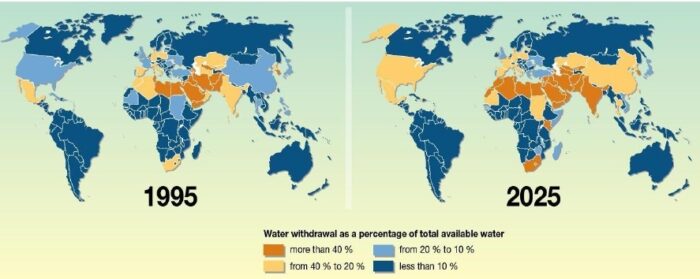

Forecast of water scarcity in 2025 is depicted in figure below:

The figure above shows how water related issue were in 1995 and the forecast of how worse could it be in 2025. According to this source, the world will face severe water shortages. The countries that have water withdrawal as a percentage of total available water from 10% to 20% would become even more water stressed reaching to numbers from 20% to 40%. The situation would be even more rough with the countries that already were water stressed. As climate change makes rainfall less predictable and droughts more common, a growing number of countries are turning to desalination. The term is used to refer to removing salt from both seawater and subterranean “brackish” water, as well as the treatment of waste water (aka sewerage) to make it drinkable.

_

Water scarcity is described as a condition where water demand exceeds over available water supply. A country or a region faces “water scarcity” when the availability of natural hygienic water falls below 1000 m3 per person per year (Pereira et al., 2002; Dehghani et al., 2019). Water scarcity is something that is not a concern with only a single living being at a particular location and time, but it affects a larger population within a certain geographic region (e.g., country) and pertains to larger timescales (years or months). It can occur because of natural low water availability as well as human-imposed activities to degrade the available natural water. The natural water body has the potential to renew or restore its originality. However, water pollution is the dominant factor to aggravates water scarcity by degrading the quality of water resources. The detrimental effect caused by nature and human intervention has led to severe water challenges and water scarcity, which is elaborated in the upcoming section.

_

Water scarcity arises in situations where there is insufficient water to simultaneously support both human and ecosystem water needs (White, 2014). Most often this arises as a result of a basic lack of water (i.e., physical water scarcity), but it may also result from a lack of suitable infrastructure to provide access to what might otherwise be considered ample available water resources, which is referred to as economic water scarcity. Physical water scarcity may occur as a result of both natural phenomena (e.g., aridity, drought) as well as from human influences (e.g., desertification, water storage; Pereira et al., 2009; White, 2014), although these influences are often coupled. For example, the process of desertification often commences as a result of water overuse during periods of temporary drought; droughts are more common in arid regions (McMahon et al., 1992). A key distinction between these various processes is in degree of permanency and reversibility. In the case of drought and water overuse, for example, the impacts may be temporary; however, those arising from aridity and desertification are more likely to be irreversible (Water, 2006). As Pereira et al. (2009) point out, this distinction is often confused when discussing water scarcity and its impacts, but it may be important in understanding both impacts and mitigation options.

_

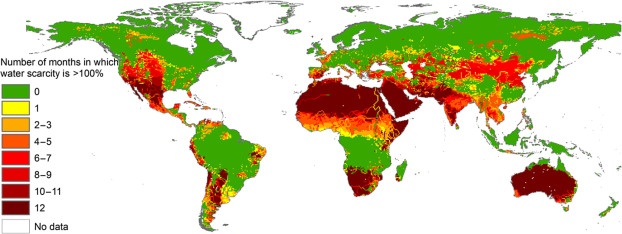

Map below shows the global distribution of regions affected by water scarcity.

_

Regardless of the cause, water scarcity impacts both human populations and natural ecosystems on all continents (Figure above). For example, recent estimates suggest approximately 4 billion people live under conditions of water scarcity for at least one month each year, with roughly 0.5 billion people exposed to severe water scarcity all year round (Mekonnen and Hoekstra, 2016). These figures nearly double previous estimates, in part by considering the flows required to remain in rivers to sustain flow-dependent ecosystems, as well as the goods and services they provide for people. In most, though not all regions, climate change is forecast to exacerbate water scarcity even further (Gosling and Arnell, 2016). These assessments highlight the massive global impacts of water scarcity on human livelihoods and on natural systems, and many global programs such as those of the United Nations focus on improved human access to water within a more sustainable ecosystem footprint.

_

Drought:

A drought is a period of dry weather that can extend for weeks, months, or years. It results in a shortage of water sources, including ground and rainwater. During a drought, plants begin to die from the lack of rain. If it lasts for several months, a drought can cause food shortages due to a decrease in crops. Droughts also negatively impact land and wildlife. At least 23 countries, including India, declared drought emergencies at a national or sub-national level during 2022-23, showed new data from a global drought map compiled by the United Nations, pointing to unprecedented urgency on a planetary scale. And the U.N. has warned that 130 more countries could face droughts by 2100 if we do nothing to curb climate change. But as soon as 2025, two-thirds of the global population could face water shortages, according to the World Wildlife Fund. This could result in conflicts, political instability, and the displacement of millions of people.

__

There are several different methods to measure water scarcity. One of these methods is the Falkenmark Indication, which looks at the number of people in an area and the volume of available water. According to this method, a volume of 1700m3/cap/year of available renewable freshwater per person means that the given area is experiencing water scarcity. A value of 1000m3/cap/year demonstrates high water scarcity, and 500m3/cap/year demonstrates absolute scarcity. The water use to availability ratio can also be used, where the available renewable water resources and amount of water used are looked at. The measure of water stress is the ratio of total water use (domestic, industrial or agricultural) to produced renewable water, including runoff in rivers and underground sources with little depth. With these different standards to determine water scarcity, there are also two different types of water scarcity, physical and economic. Physical water scarcity is associated with limited access to water resources, with the Middle East and North Africa (MENA) region, southeast Europe, Western Australia, and India being areas experiencing physical water scarcity. Economic water scarcity is the inability to have access to available water resources due to institutional, political influences, or other contributing factors. Central and Latin America, South and Central Africa and Asia regions demonstrate economic water scarcity.

__

The scarcity of fresh water may also make it harder to decarbonize society—something we must do to prevent catastrophic climate change—because some strategies to do this could further stress water resources. Green hydrogen, seen as key to eliminating emissions from aviation, shipping, trucking, and heavy industry, is produced by electrolysis, which splits water into hydrogen and oxygen. However, the process requires large amounts of purified water. One estimate is that nine tons of it are needed to produce one ton of hydrogen, but actually the treatment process used to purify the water requires twice as much impure water. In other words, 18 tons of water are really needed to produce one ton of green hydrogen. Nuclear energy, seen by the IPCC as an important tool for achieving our climate goals, also depends on fresh water for cooling, but as water shortages increase, nuclear plants may be forced to reduce their capacity or shut down.

_

As a result of water scarcity, some parts of the world have turned to desalination for drinking water. Desalination (desal) involves removing salt and minerals from salty water, usually seawater. This process occurs naturally as the sun heats the ocean—fresh water evaporates off the surface and then falls as rain. Arid regions like the Middle East and North Africa have long depended on desal technology for their fresh water. Today over 120 countries have desal plants with Saudi Arabia producing more fresh water through desal than any other nation. The United States also has a number of desal plants with the largest in the western hemisphere located in Carlsbad, CA. A new $1.4 billion desal plant in Huntington Beach, CA is likely to be approved soon.

_____

_____

Desalination as a solution to water scarcity:

Rapid population growth and urbanization are two main drivers for the over-abstraction of conventional freshwater resources in various parts of the world, which leads to the situation of water scarcity (per capita availability <1000 m3/year). The general trend showed that most of the water-scarce countries withdraw freshwater mainly for agricultural activities, municipal use, and industrial use. The highest use was in agriculture, which ranged from 0.02 to 9.13 m3/cap/day, with an average of 1.19 m3/cap/day. The average water withdrawal for municipal purposes was 0.140 m3/cap/day, which is eight times lower than for the agricultural sector. Predictions based on the World Bank projected population data and the FAO AQUASTAT database for freshwater availability show that by 2050, 2 billion people living in 44 countries will likely suffer from water scarcity, of which 95% may live in developing countries. Among these, the countries that will likely be most strongly hit by water scarcity by 2050 are Uganda, Burundi, Nigeria, Somalia, Malawi, Eritrea, Ethiopia, Haiti, Tanzania, Niger, Zimbabwe, Afghanistan, Sudan, and Pakistan. Currently, these countries have not yet established desalination to meet their freshwater demand. However, the current global trend shows that membrane-based desalination technology is finding new outlets for supplying water to meet growing water demand in most of the water-scarce countries. These 14 water-scarce countries will demand an additional desalination capacity of 54 Mm3/day by 2050 in order to meet the standard of current municipal water demand and to compensate for the withdrawal of renewable resources. Case studies from India, China, and South Africa have highlighted that other countries may apply the strategy of using desalinated water for industrial users.

_

The potential technical solutions to solve water scarcity are:

|

Saving water |

Increasing productivity in agriculture and industry |

|

Reducing leakages in public water supply |

|

|

Imposing progressive tariffs |

|

|

Increasing rainwater harvesting |

|

|

Water transport |

Transporting from long distances |

|

Aquifer storage |

Storing river water during high flow |

|

Water reuse |

Increasing reuse/recycling in industry |

|

and domestic wastewater in agriculture |

|

|

Desalination |

Using brackish water, wastewater, seawater |

_

Alternative water sources:

Traditionally, our water supply comes from surface water (rivers and lakes) and from groundwater. But increasingly, we are looking to other sources for our water – referred to collectively as ‘alternative water sources’.

These include:

- Recycled Water: Water from a municipal wastewater plant that has been treated to the point that it can be safely used again.

- Desalinated Water: Water from the ground or surface (e.g., brackish water or seawater) that has had the excess salts removed from it for use.

- Stormwater/rainwater: Water from runoff from precipitation events that is captured and sometimes treated for use.

- Greywater: Wastewater from households or office buildings that does not contain human waste and that is diverted and sometimes treated for reuse for landscapes and for flushing toilets.

Diversification of water supply portfolio – using non-traditional water sources – improves our water supply reliability and our ability to withstand drought conditions. Alternative water sources are crucial to that effort.

_

Among the different alternative solutions for solving the issues of water scarcity, desalination is only implemented as a last resort when conventional freshwater resources have been stretched to the limit. Desalination is considered as a drought-proof water source, since it does not depend on river flows, reservoir levels, or climate change. Desalination may be an option to alleviate scarcity in industry and for coastal cities. The report published by the United Nations showed that approximately 44% of the global population, and 8 out of the 10 largest metropolitan areas in the world, are located within a distance of 150 km from the coastline. The rate of population growth in the coastal regions is accelerating, and increasing tourism adds to the pressure on the environment (UN Atlas of the Ocean, 2017). Therefore, the possibility for widespread application of seawater desalination in the future is very likely. Although the most well-known application of desalination (and related membrane technology) is to produce freshwater from seawater, it can also be used to treat slightly saline (brackish) water, low-grade surface and groundwater, and treated effluent resources. The current global trend shows that desalination technology is finding new outlets as an alternative source for supplying water to meet growing water demands in most of the water-scarce countries. However, there have been barriers to the widespread adoption of this technology, mainly due to its cost, energy requirements, a lack of expertise, and its carbon footprint.

_

Why desalinate?

Three principal reasons for desalination:

-1. Creating a new standalone water source – Sweet-water shortages existing presently and expected in the future can be filled by the production of high-quality water, at reasonable cost, from the unlimited water source that is the sea.

-2. Water quality – The quality of water produced by desalination plants stands up to the most rigid quality control demands required of drinking water by WHO standards. The water is significantly softer, so that it precipitates significantly less scale and reduces the energy spent on water heating by the industrial and private sectors. Another advantage is receiving waste water with much less salinity than currently, making improved agricultural crops possible increasing the possibilities for use of wastewater, no less significantly, improving the groundwater.

-3. Economic benefit – Thanks to technological improvements and marketplace competition, desalination costs are dropping and production is becoming better and more efficient. Although desalinated water is more expensive than natural sweet water, the extra cost is insignificant when compared against the economic damage from dried-out agricultural land and parks. The drop in desalination cost is reflected in the tenders which were published over the years. In the Sorek B tender, the water price was set at approximately 1.5 NIS (0.4 $) per cubic meter.

_

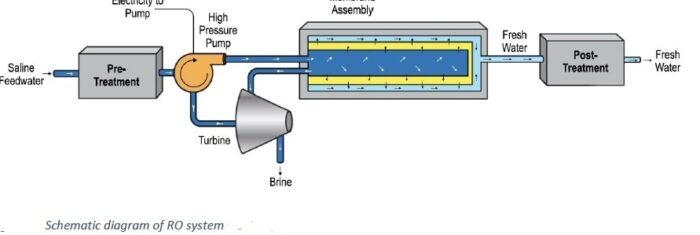

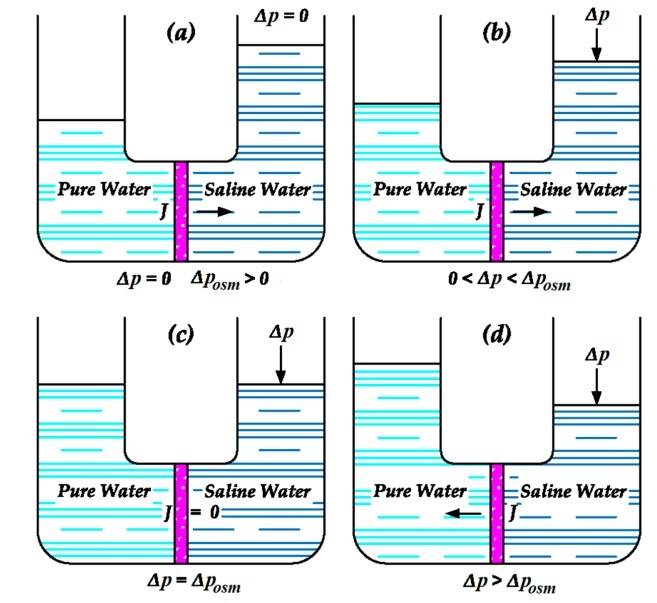

How does desalination work?

These are the two chief methods:

-1. Evaporation processes (the older technology) – The water gradually evaporates as it passes through a series of chambers that vary in temperature and pressure. In each chamber a certain quantity of water evaporates, and the salts remain in the water that has not evaporated. The salty water (about half the incoming water) is dumped back into the sea as brine. The water vapor passes through a condensation stage in which the drops of water are collected, and the product is desalinated water.

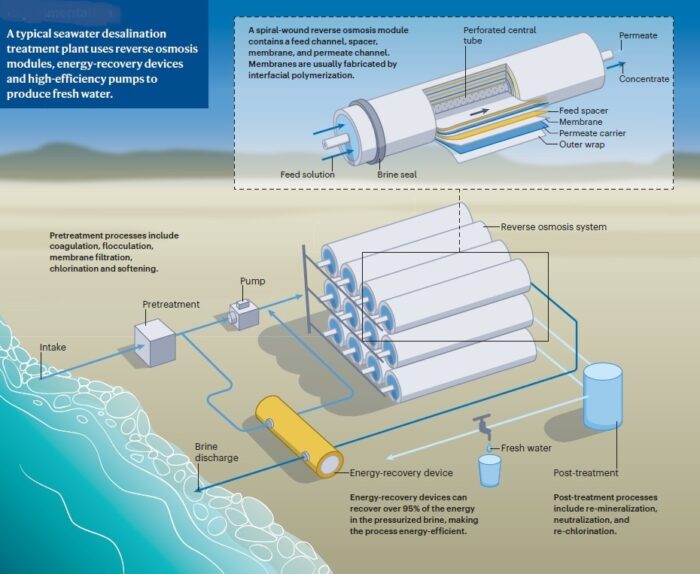

-2. Membrane processes (the more modern technology) – The best-known and most widespread of these processes is reverse osmosis. In this process, the salt water is squeezed through membranes that permit the passage of water only and prevent salts from passing through. The water that does pass through the membranes is desalinated water, and the water that remains as a solution is a concentrate that is dumped back into the sea.

Because of their high energy consumption, the evaporation processes are suitable only for countries where electricity is very inexpensive, whereas reverse osmosis is much more energy-efficient and therefore is increasingly used.

______

Desalination refers to production of drinkable water from seawater (typical salinity ranging from 30,000 to 44,000 milligrams per liter) and from brackish water (salt content below 10,000 milligrams per liter). While desalination of brackish water is less expensive, but the source itself remains limited and already almost fully used in arid regions (World Bank, 2019). Oceans, however, seem like an unlimited desalination source as they contain almost 97% of the global water endowment.

Most of the world uses groundwater as the main source of water for domestic, agriculture, and industrial use. Increasing droughts indicate that regional inland aquifers and rivers will not be able to continue to meet these water demands in the coming decades. With 67% of the global population located away from coastal regions, there is a growing need for inland desalination plants, which treat brackish or wastewater (industrial or municipal) to fill this deficit.

_

Desalination at sea and inland:

Removing salt and other impurities from sea-, ground- and wastewater could solve the world’s looming freshwater crisis. And yet, while industrial-scale seawater desalination plants do exist in coastal areas where the freshwater challenge is most acute, the process of making undrinkable water drinkable is largely out of reach for inland water sources due to the high cost of concentrate disposal. When we desalinate water, we are left with a pure water stream and a concentrated waste stream. Inland brackish water and wastewater desalination plants are costly to build and to operate because we don’t have easy disposal options for the concentrate stream. Compounding this problem is that some inland wastewaters from industrial sources can have up to 10 times higher concentration of dissolved solids than seawater. Concentrating and disposing of concentrated brine could unlock vast new water resources, but it’s just too expensive at this time.

_______

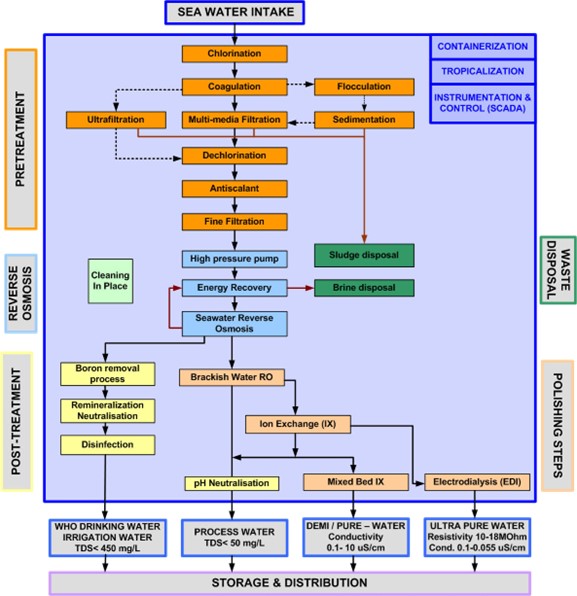

Desalination is an effective technique for removing salts and undesirable quantities of minerals from water. It produces freshwater, which is potable and also useable for sanitary purposes. Desalination of seawater and brackish water is the best alternative technique to cope with the rising issue of scarcity of potable water. This can potentially make the saline water usable on a commercial scale, but energy- and cost-effective solutions are needed along with environmental friendliness and social acceptability. The costs of desalination plants are high because a huge amount of power is required for plant operation. Reverse Osmosis (RO) is currently applied in 85% of operational desalination plants and about 91% of under-construction plants. The Middle East region accounts for 39% of global desalination capacity, and most operational desalination plants are present here. Fossil fuel (thermal) based desalination plants account for 2/3 of total desalination plants in the Middle East and North Africa (MENA) region for freshwater production. The remaining desalination plants rely on Natural gas to operate RO in the region. The excess amount of Solar and Wind energy potential is present in MENA region compared to Europe, which is abundant with geothermal energy. Solar leads the way in terms of easy access and availability in MENA region. Water desalination is a better option for people of MENA region as 50% population lives nearby coast that makes them accessible of sea water. Combining sea water desalination with solar energy technologies can make best outcome for sustainable water production. Solar assisted desalination remains a viable solution for meeting the growing water demands, yet some technical hurdles needs to be addressed for the commercialization.

_

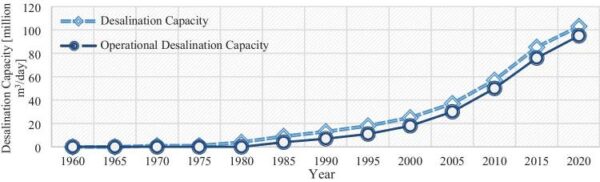

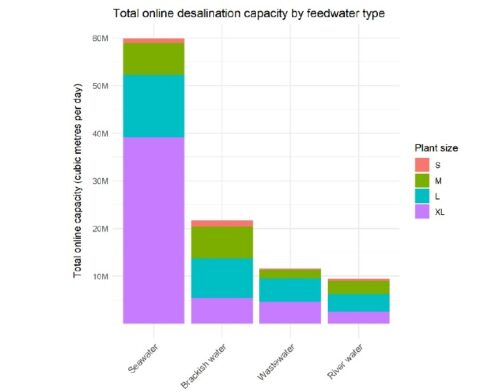

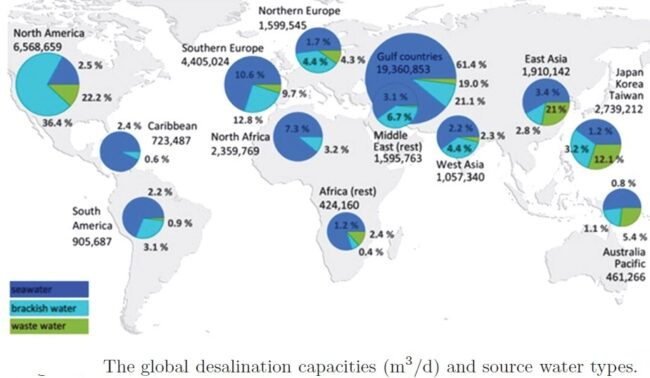

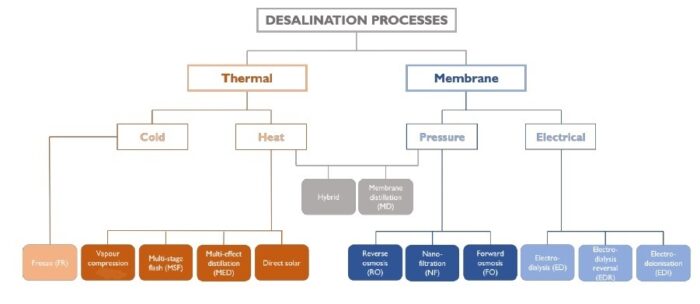

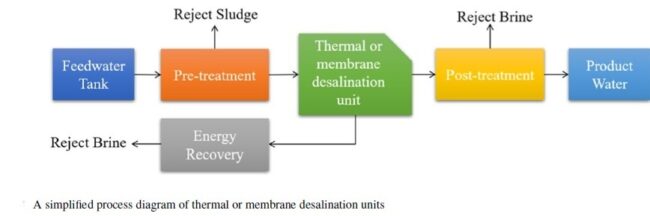

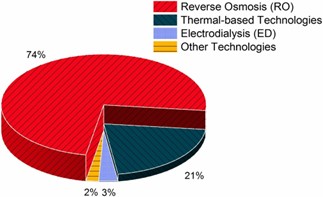

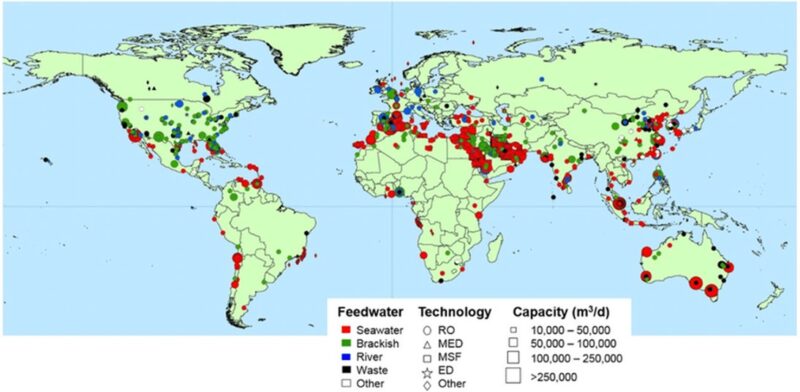

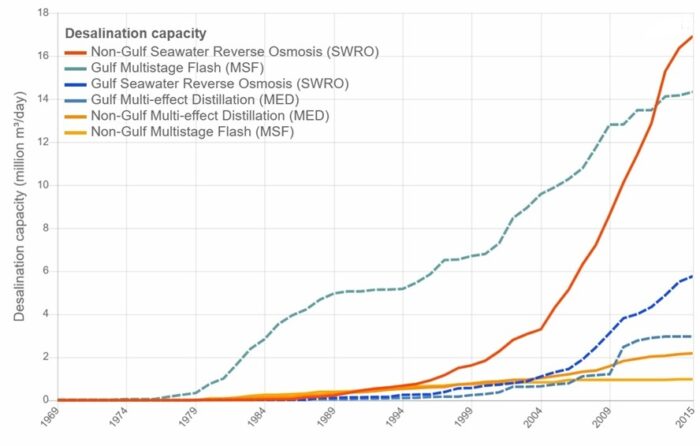

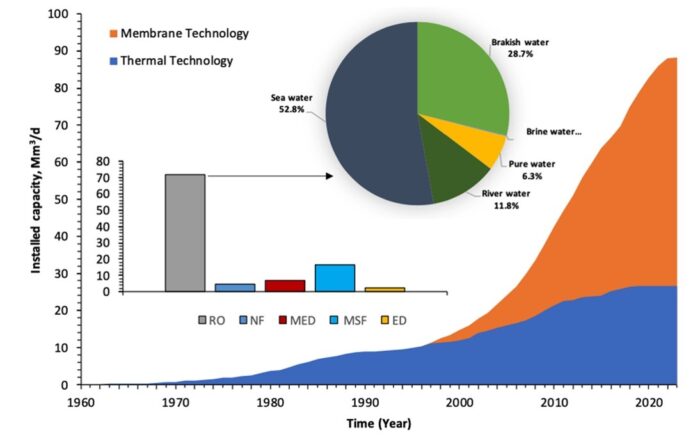

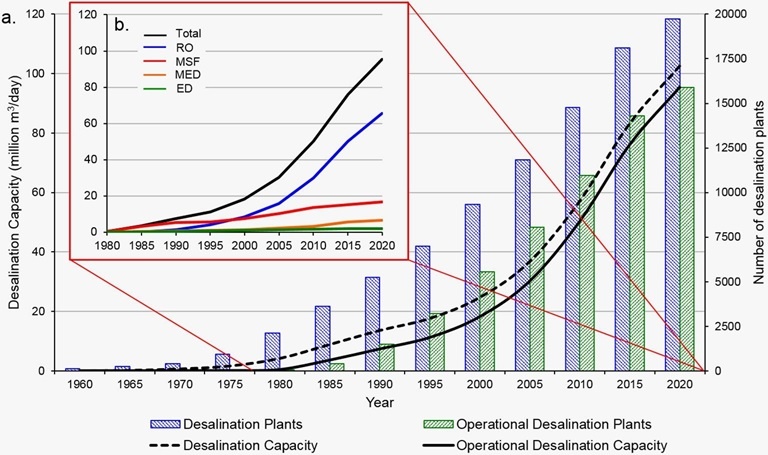

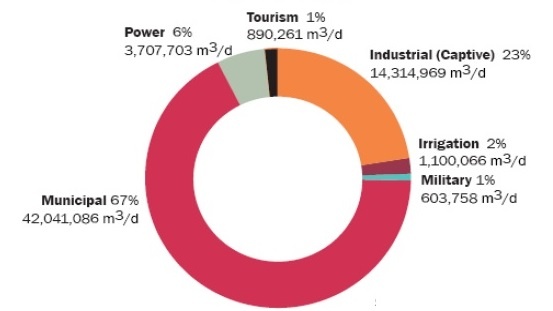

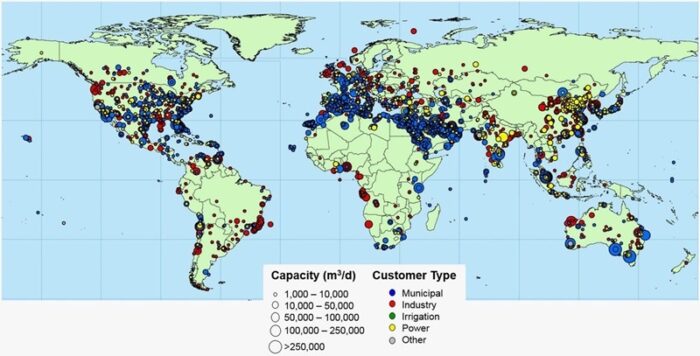

Driven by rising demand and commercial innovation, the cost of desalination has decreased significantly over the years, and it is becoming an increasingly feasible option. In 2018, 18,426 desalination plants were reported to be in operation in over 150 countries, producing 87 million cubic meters of clean water each day and supplying over 300 million people. Almost half this capacity (44 percent) is in the still-growing Middle East market, but other regions are growing even faster, notably Asia (in particular China), the United States, and Latin America. Figure below shows how the desalination industry has evolved over the sixty years. All in all, it is fair to say that desalination has solidified its position as a formidable complementary source in today’s water resources landscape.

_

Figure above shows the evolution of the desalination industry across the globe over the years.

_

Globally, nearly 2 billion people – about half of them in sub-Saharan Africa – lack access to safe drinking water. Water demand has increased by more than double the rate of population growth in the past century. The United Nations Environment Program estimates that by 2030, we could face a 40% shortfall in water supply if no drastic changes are implemented in water resources management. In fact, one-third of the world’s aquifers are in distress, mainly due to excessive withdrawals and changing rainfall patterns due to climate change. Averting major water shortages in vulnerable areas will require developing sustainable and energy-efficient ways of producing and managing water resources. Desalinated seawater is an unconventional water resource that can play a key role in achieving SDG6 and alleviating water poverty in coastal countries. However, desalination technologies are energy-intensive, so as the uptake of desalination expands globally, so will energy demand. This could be a major barrier in energy-constrained countries.

_

Desalination as risk management:

Desalination is also a good tool of risk management. Its raw material (the ocean) is practically limitless. Desalination is thus drought proof, and it is a good way to deal with climate change risks. Desalination is also a good response to exogenous risks such as dependency. Singapore, for example, opted for large-scale desalination to reduce its dependence on increasingly expensive imported water. The stable, efficient supplies of urban and industrial water that desalination provides can help governments manage a range of economic, social, and political risks.

_

Desalination as a strategic option:

Despite significant reduction in cost, desalination remains largely more expensive and needs to be used strategically to address a limited range of problems. However, today the instances of these problems are fast expanding. Desalination is proving appropriate for certain markets that require high quality and complete reliability of service and in which customers or governments can afford to pay the higher cost. For example, desalination can produce high-quality potable water that suits the needs of large cities in which there are high concentrations of people who demand a quality 24 hours per day, seven days per week water service and who are prepared to pay for that service. Desalination can also provide a reliable supply of large volumes of water to high-value industry, commerce, and tourism. In these uses, demand is going up with incomes, demographics, and urbanization; it is also in these uses that the value of water is typically the highest.

_

Desalination is of specific interest in certain locations in which the alternatives are high cost or the risk of supply failure is high. Desalination is, however, demanding in terms of location. Water has a very high ratio of bulk to value and is very expensive to lift or transport. This drives the location of a desalination plant: it should be near its raw material, the sea; it should be close to its market or point of use; and geographically it should not be too far below its market because pumping up elevation is very expensive. Hence, the typical location of a desalination plant is along a coastal city or coastal industrial zone, supplying a relatively well-off industrial, commercial, or domestic demand. Fortunately, already over one-third of the world’s population lives in urban centers bordering the ocean and in many arid parts of the world (such as the Middle East, Australia, Northern Africa, and Southern California) the population concentration along the coast exceeds 75 percent. Where the physical and socioeconomic conditions are right, seawater desalination provides a strategic solution for the sustainable, long-term satisfaction of part of this growing water demand.

_____

_____

Water transport to alleviate water scarcity:

Water transmission from rich resources to arid areas is not an innovative idea. For example, in the southwestern areas of the USA, water is transmitted for household, industrial and agricultural uses. Los Angeles now supplies 85% of its water requirements from outside of the region. Of course, water transfers from other areas are not always favorable, and protests against the transmission have always been a problem. In the USA, for instance, the diversion of the Colombia River for water supply in the western states has been a hot topic in Oregon for 35 years. Furthermore, in Spain, representatives of various parties are vigorously competing for water in the southeast (Kucera 2019). Additionally in the transmission systems, water quality is getting worse. Preventive potential for biological regrowth can be achieved by chlorinating the water. Even more disturbing, scheduling the control systems in water transmission lines is another concern for this strategy (Jung et al. 2015; Al-Jasser 2007). In addition to social and political pressures, technical problems such as long distances for water transmission, especially in high-altitude areas, makes it impossible to apply this method to all areas of the earth.

_

While noting costs are falling, and generally positive about the technology for affluent areas in proximity to oceans, a 2005 study argued, Desalinated water may be a solution for some water-stress regions, but not for places that are poor, deep in the interior of a continent, or at high elevation. Unfortunately, that includes some of the places with the biggest water problems, and, indeed, one needs to lift the water by 2000 m, or transport it over more than 1600 km to get transport costs equal to the desalination costs. Thus, it may be more economical to transport fresh water from somewhere else than to desalinate it. In places far from the sea, like New Delhi, or in high places, like Mexico City, transport costs could match desalination costs. Desalinated water is also expensive in places that are both somewhat far from the sea and somewhat high, such as Riyadh and Harare. By contrast in other locations transport costs are much less, such as Beijing, Bangkok, Zaragoza, Phoenix, and, of course, coastal cities like Tripoli. After desalination at Jubail, Saudi Arabia, water is pumped 320 km inland to Riyadh. For coastal cities, desalination is increasingly viewed as a competitive choice.

_

The costs of water produced by desalination have dropped considerably over the years as a result of reductions in price of equipment, reductions in power consumption and advances in system design and operating experiences. As the conventional water supply tends to be more expensive due to overexploitation of aquifers and increasing contaminated water resources, desalted water becomes a viable alternative water source. Desalination costs are competitive with the operation and maintenance costs of long-distance water transport system. As Saudi Arabia has already demonstrated, water can be pipped inland to landlocked cities which means desalination is not limited to coastal cities and can ensure the prosperity of sizeable regions.

_____

_____

Section-4

Introduction to desalination:

The desalting of seawater is an ancient notion. Aristotle described an evaporation method used by Greek sailors of the 4th century BCE. An Arab writer of the 8th century CE produced a treatise on distillation. In the 19th century the development of steam navigation created a demand for noncorroding water for boilers, and the first patent for a desalination process was granted in England in 1869. The same year, the first water-distillation plant was built by the British government at Aden, to supply ships stopping at the Red Sea port. The first large still to provide water for commercial purposes was built in 1930 in Aruba, near Venezuela. By 2019 about 18,000 desalination plants producing a total of more than 95 million cubic metres (in excess of 3.4 billion cubic feet) of potable water per day were in operation throughout the world.

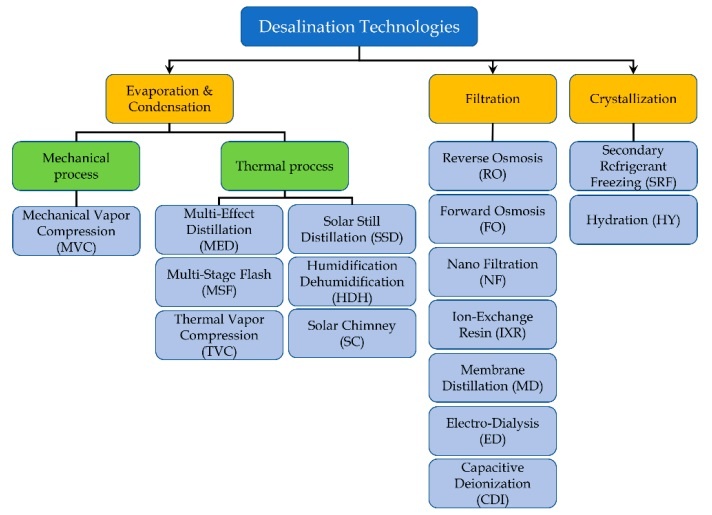

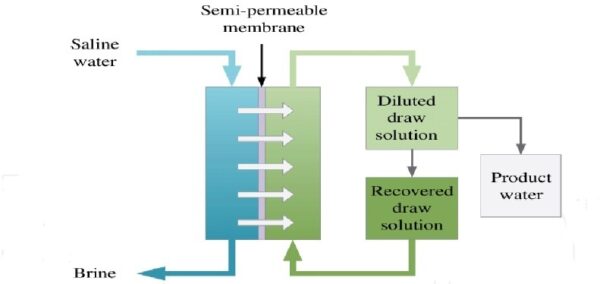

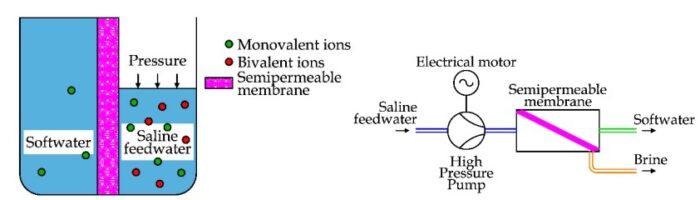

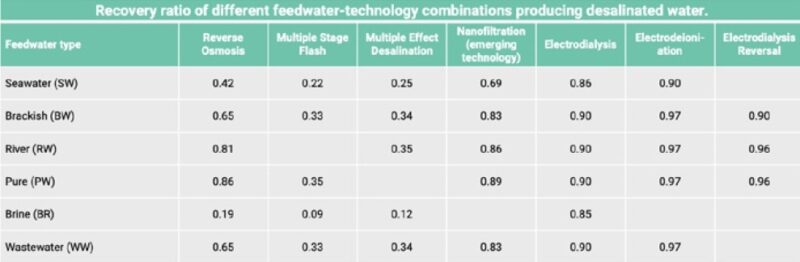

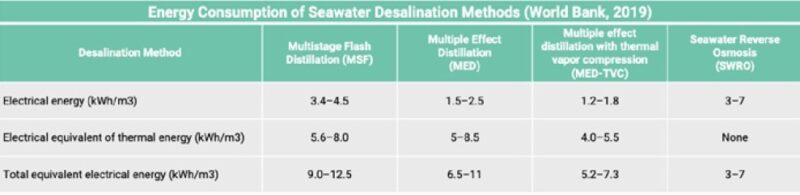

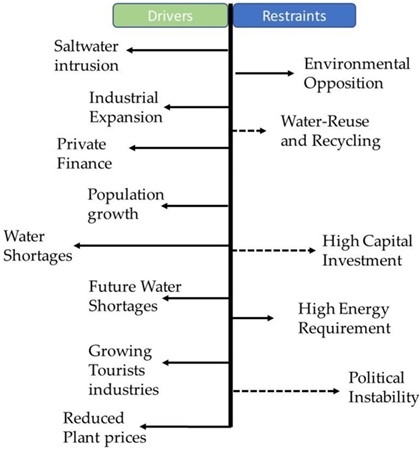

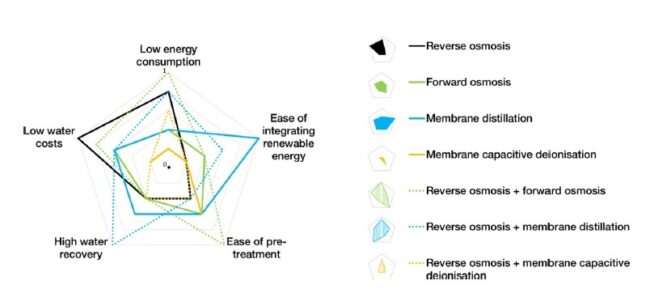

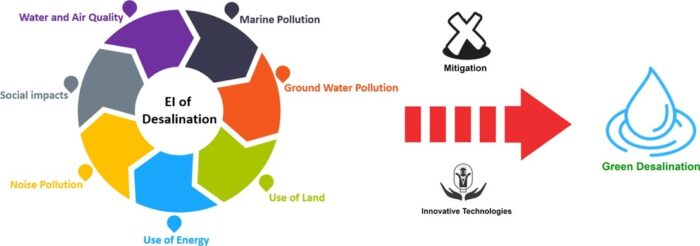

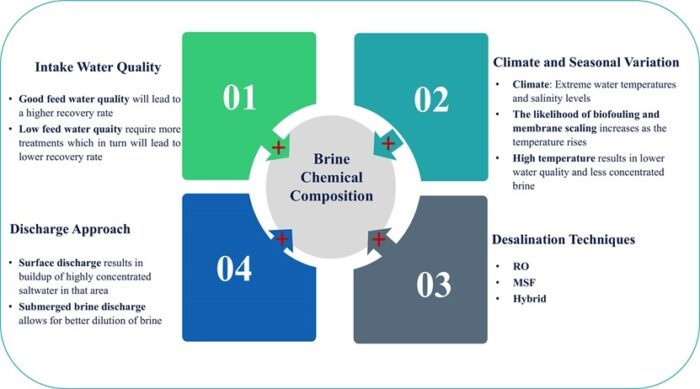

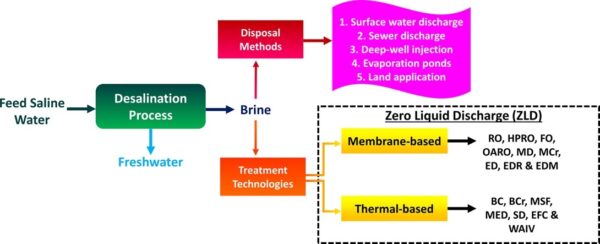

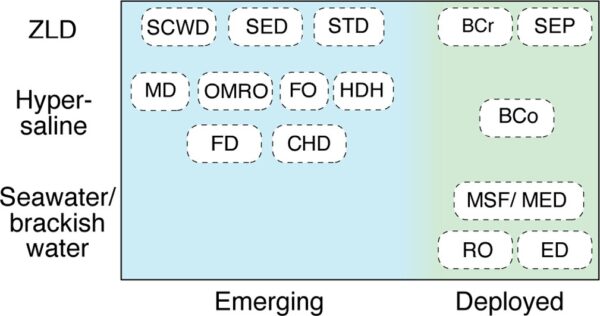

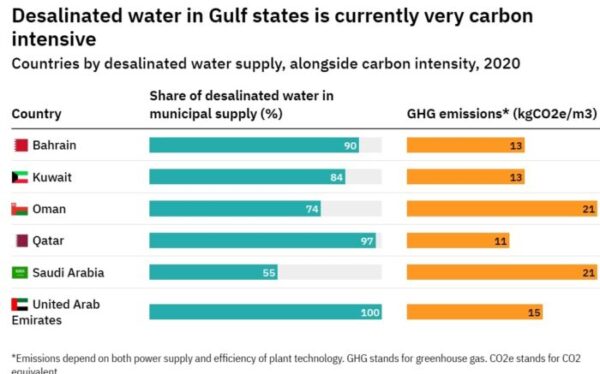

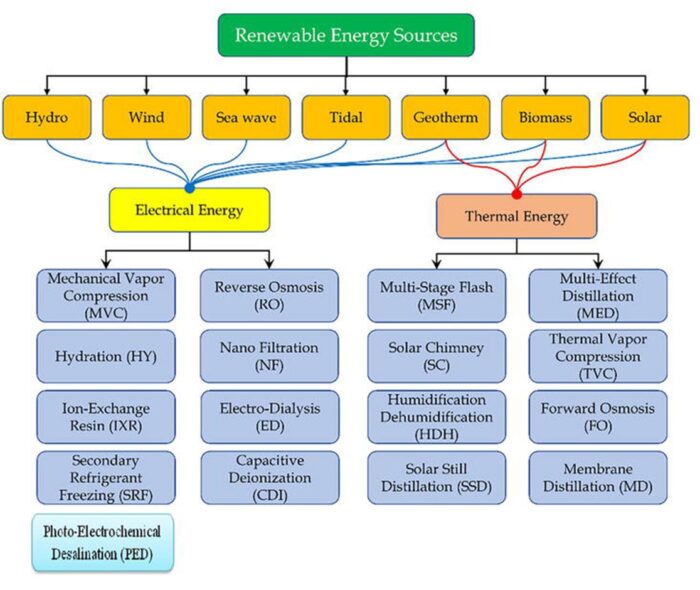

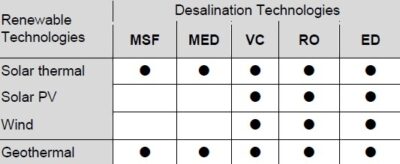

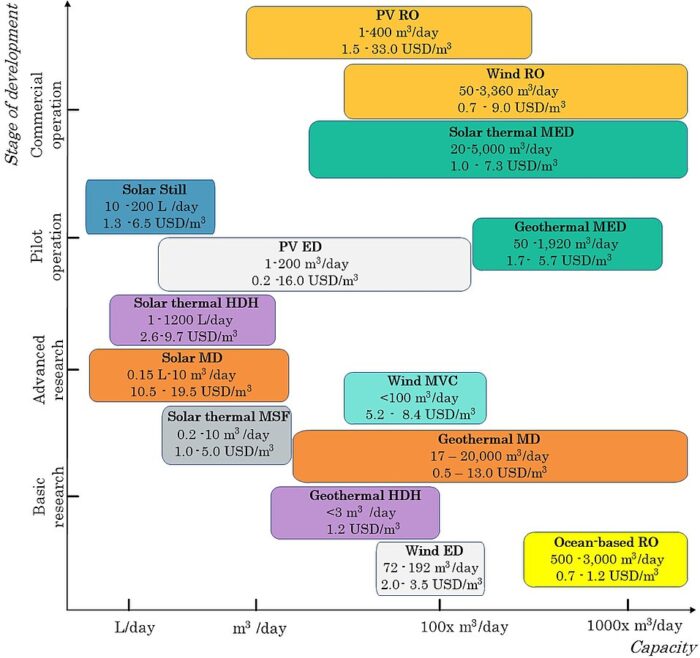

_