Dr Rajiv Desai

An Educational Blog

HYDROGEN

Hydrogen:

_

_

Section-1

Prologue:

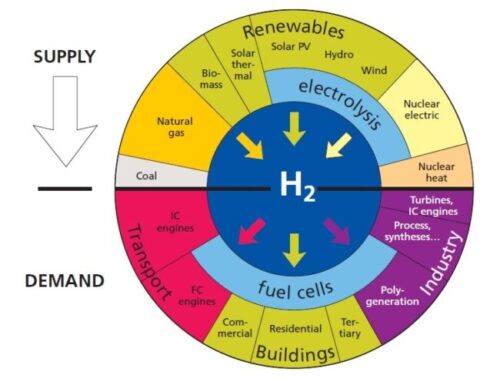

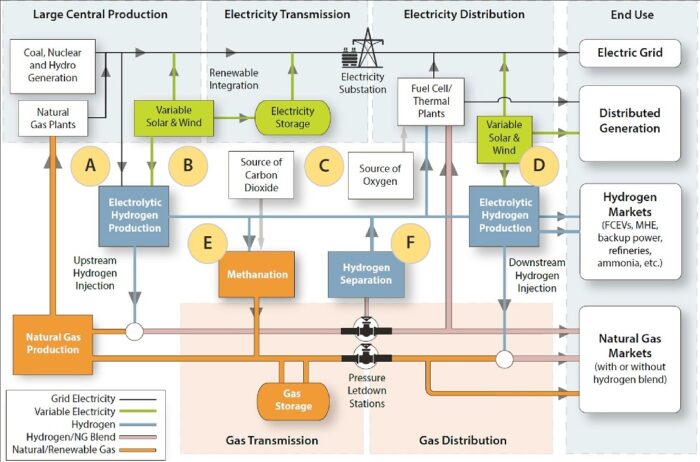

Primary energy sources include fossil fuels (petroleum, natural gas, and coal), nuclear energy, and renewable sources of energy. Energy carriers include electricity and heat as well as solid, liquid and gaseous fuels. They occupy intermediate steps in the energy-supply chain between primary sources and end-use applications. Energy carriers allow the transport of energy in a usable form from one place to another. Hydrogen is an energy carrier, not an energy source and can deliver or store a tremendous amount of energy. Hydrogen is the chemical element with the symbol H and atomic number 1. H is in the upper left corner of the Periodic Table. Hydrogen is the most basic chemical element — just one proton and one electron — and makes up nearly three-quarters of the mass in the universe. Stars such as the Sun are mainly composed of hydrogen in the plasma state. A molecule of hydrogen consists of two protons and two electrons held together by electrostatic forces with the molecular formula H2. Most of the hydrogen on Earth exists in forms such as water and organic compounds.

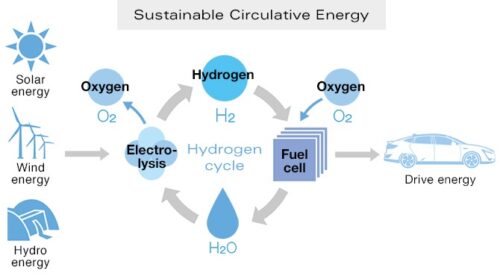

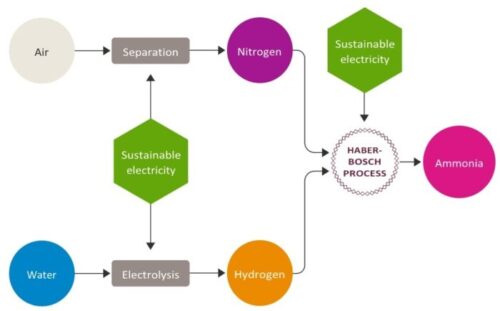

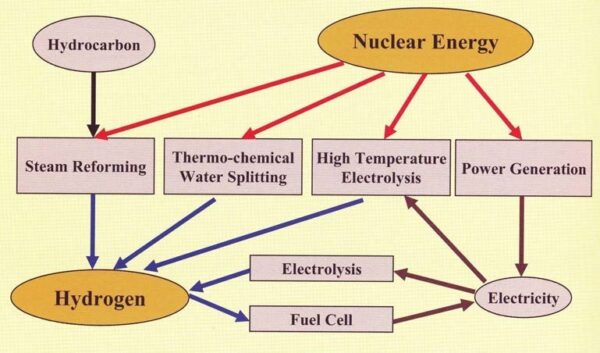

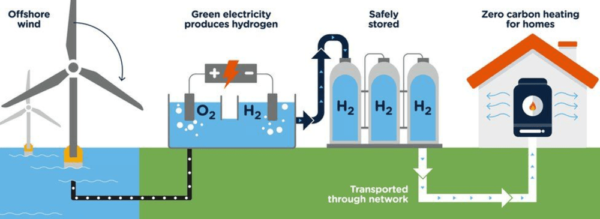

When Ahmed Sheikh Yamani, Saudi oil minister during the oil shocks of the 1970s and 80s, famously said that “the Stone Age did not end for lack of stone, and the oil age will end long before the world runs out of oil”, he was not thinking of renewable energy and electric vehicles, he was thinking of hydrogen. Hydrogen is a fascinating energy carrier. It can be produced from electricity and water. Its conversion to heat or power is simple and clean. When combusted with oxygen, hydrogen forms water. No pollutants are generated or emitted. The water is returned to nature where it originally came from. But hydrogen, the most common chemical element on the planet, does not exist in nature in its pure form. It has to be separated from chemical compounds, by electrolysis from water or by chemical processes from hydrocarbons or other hydrogen carriers. The electricity for the electrolysis may eventually come from clean renewable sources such as solar radiation, kinetic energy of wind and water or geothermal heat. Therefore, green hydrogen may become an important link between renewable energy and chemical energy carriers. Jules Verne told us about green hydrogen more than 125 years ago in his novel The Mysterious Island: “What are they going to burn instead of coal?… Water. Water broken down into its elements by electricity will one day be used as fuel.” In electrolysis, we put in electricity and water and we get out hydrogen and oxygen. In a fuel cell, we put in hydrogen and air (oxygen), and we get out electricity and water.

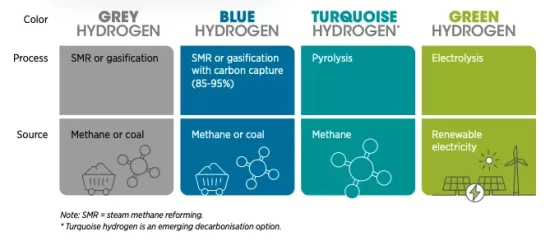

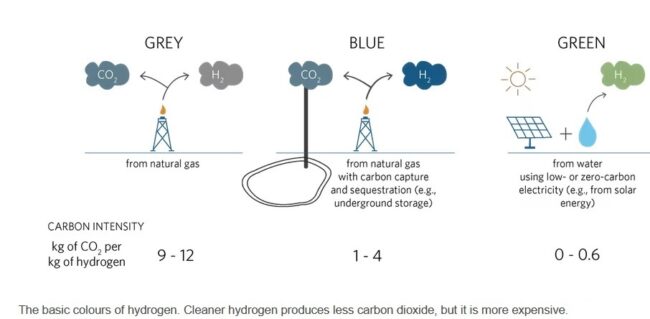

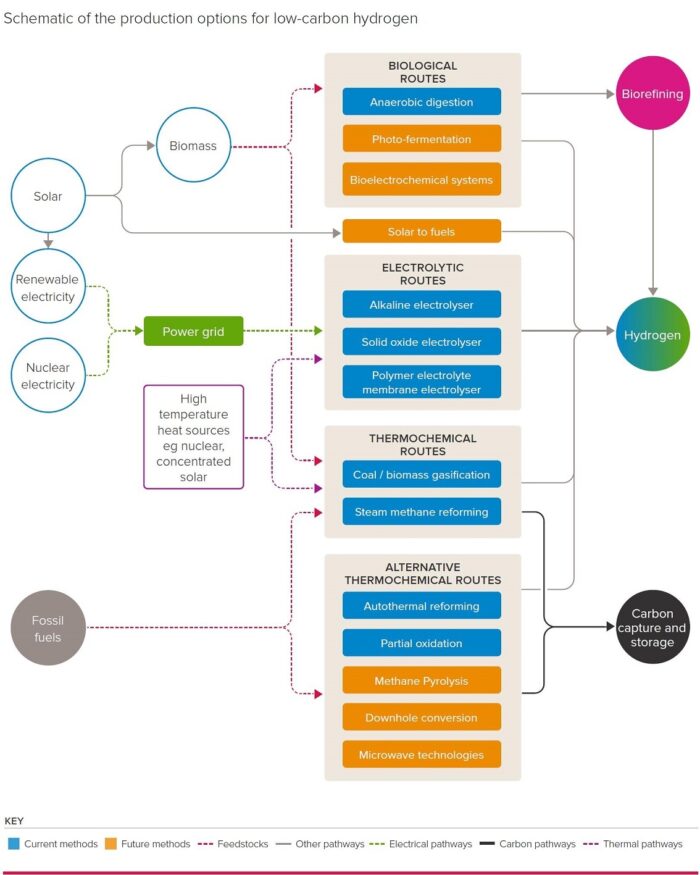

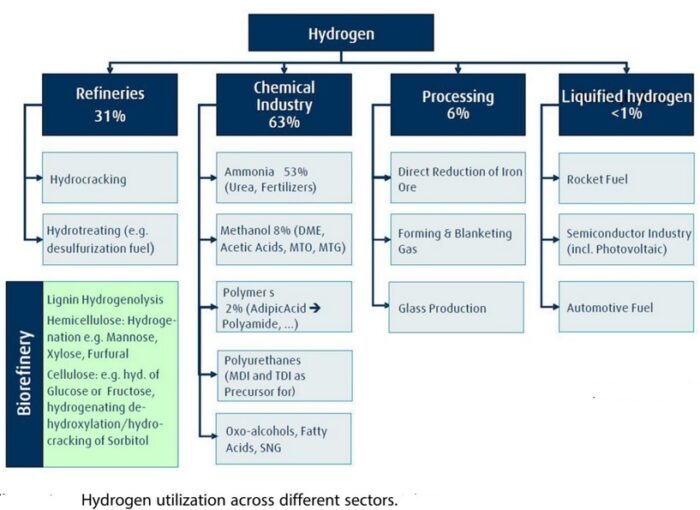

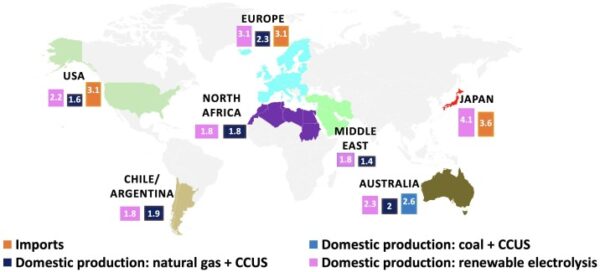

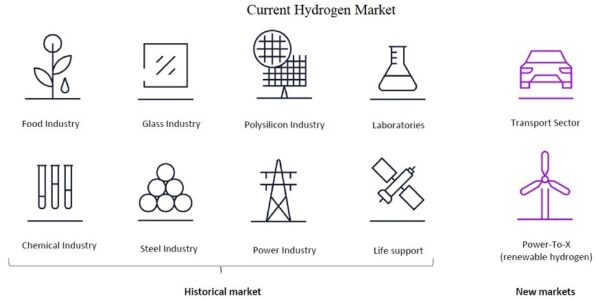

Despite a 5.8% drop in global carbon emissions in 2020 due to the COVID-19 pandemic, emissions are still at critical levels. Global CO2 emissions were 31.5Gt – an increase of 54% since 1990. With that in mind, the quest to find a viable alternative to carbon-based fuel and energy production processes is continually accelerating. We must remember that doing nothing is not an option. We cannot continue to burn fossil fuels and meet climate change obligations, it’s impossible. From passenger vehicles to domestic energy, those at the forefront of alternative fuel and energy storage technology are exploring options. Today, the world produces 75 million tons of hydrogen each year. Nearly all of the hydrogen is used by industry for refining petroleum, treating metals, producing fertilizer, and processing foods. Most of it is generated from fossil fuels, mainly natural gas and coal. This accounts for 6% of the global natural gas consumption, 2% of the global coal consumption, and results in 830 million tons of carbon dioxide being released every year – almost as much as Germany’s annual CO2 emissions. There are three main types of hydrogen discussed today. First, ‘grey’ hydrogen. The vast majority of hydrogen in use — and there is plenty of it, mainly in industry — is made from natural gas and coal. The process emits CO2. ‘Grey’ hydrogen becomes ‘blue’ hydrogen when the CO2 given out during its production is locked up through carbon capture and storage (CCS) processes. But while the CO2 output is lowered, this process is quite expensive. ‘Grey’ and ‘blue’ hydrogen, thus, are both produced by the same processes, the only difference for ‘blue’ hydrogen being that the CO2 produced is sequestered. Finally, ‘green’ or ‘renewable’ hydrogen — which every hydrogen advocate says is the ultimate goal — is made from the electrolysis of water powered by renewables and it will help to substantially reduce emissions. Production cost of grey hydrogen is $1 per kilogram and blue is $2 per kilogram at the cheapest. Green hydrogen costs upwards of $4 per kilogram.

Legend has it that when Henry Ford was asked if he developed the Model T in response to customer demands, he famously responded: “If I had asked people what they wanted, they would have said faster horses.” This quote has been used for 100 years to describe the paradox between what customers perceive they want based on their own life experiences versus what could be possible based on current science and technology. Today’s energy transformation is caught in a similar paradox. The “faster horses” offered by cheap natural gas and oil need to be replaced with technology that can minimize CO2 emissions and mitigate climate change. Hydrogen technologies offer the potential to change the way we produce, store, and use energy by enabling more widespread use of carbon free energy sources.

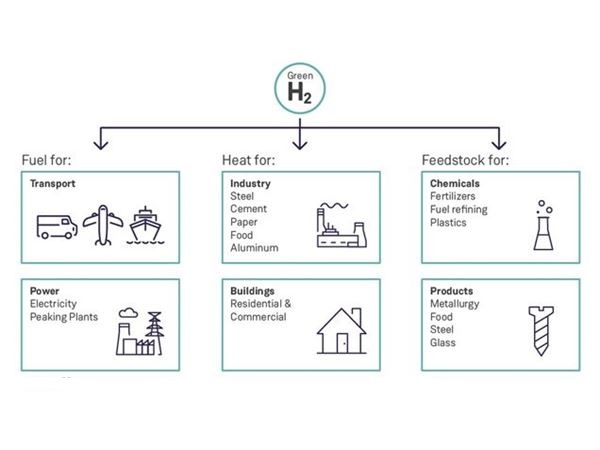

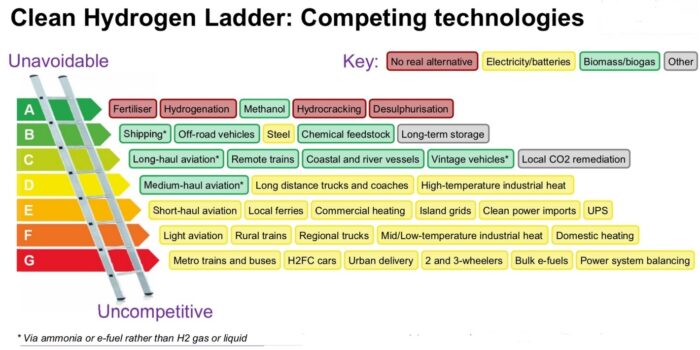

A new star has exploded back onto the climate scene: hydrogen. It offers possibilities to move away from fossil fuels, but it brings its own challenges. For climate experts, green or renewable hydrogen — made from the electrolysis of water powered by solar or wind — is indispensable to climate neutrality. It features in all eight of the European Commission’s net zero emissions scenarios for 2050. In theory, it can do three things: store surplus renewables power when the grid cannot absorb it, help decarbonize hard-to-electrify sectors such as long-distance transport and heavy industry, and replace fossil fuels as a zero-carbon feedstock in chemicals and fuel production. The International Energy Agency lauded its “vast potential” in a first ever report on hydrogen in June 2019. Bloomberg New Energy Finance said clean hydrogen “can help address the toughest third of global greenhouse gas emissions by 2050” in March 2020. Net-zero requires a full fossil fuel phase-out. It puts the spotlight on gas for the first time. And the gas industry is turning to hydrogen for a new lease of life. Yet the climate community is cautious. The risk is that the hydrogen hype triggers a reversal of priorities. Energy efficiency, renewables, nuclear, switch from coal to natural gas and direct electrification are the bulk solutions to climate change. Moreover, the climate impact of hydrogen depends entirely on how it is made. Hydrogen is not a technology; it is an energy carrier that can be produced clean or dirty.

With global warming and climate change becoming an ever-increasing issue, sustainable power is growing in demand. In the last decade, electric vehicles have had a surge in popularity, but could hydrogen be a better option? Elon Musk, the CEO of electric car company Tesla stated that hydrogen cars are ‘mind-bogglingly stupid’. Hydrogen’s impact in the car market may indeed remain modest due to efficiency and economic problems. However, ongoing improvements along with advantages of abundance, low emissions and high energy density mean that in the new market of sustainable larger vehicles hydrogen power will soon gain significant market share. The hydrogen economy could be all-encompassing, or it could fill a series of niches, depending on hydrogen availability, cost and performance relative to alternatives, for each potential application. Are you for or against hydrogen? That seems to be the wrong question. The correct question is: where do you really need to use it?

_______

Abbreviations and synonyms:

°C = degree Celsius

K = kelvin, the SI base unit of temperature

EJ = exajoule

Gt/yr = gigatons per year

GW = gigawatt

h = hour

kg = kilogram

kW = kilowatt

kWh = kilowatt hour = unit of electricity

One tonne of oil equivalent (toe) = 41.868 GJ

MJ = megajoule = 106 Joule

GJ = gigajoule= 109 Joule = 0.95 million Btu

1 kWh = 3.6 megajoules = 3412.14 Btu

Btu = British thermal unit = the amount of energy required to heat one pound of water by one degree Fahrenheit

1 Btu = 1055.055853 Joule

MPa = megapascal

MW = megawatt

Nm3 = normal cubic meter (under normal or standard conditions of temperature & pressure)

TWh = terawatt hour

ALK = alkaline

BEV = battery electric vehicle

CAPEX = capital expenditure

CCS = carbon capture and storage

CCU = carbon capture and utilisation

COP21 = 21st Conference of the Parties to UN Framework Convention on Climate Change

CO₂ = CO2 = carbon dioxide

CSP = concentrated solar power

DRI-H = direct reduction via hydrogen

e-fuel = electrofuel

FCEV = fuel cell electric vehicle

HHV = high heating value

HRS = hydrogen refuelling station

H₂ = H2 = hydrogen

LH2 = liquid hydrogen

LDV = light-duty vehicle

LCOH = levelised cost of hydrogen

LHV = lower heating value

LOHC = liquid organic hydrogen carrier

OPEX = operating expenditure

PEM = proton exchange membrane

PV = photovoltaic

P2G = power-to-gas

P2X = power-to-x

P2P = power-to-power

SMR = steam-methane reforming

SOEC = solid oxide electrolyser cell

VRE – variable renewable energy

FC = fuel cell

gal = gallon

ICE = internal combustion engine

IHIG = International Hydrogen Infrastructure Group

Psi = pounds per square inch

CNG = Compressed Natural Gas

HCNG = Hydrogen and CNG blend

CO = Carbon monoxide

H2O = Water

IRENA = International Renewable Energy Agency

LCA = Life cycle assessment

LPG = Liquefied petroleum gas

MCFC = Molten carbonate fuel cell

PEMEL = Proton exchange membrane electrolyser

PEMFC = Proton exchange membrane fuel cell

AEL = alkaline electrolyzer

TOC = total cost of ownership

One bar = 0.987 atm = 14.50 psi = 100,000 pascals (N/m2) = 0.1 MPa = 750.06 mmHg pressure

CHP = Combined heat and power

CHP is concurrent production of electricity or mechanical power and useful thermal energy (heating and/or cooling) from a single source of energy. It is type of distributed generation, which, unlike central station generation, is located at or near the point of consumption. CHP technology is often referred to as cogeneration, but there are important differences. Cogeneration is the process where a simple cycle gas turbine produces electricity and steam—as well as the steam that is used in other processes, such as drying. However, the steam is not used to drive a steam turbine. CHP combined-cycle power plants can deliver concurrent production of electricity and useful thermal energy from a common fuel. The captured thermal energy (steam or hot water) can be used for processes like heating and cooling, and to generate power for other industrial purposes. CHP applications can operate at about 75% efficiency, a significant improvement over the national average of about 50% for these services when provided separately.

Feedstock:

Feedstock is raw material used for processing or manufacturing another product. As feedstock, the term connotes it is a bottleneck asset critical to the production of other products. A feedstock is also defined as any renewable, biological material that can be used directly as a fuel, or converted to another form of fuel or energy product. Hydrogen is a feedstock for the production of ammonia, various plastics, refining, synthetic fuels, stationary power and mobile power.

______

Heat Values of Various Fuels:

The heat value of a fuel is the amount of heat released during its combustion. Also referred to as energy or calorific value, heat value is a measure of a fuel’s energy density, and is expressed in energy (joules) per specified amount (e.g., kilograms).

HHV and LHV:

HHV (High Heating Value) and LHV (Low Heating Value) are engineering terms used since the 19th century.

All biomass fuels, such as wood, straw, charcoal and others, contain carbon, hydrogen and oxygen, which are described in this chemical formula CxHyOz. In a complete combustion, organic fuels react with oxygen molecules in the atmosphere to form two products: carbon dioxide CO2and water H2O and to release heat. This heat released is called heat of combustion. Some of the heat released are used to vaporize the existing moisture in the fuel and the water product. Higher heating value (HHV) is calculated with the product of water being in liquid form while lower heating value (LHV) is calculated with the product of water being in vapor form. LHV number usually is more realistic. The chart below compares HHV and LHV values for several fuels. Notice that the difference is greater for hydrogen. Any device that makes hydrogen will look worse if LHV numbers are used to calculate efficiency. The error lies in mixing LHV and HHV numbers inconsistently. In this article, LHV of hydrogen 120MJ/kg is used frequently.

|

|

HHV |

LHV |

Difference |

|

Hydrogen |

142 MJ/kg |

120 MJ/kg |

18% |

|

Natural Gas |

38 MJ/kg |

35 MJ/kg |

8% |

|

Gasoline |

35 MJ/kg |

32 MJ/kg |

11% |

_______

Units for Hydrogen Production and Use:

Hydrogen production capacity is usually given in units of standard cubic feet (scf) produced per day, normal cubic meters (Nm3) per day, gigajoules per day, or kilowatts of hydrogen output (on a continuous basis). Specific capital costs for production plants are expressed as dollars ($) per kilowatt of hydrogen output capacity. All energy and power units are usually based on the higher heating value (HHV) of hydrogen. Hydrogen storage capacity is given in volume units (scf or Nm3), in tons, or in energy stored (gigajoules). Capital costs for storage are given in $ per ton of hydrogen stored or $ per gigajoule stored.

Because hydrogen is delivered in a compressed gaseous form, volume measurement would not be suitable due to the dependency on pressure and temperature of the gas. So hydrogen is measured in kilograms. A 100% efficient electrolyser requires 39 kWh of electricity to produce 1 kg of hydrogen. The devices today require as much as 50 kWh/kg. So, if electricity costs are 0.05 US$/kWh, the power cost for the electrolysis process alone is 2.50 US$/kg of hydrogen.

A kilogram of hydrogen contains 141.8 megajoules of energy. In electrical terms, the energy density of hydrogen is equal to 33.6 kWh of usable energy per kg, versus diesel which only holds about 12–14 kWh per kg. What this really means is that 1 kg of hydrogen, used in a fuel cell to power an electric motor, contains approximately the same energy as a gallon of diesel.

_____

Electricity units generated by power plants:

When you see a 60 watt light bulb in your house, it means that the light bulb draws electricity from the grid at a rate of 60 Watts, or 60 Joules per second.

One electricity unit = 1 kilowatts generated for 1 hour = 1 kwh = 3.6 megajoules

A 60 watt bulb will draw 1 unit electricity in 16.6 hour.

300 MW power station will produce 300 million watts per second; that is 300,000 kilowatts per second; that is 300,000 kilowatt hour every hour; that is 300,000 units of electricity generated every hour; that is 7.2 million units of electricity per day. So a 300 MW power station will generate 7.2 million units of electricity in 24 hours provided it is 100 % efficient. In other words, 300 MW power station will produce 300 MWh electricity every hour.

_______

_______

Section-2

Hydrogen basics:

Hydrogen is the chemical element with the symbol H and atomic number 1. Hydrogen is the lightest element. At standard conditions hydrogen is a gas of diatomic molecules having the formula H2. Hydrogen is found naturally in the molecular H2 form. At room temperature and under normal pressure, hydrogen is a colorless, odourless and non-poisonous gas which is lighter than air and helium. In the environment H2 can be freely found in volcanic gasses, but its lightness allows it to escape from the earth’s atmosphere. Hydrogen burns with a pale blue, almost invisible flame. At temperatures under –253 ºC hydrogen is in a liquid state. Hydrogen is the most abundant chemical substance in the universe, constituting roughly 75% of all normal matter. Stars such as the Sun are mainly composed of hydrogen in the plasma state. Most of the hydrogen on Earth exists in molecular forms such as water and organic compounds. For the most common isotope of hydrogen (symbol 1H, named Protium) each atom has one proton, one electron, and no neutrons.

In the early universe, the formation of protons, the nuclei of hydrogen, occurred during the first second after the Big Bang. The emergence of neutral hydrogen atoms throughout the universe occurred about 370,000 years later during the recombination epoch, when the plasma had cooled enough for electrons to remain bound to protons.

_

Hydrogen is an essential for life, the universe and just about everything. Life, in fact, is multiply dependent on it. Without hydrogen we wouldn’t have the Sun to give us heat and light. There would be no useful organic compounds to form the building blocks of life. And that most essential substance for life’s existence, water, would not exist. It’s only thanks to a special trick of hydrogen’s that we can use water at all. Hydrogen forms weak bonds between molecules, latching onto adjacent oxygen, nitrogen or fluorine atoms. It’s these hydrogen bonds that give water many of its properties. If they didn’t exist, the boiling point of water would be below -70 degrees Celsius. Liquid water would not feature on the Earth.

_

Hydrogen is nonmetallic, except at extremely high pressures, and readily forms a single covalent bond with most nonmetallic elements, forming compounds such as water and nearly all organic compounds. Hydrogen plays a particularly important role in acid–base reactions because these reactions usually involve the exchange of protons between soluble molecules. In ionic compounds, hydrogen can take the form of a negative charge (i.e., anion) where it is known as a hydride, or as a positively charged (i.e., cation) species denoted by the symbol H+. The H+ cation is simply a proton (symbol p) but its behavior in aqueous solutions and in ionic compounds involves screening of its electric charge by nearby polar molecules or anions. Because hydrogen is the only neutral atom for which the Schrödinger equation can be solved analytically, the study of its energetics and chemical bonding has played a key role in the development of quantum mechanics.

_

Hydrogen gas was first artificially produced in the early 16th century by the reaction of acids on metals. In 1766–81, Henry Cavendish was the first to recognize that hydrogen gas was a discrete substance, and that it produces water when burned, the property for which it was later named: in Greek, hydrogen means “water-former”.

Industrial production is mainly from steam reforming natural gas, and less often from more energy-intensive methods such as the electrolysis of water. Most hydrogen is used near the site of its production, the two largest uses being fossil fuel processing (e.g., hydrocracking) and ammonia production, mostly for the fertilizer market. Hydrogen is problematic in metallurgy because it can embrittle many metals, complicating the design of pipelines and storage tanks.

Hydrogen is the only element that can exist without neutrons. Hydrogen’s most abundant isotope has no neutrons. Hydrogen forms both positive and negative ions. It does this more readily than any other element. Hydrogen is the only atom for which the Schrödinger equation has an exact solution. Liquid hydrogen has the lowest density of any liquid. Solid, crystalline hydrogen has the lowest density of any crystalline solid. Because hydrogen is so light, the pure element isn’t commonly found on the Earth. It would just float away. The prime components of air, nitrogen and oxygen, are fourteen and sixteen times heavier, giving hydrogen dramatic buoyancy. This lightness of hydrogen made it a natural for one of its first practical uses – filling balloons. No balloon soars as well as a hydrogen balloon.

The first such aerial vessel was the creation of French scientist Jacques Charles in 1783, who was inspired by the Montgolfier brothers’ hot air success a couple of months before to use hydrogen in a balloon of silk impregnated with rubber. Hydrogen seemed to have a guaranteed future in flying machines, reinforced by the invention of airships built on a rigid frame, called dirigibles in the UK but better known by their German nickname of Zeppelins, after their enthusiastic promoter Graf Ferdinand von Zeppelin.

These airships were soon the liners of the sky, carrying passengers safely and smoothly across the Atlantic. But despite the ultimate lightness of hydrogen it has another property that killed off airships – hydrogen is highly flammable. The destruction of the vast zeppelin the Hindenburg, probably by fire caused by static electricity, was seen on film by shocked audiences around the world. The hydrogen airship was doomed.

Yet hydrogen has remained a player in the field of transport because of the raw efficiency of its combustion. Many of NASA’s rockets, including the second and third stages of the Apollo Program’s Saturn V and the Space Shuttle main engines, are powered by burning liquid hydrogen with pure oxygen.

_

Basics of Hydrogen element:

|

Discovery date |

1766 |

|

Discovered by |

Henry Cavendish |

|

Origin of the name |

The name is derived from the Greek ‘hydro’ and ‘genes’ meaning water forming. |

|

Allotropes |

H2 |

|

Atomic number |

1 |

|

State at 20°C |

Gas |

|

Melting point |

−259.16°C, −434.49°F, 13.99 K |

|

Boiling point |

−252.879°C, −423.182°F, 20.271 K |

|

Density (g cm−3) |

0.000082 |

|

Relative atomic mass |

1.008 |

|

Key isotopes |

1H, 2H |

_

History of hydrogen:

Hydrogen has received increased attention as an environmentally friendly option to help meet today’s energy needs. The road leading to an understanding of hydrogen’s energy potential presents a fascinating tour through scientific discovery and industrial ingenuity.

1766 – Hydrogen was first identified as a distinct element by British scientist Henry Cavendish after he separated hydrogen gas by reacting zinc metal with hydrochloric acid. In a demonstration to the Royal Society of London, Cavendish applied a spark to hydrogen gas yielding water. This discovery led to his later finding that water (H2O) is made of hydrogen and oxygen.

1783 – Jacques Alexander Cesar Charles, a French physicist, launched the first hydrogen balloon flight. Known as “Charliere,” the unmanned balloon flew to an altitude of three kilometers. Only three months later, Charles himself flew the first manned hydrogen balloon.

1788 – Building on the discoveries of Cavendish, French chemist Antoine Lavoisier gave hydrogen its name, which was derived from the Greek words – “hydro” and “genes,” meaning “water” and “born of.”

1800 –English scientists William Nicholson and Sir Anthony Carlisle discovered that applying electric current to water produced hydrogen and oxygen gases. This process was later termed “electrolysis.”

1839 – The fuel cell effect, combining hydrogen and oxygen gases to produce water and an electric current, was discovered by Swiss chemist Christian Friedrich Schoenbein.

1845 – English scientist and judge Sir William Grove demonstrated Schoenbein’s discovery on a practical scale by creating a “gas battery.” For his achievement he earned the title “Father of the Fuel Cell.”

1905 – Germans developed the Haber process to make ammonia from nitrogen in the air and hydrogen. Ammonia is the starting point for making fertilizer and explosives.

1920s – German engineer Rudolf Erren converted the internal combustion engines of trucks, buses and submarines to use hydrogen or hydrogen mixtures. British scientist and Marxist writer J.B.S. Haldane introduced the concept of renewable hydrogen in his paper, Science and the Future, by proposing that “there will be great power stations where during windy weather the surplus power will be used for the electrolytic decomposition of water into oxygen and hydrogen.”

1931 – Harold Urey and his colleagues at Columbia University in the US detected a second, rarer, form of hydrogen. This has twice the mass of normal hydrogen, and they named it deuterium.

1937 – After ten successful trans-Atlantic flights from Germany to the United States, the Hindenburg, a dirigible inflated with hydrogen gas, erupted into flames while landing in Lakewood, New Jersey.

1958– The United States formed the National Aeronautics and Space Administration (NASA). NASA’s space program currently uses the most liquid hydrogen worldwide, primarily for rocket propulsion and as a fuel for fuel cells. NASA uses hydrogen both as a fuel for its rockets and for fuel cells to generate electricity.

1959– Francis T. Bacon of Cambridge University in England built the first practical hydrogen-air fuel cell. The 5-kilowatt (kW) system powered a welding machine. He named his fuel cell design the “Bacon Cell.” Later that year, Harry Karl Ihrig, an engineer for the Allis – Chalmers Manufacturing Company, demonstrated the first fuel cell vehicle: a 20–horsepower tractor. Hydrogen fuel cells, based upon Bacon’s design, have been used to generate on-board electricity, heat and water for astronauts aboard the famous Apollo spacecraft and all subsequent space shuttle missions.

1970 – Electrochemist John O’M. Bockris coined the term “hydrogen economy.” He later published Energy: The Solar-Hydrogen Alternative, describing his envisioned hydrogen economy where cities in the United States could be supplied with solar energy.

1972– A 1972 Gremlin, modified by The University of California at Los Angeles, entered the 1972 Urban Vehicle Design Competition and won first prize for the lowest tailpipe emissions. Students converted the Gremlin’s internal combustion engine to run on hydrogen supplied from an onboard tank.

1973–The OPEC oil embargo and the resulting supply shock suggested that the era of cheap petroleum had ended and that the world needed alternative fuels. The development of hydrogen fuel cells for conventional commercial applications began.

1974– Professor T. Nejat Veziroglu of the University of Miami, FL, organized The Hydrogen Economy Miami Energy Conference (THEME), the first international conference held to discuss hydrogen energy. Following the conference, the scientists and engineers who attended the THEME conference formed the International Association for Hydrogen Energy (IAHE).

1977– International Energy Agency (IEA) was established in response to global oil market disruptions. IEA activities included the research and development of hydrogen energy technologies. The U.S. Department of Energy (DOE) was also created.

1978– National Science Foundation transferred the Federal Hydrogen R&D Program to the U.S. DOE.

1988– The Soviet Union Tupolev Design Bureau successfully converted a 164-passenger TU-154 commercial jet to operate one of the jet’s three engines on liquid hydrogen. The maiden flight lasted 21 minutes.

1989– The National Hydrogen Association (NHA) formed in the United States with ten members. Today, the NHA has nearly 100 members, including representatives from the automobile and aerospace industries, federal, state and local governments, universities, researchers, utilities and energy providers. The International Organization for Standardization’s Technical Committee for Hydrogen Technologies was also created.

1990– The world’s first solar powered hydrogen production plant at Solar-Wasserstoff-Bayern, a research and testing facility in southern Germany, became operational. The U.S. Congress passed the Spark M. Matsunaga Hydrogen, Research, Development and Demonstration Act (PL 101-566), which prescribed the formulation of a 5-year management and implementation plan for hydrogen research and development in the United States. The Hydrogen Technical Advisory Panel (HTAP) was mandated by the Matsunaga Act to ensure consultation on and coordination of hydrogen research.

1991– Georgetown University in Washington, D.C. begins development of three 30-foot Fuel Cell Test Bed Buses (TBB) as part of their Generation I Bus Program. In 2001, Georgetown finished their second Generation II bus, which uses hydrogen from methanol to power a 100kW fuel cell “engine.”

1992– The Partnership for a New Generation of Vehicles (PNGV), a cooperative R&D program, was established by the Clinton Administration as a joint effort between the government and automobile manufactures for the research and development of new vehicles technologies and alternative fuels, including hydrogen.

1994– Daimler Benz demonstrated the NECAR I (New Electric CAR), its first hydrogen fuel cell vehicle, at a press conference in Ulm, Germany.

1995– The Chicago Transit Authority unveiled the first of their three hydrogen fuel cell buses. The small pilot fleet began operation the following year.

1997– Retired NASA engineer Addison Bain challenged the belief that hydrogen caused the Hindenburg accident. The hydrogen, Bain demonstrated, did not cause the catastrophic fire but rather it was the combination of static electricity and highly flammable material on the skin of the airship.

1998– Iceland unveiled a plan to create the first hydrogen economy by 2030.

1999– Europe’s first hydrogen fueling stations were opened in the German cities of Hamburg and Munich. The Royal Dutch/Shell Company committed to a hydrogen future by forming a hydrogen division. Also, a consortium of Icelandic institutions, headed by the financial group New Business Venture Fund, partnered with Royal Dutch/Shell Group, DaimlerChrysler (a merger of Daimler Benz and Chrysler) Norsk Hydro to form the Icelandic Hydrogen and Fuel Cell Company, Ltd. to further the hydrogen economy in Iceland.

2001– Ballard Power Systems launched the world’s first volume-produced proton exchange membrane (PEM) fuel cell system designed for integration into a wide variety of industrial and consumer end-product applications.

2002– Executives from DaimlerChrysler Corporation, Ford Motor Company and General Motors Corporation, along with Secretary of Energy Spencer Abraham, announced a new cooperative automotive research (CAR) partnership between the U.S. Department of Energy and the U.S. Council for Automotive Research (USCAR). The program, FreedomCAR, focuses on developing enabling technologies, such as hydrogen fuel cells, for petroleum-free cars and light trucks.

2003– President George W. Bush announced in his 2003 State of the Union Address a $1.2 billion hydrogen fuel initiative to develop the technology for commercially viable hydrogen powered fuel cells, such that “the first car driven by a child born today could be powered by hydrogen and pollution free.” U.S. Secretary of Energy Spencer Abraham launched the International Partnership for the Hydrogen Economy (IPHE) to foster global cooperation in the development of hydrogen technology.

2004– U.S. Energy Secretary Spencer Abraham announced over $350-million devoted to hydrogen research and vehicle demonstration projects, nearly one-third of President Bush’s commitment. The funding encompasses over 30 lead organizations and more than 100 partners selected through a competitive review process.

______

______

Properties of hydrogen:

Common hydrogen has a molecular weight of 2.016 g/mole. As a gas it has a density of 0.071 g/l at 0ºC and 1 atm. Its relative density, compared with that of the air, is 0.0695. Hydrogen is the most flammable of all the known substances. Hydrogen is slightly more soluble in organic solvents than in water. Many metals absorb hydrogen. Hydrogen absorption by steel can result in brittle steel, which leads to fails in the chemical process equipment.

At normal temperature hydrogen is a not very reactive substance, unless it has been activated somehow; for instance, by an appropriate catalyser. At high temperatures it’s highly reactive.

Although in general its diatomic, molecular hydrogen dissociates into free atoms at high temperatures. Atomic hydrogen is a powerful reductive agent, even at ambient temperature. It reacts with the oxides and chlorides of many metals, like silver, copper, lead, bismuth and mercury, to produce free metals. It reduces some salts to their metallic state, like nitrates, nitrites and sodium and potassium cyanide. It reacts with a number of elements, metals and non-metals, to produce hydrides, like NAH, KH, H2S and PH3. Atomic hydrogen produces hydrogen peroxide, H2O2, with oxygen.

Atomic hydrogen reacts with organic compounds to form a complex mixture of products; with ethylene, C2H4, for instance, the products are ethane, C2H6, and butane, C4H10. The heat released when the hydrogen atoms recombine to form the hydrogen molecules is used to obtain high temperatures in atomic hydrogen welding.

Molecular H2 is unreactive compared to diatomic elements such as halogens or oxygen. The thermodynamic basis of this low reactivity is the very strong H-H bond, with a bond dissociation energy of 435.7 kJ/mol. The kinetic basis of the low reactivity is the nonpolar nature of H2 and its weak polarizability. It spontaneously reacts with chlorine and fluorine to form hydrogen chloride and hydrogen fluoride, respectively. The reactivity of H2 is strongly affected by the presence of metal catalysts. Thus, while mixtures of H2 with O2 or air combust readily when heated to at least 500 C by a spark or flame, they do not react at room temperature in the absence of a catalyst.

Hydrogen has one of the highest energy densities per unit mass (between 120 and 142 MJ/kg), and as it has a higher combustion energy per unit mass than other fuels, it has become of interest to the renewable energy community.

An understanding of the properties of hydrogen is critical for the proper design of a facility or workspace. A workspace can be configured to mitigate hazards by understanding and taking advantage of some of the characteristics of hydrogen.

_

-1. Gaseous Hydrogen

Gaseous hydrogen has some outstanding specifications compared to other fuel types, as can be seen in table below:

|

|

Petrol |

Methane |

Propane |

Hydrogen |

|

Lower explosion limit (%, air) |

15 |

5 |

2,1 |

4 |

|

Upper explosion limit (%, air) |

8 |

15 |

9.5 |

75.6 |

|

Flash point ͦC |

-20 |

-188 |

-104 |

-270.8 |

|

Lowest ignition energy mJ |

0.8 |

0.3 |

0.25 |

0.017 |

|

Density (20 ͦC, 1 bar) |

0.7-0.78 kg/l |

0.718 kg/m3 |

2.01 kg/m3 |

0.089 kg/m3 |

|

Boiling point ͦC |

30-215 |

-161.5 |

-42 |

-252.7 |

|

Critical temperature ͦC |

|

-82.5 |

96.6 |

-239.3 |

|

Critical pressure bar |

|

45 |

42.2 |

13 |

|

Diffusion coefficient cm2/s |

|

0.16 |

0.12 |

0.61 |

Hydrogen is colorless, odorless, tasteless, non-toxic, and non-poisonous. It’s also non-corrosive, but it can embrittle some metals. Hydrogen is the lightest and smallest element and is a gas under atmospheric conditions. Natural gas and propane are also odorless, but industry adds a sulfur-containing odorant so people can detect them. Currently, odorants are not used with hydrogen because there are no known odorants light enough to “travel with” hydrogen at the same dispersion rate. Current odorants also contaminate fuel cells, which are an important application for hydrogen.

Hydrogen is about 57 times lighter than gasoline vapor and 14 times lighter than air. This means that if it is released in an open environment, it will typically rise and disperse rapidly. This is a safety advantage in an outside environment. For indoor applications, it means that hydrogen will concentrate at the ceiling.

Hydrogen is a very small molecule with low viscosity, and therefore prone to leakage. In a confined space, leaking hydrogen can accumulate and reach a flammable concentration. Any gas other than oxygen is an asphyxiant in sufficient concentrations. In a closed environment, leaks of any size are a concern, since hydrogen is impossible for human senses to detect and can ignite over a wide range of concentrations in air. Proper ventilation and the use of detection sensors can mitigate these hazards.

Hydrogen has a high energy content by weight, but not by volume, which is a particular challenge for storage. In order to store sufficient quantities of hydrogen gas, it’s compressed and stored at high pressures. The easiest way to decrease the volume of a gas, at constant temperatures, is to increase its pressure. Thus, at 700 bar, hydrogen has a density of 42 kg/m3, compared to 0.089 kg/m3 under normal pressure and temperature conditions. At this pressure, 5 kg of hydrogen can be stored in a 125 liter tank. For safety, hydrogen tanks are equipped with pressure relief devices that will prevent the pressures in the tanks from becoming too high.

_

-2. Hydrogen Combustion

Hydrogen gas (dihydrogen or molecular hydrogen) is highly flammable:

2 H2(g) + O2(g) → 2 H2O(l) + 572 kJ (286 kJ/mol)

The enthalpy of combustion is −286 kJ/mol.

Hydrogen gas forms explosive mixtures with air in concentrations from 4–74% and with chlorine at 5–95%. The explosive reactions may be triggered by spark, heat, or sunlight. The hydrogen autoignition temperature, the temperature of spontaneous ignition in air, is 500 °C (932 °F). While the flammable limits for a fuel such as natural gas is in the range of 5.0%–15% (gas to air volume ratio), hydrogen has a range from 4.0% to 74.0%. It has a relatively low ignition energy (0.02 milli-Joule). Hydrogen has the smallest ignition energy, much lower than that required for other common fuels. This means that small sparks can easily ignite it.

Hydrogen burns with a pale blue flame that is nearly invisible in daylight, so it is almost impossible to detect by the human senses. Impurities such as sodium from ocean air or other burning materials will introduce color to the hydrogen flame. Both hydrogen and flame detectors are almost always installed with hydrogen systems to quickly identify any leak and minimize the potential for undetected flames. In addition, hydrogen flames radiate little infrared (IR) heat, but substantial ultraviolet (UV) radiation. This means that when someone is very close to a hydrogen flame, there is little sensation of heat, making inadvertent contact with the flame a significant concern. UV overexposure is also a concern, since it can result in sunburn-like effects.

_

If a large hydrogen cloud comes into contact with an ignition source, ignition will likely result in the flame flashing back to the source of the hydrogen. In open spaces with no confinement, flames will propagate through a flammable hydrogen-air cloud at several meters per second, and even more rapidly if the cloud is above ambient temperature. The result is a rapid release of heat, but little overpressure, and the combustion product is steam. It should be noted that hydrogen combustion is more rapid than combustion of other fuels. A hydrogen cloud will burn within seconds, and all of the energy of the cloud will be released. However, a hydrogen gas mixtures ignited in a confined space can generate pressures high enough to rupture equipment, exploding buildings and throw shrapnel. So, keeping hydrogen equipment and piping outdoors is an inherent safety advantage.

A large leak in a pressurized [>1400 kPa (>200 psi)] hydrogen system will result in a jet that may extend for some meters. If ignited, the jet flame can cause serious damage to anything it encounters. This is the reason for establishing separation distances between hydrogen systems and objects that can be harmed by a jet flame.

_

-3. Liquid Hydrogen

Liquid hydrogen has different characteristics and additional potential hazards than gaseous hydrogen, so additional control measures are used to ensure safety. Liquid hydrogen (LH2) is the liquid state of the element hydrogen. To exist as a liquid, H2 must be cooled below its critical point of 33 K. However, for it to be in a fully liquid state at atmospheric pressure, H2 needs to be cooled to 20.28 K (−252.87 °C; −423.17 °F). One common method of obtaining liquid hydrogen involves a compressor resembling a jet engine in both appearance and principle. Liquid hydrogen is typically used as a concentrated form of hydrogen storage. As for any gas, storing it as liquid takes less space than storing it as a gas at normal temperature and pressure. However, the liquid density is very low compared to other common fuels. Once liquefied, it can be maintained as a liquid in pressurized and thermally insulated containers. As a liquid, hydrogen is stored under pressure at around -245°C (-410°F), a temperature that can cause cryogenic burns or lung damage. Detection sensors and personal protective equipment are critical when dealing with a potential liquid hydrogen leak or spill.

The volume ratio of liquid to gas is approximately 1:848. So, if you picture a gallon of liquid hydrogen, that same amount of hydrogen, existing as a gas, would occupy about 848 gallon containers without compression. Hydrogen undergoes a rapid phase change from liquid to gas, so ventilation and pressure relief devices are built into hydrogen systems to ensure safety.

Liquid hydrogen is also colorless. It is extremely cold and only persists if maintained in a cryogenic storage vessel. Storage is usually under pressures up to 1000 kPa (150 psi). If spilled on ambient-temperature surfaces, liquid hydrogen will rapidly boil and its vapors will expand rapidly, increasing 848 times in volume as it warms to room temperatures. If the liquid hydrogen is confined (such as between valves closing off a length of pipe) and left to warm without pressure relief, pressures approaching 170 MPa (25,000 psi) are possible. Confinements will likely rupture under such pressures, producing high-pressure jets of gas and high-speed shrapnel. Ignition is extremely likely under such circumstances.

The density of liquid hydrogen is only 70.85 g/L (at 20 K), a relative density of just 0.07. Although the specific energy is more than twice that of other fuels, this gives it a remarkably low volumetric energy density, many fold lower.

Due to its cold temperatures, liquid hydrogen is a hazard for cold burns. Elemental hydrogen as a liquid is biologically inert and its only human health hazard as a vapor is displacement of oxygen, resulting in asphyxiation. Because of its flammability, liquid hydrogen should be kept away from heat or flame unless ignition is intended.

_

-4. Volumetric density of hydrogen:

-The volumetric density of gaseous hydrogen at atmospheric pressure is 0.09 kg/m³. Consequently, under normal conditions, much space is required to store gaseous hydrogen. Therefore, hydrogen is virtually not stored or transported in gaseous form at atmospheric pressure because it is simply not efficient.

-At a pressure of 350 bar, the volumetric density of gaseous hydrogen is 21 kg/m³. This increased pressure makes it possible to store considerably more gaseous hydrogen in the same space. The pressure of 350 bar is used in the tanks of gaseous hydrogen trucks, for example, the ones from Hyzon. A loaded 55-ton truck needs about 50-70 kg of hydrogen to travel 500 to 600 km.

-At a pressure of 700 bar, the volumetric density of gaseous hydrogen is 42 kg/m³. This relatively high pressure is used, among others, for gaseous hydrogen passenger cars such as the Hyundai NEXO. With a 125 liter tank containing 5 kg of hydrogen, a car can drive about 600 km.

-In liquid form and at a temperature of -252.9 centigrade, hydrogen has a volumetric density of 71 kg/m³. Liquid hydrogen is also used as an energy carrier for sustainable trucks and aircraft, which are currently under development. To drive about 1000 km, a truck needs about 80 kg of liquid hydrogen. This applies, for example, to the liquid hydrogen-powered Daimler GenH2. Liquid hydrogen also offers excellent potential for aircraft because the energy in liquid hydrogen is so high and hydrogen as a fuel is a lot lighter than kerosene. This is a vast advantage for aircraft. However, the volume of liquid hydrogen is a lot more than the volume of kerosene. To carry the same amount of total energy on board, you need four times the volume of liquid hydrogen compared to kerosene. Fortunately, there are ways to use fuel efficiently. For example, fuel cells are more efficient than fuel engines, and superconductivity makes them even more economical. By applying these techniques, it is not always necessary to take a massive amount of hydrogen on board.

______

Isotopes of hydrogen:

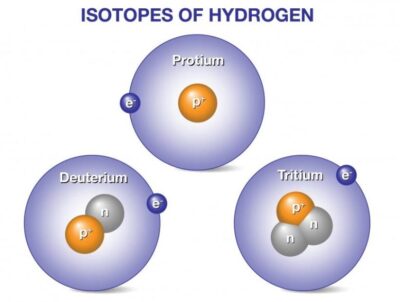

Hydrogen has three naturally occurring isotopes, denoted 1H, 2H and 3H. Other, highly unstable nuclei (4H to 7H) have been synthesized in the laboratory but not observed in nature.

Deuterium and tritium are isotopes of hydrogen, the most abundant element in the universe. Whereas all isotopes of hydrogen have one proton, deuterium also has one neutron and tritium has two neutrons, so their ion masses are heavier than protium, the isotope of hydrogen with no neutrons.

1H is the most common hydrogen isotope, with an abundance of more than 99.98%. Because the nucleus of this isotope consists of only a single proton, it is given the descriptive but rarely used formal name protium. It is unique among all stable isotopes in having no neutrons.

2H, the other stable hydrogen isotope, is known as deuterium and contains one proton and one neutron in the nucleus. All deuterium in the universe is thought to have been produced at the time of the Big Bang, and has endured since that time. Deuterium is not radioactive, and does not represent a significant toxicity hazard. Water enriched in molecules that include deuterium instead of normal hydrogen is called heavy water. Water made from deuterium is about 10 percent heavier than ordinary water. It will actually sink to the bottom of a glass of ordinary water. Deuterium and its compounds are used as a non-radioactive label in chemical experiments and in solvents for 1H-NMR spectroscopy. Heavy water is used as a neutron moderator and coolant for nuclear reactors. Deuterium is also a potential fuel for commercial nuclear fusion.

3H is known as tritium and contains one proton and two neutrons in its nucleus. It is radioactive, decaying into helium-3 through beta decay with a half-life of 12.32 years. Tritium is rare in nature. Exposing the more abundant element of lithium to energetic neutrons can generate tritium. It is so radioactive that it can be used in luminous paint, making it useful in such things as watches. The glass prevents the small amount of radiation from getting out. Small amounts of tritium are produced naturally by the interaction of cosmic rays with atmospheric gases; tritium has also been released during nuclear weapons tests. It is used in nuclear fusion reactions, as a tracer in isotope geochemistry, and in specialized self-powered lighting devices. Tritium has also been used in chemical and biological labeling experiments as a radiolabel.

_

When deuterium and tritium fuse, they create a helium nucleus, which has two protons and two neutrons. The reaction releases an energetic neutron. Fusion power plants would convert energy released from fusion reactions into electricity to power our homes, businesses, and other needs. Fortunately, deuterium is common. About 1 out of every 5,000 hydrogen atoms in seawater is in the form of deuterium. This means our oceans contain many tons of deuterium. When fusion power becomes a reality, just one gallon of seawater could produce as much energy as 300 gallons of gasoline. A working fusion power plant would need enriched lithium to breed the tritium it needs to close the deuterium-tritium fuel cycle. Current R&D efforts are focused on advanced designs of tritium breeding blankets using lithium originally obtained from Earth based sources. To avoid certain R&D challenges including structural material damage from energetic neutrons, fusion scientists are interested also in aneutronic fusion reactions (such as deuterium-helium-3 and proton-boron fusion) even though these fusion reactions occur at higher ion temperatures than for deuterium and tritium. Hydrogen would become energy source when commercial nuclear fusion power generation becomes reality.

______

Spin isomers of hydrogen:

A molecule of dihydrogen contains two atoms, in which the nuclei of both the atoms are spinning. Depending upon the direction of the spin of the nuclei, the hydrogens are of two types:

Ortho hydrogen molecules are those in which the spins of both the nuclei are in the same direction. Molecules of hydrogen in which the spins of both the nuclei are in the opposite direction are called para hydrogen. Ordinary dihydrogen is an equilibrium mixture of ortho and para hydrogen.

The amount of ortho and para hydrogen varies with temperature as:

-At 0°K, hydrogen contains mainly para hydrogen which is more stable.

-Liquid hydrogen consists of 99.79% parahydrogen and 0.21% orthohydrogen.

-At the room temperature, the ratio of ortho to para hydrogen is 3:1.

-Even at very high temperatures, the ratio of ortho to para hydrogen can never be more than 3:1.

Thus, it has been possible to get pure para hydrogen by cooling ordinary hydrogen to a very low temperature (close to 20 K) in liquid form but it is never possible to get a sample of hydrogen containing more than 75% of ortho hydrogen.

At room temperature, gaseous hydrogen is mostly in the ortho isomeric form due to thermal energy, but an ortho-enriched mixture is only metastable when liquified at low temperature. It slowly undergoes an exothermic reaction to become the para isomer, with enough energy released as heat to cause some of the liquid to boil. To prevent loss of the liquid during long-term storage, it is therefore intentionally converted to the para isomer as part of the production process, typically using a catalyst such as iron(III) oxide, activated carbon, platinized asbestos, rare earth metals, uranium compounds, chromium(III) oxide, or some nickel compounds. If orthohydrogen is not removed from rapidly liquified hydrogen, without a catalyst, the heat released during its decay can boil off as much as 50% of the original liquid.

_______

Cosmic prevalence and distribution:

Hydrogen, as atomic H, is the most abundant chemical element in the universe, making up 75 percent of normal matter by mass and more than 90 percent by number of atoms. (Most of the mass of the universe, however, is not in the form of chemical-element type matter, but rather is postulated to occur as yet-undetected forms of mass such as dark matter and dark energy.) This element is found in great abundance in stars and gas giant planets. Molecular clouds of H2 are associated with star formation. Hydrogen plays a vital role in powering stars through the proton-proton reaction in case of stars with very low to approximately 1 mass of the Sun and the CNO cycle of nuclear fusion in case of stars more massive than our Sun.

States of hydrogen:

Throughout the universe, hydrogen is mostly found in the atomic and plasma states, with properties quite distinct from those of molecular hydrogen. As a plasma, hydrogen’s electron and proton are not bound together, resulting in very high electrical conductivity and high emissivity (producing the light from the Sun and other stars). The charged particles are highly influenced by magnetic and electric fields. For example, in the solar wind they interact with the Earth’s magnetosphere giving rise to Birkeland currents and the aurora. Hydrogen is found in the neutral atomic state in the interstellar medium because the atoms seldom collide and combine. They are the source of the 21-cm hydrogen line at 1420 MHz that is detected in order to probe primordial hydrogen.

Under ordinary conditions on Earth, elemental hydrogen exists as the diatomic gas, H2. Hydrogen gas is very rare in the Earth’s atmosphere (1 ppm by volume) because of its light weight, which enables it to escape from the atmosphere more rapidly than heavier gases. However, hydrogen is the third most abundant element on the Earth’s surface, mostly in the form of chemical compounds such as hydrocarbons and water. The discoveries of hundreds of natural H2 seepages, generally connected with circulation of hydrothermal fluids through ultramafic rocks, both under the seafloors and on the continents, raise important questions regarding the energy potential that these sources can represent. Much has been learned about natural hydrogen (H2) seepages and accumulation, but present knowledge of hydrogen behavior in the crust is so limited that it is not yet possible to consider exploitation of this resources.

A molecular form called protonated molecular hydrogen ((H+3) is found in the interstellar medium, where it is generated by ionization of molecular hydrogen from cosmic rays. This ion has also been observed in the upper atmosphere of the planet Jupiter. The ion is relatively stable in the environment of outer space due to the low temperature and density. H+3 is one of the most abundant ions in the universe, and it plays a notable role in the chemistry of the interstellar medium. Neutral triatomic hydrogen H3 can exist only in an excited form and is unstable. By contrast, the positive hydrogen molecular ion (H+2) is a rare molecule in the universe.

_______

_______

The challenge of cutting carbon:

The atmosphere contains greenhouse gases, of which CO2, CH4, N2O and H2O are the primary ones. These gases permit the radiation of the sun to reach the surface of the earth while simultaneously preserving part of the heat that radiates from the earth within the atmosphere. This is called the greenhouse effect. In the same way that the glass in a greenhouse prevents the loss of heat, the greenhouse gases prevent the total escape of heat from the earth’s surface to outer space. Without these gases the average temperature on the earth would be about 35 degrees lower than it is today (in other words, a temperature of about –20 degrees Celsius).

_

The releases of fossil CO2 disturb a naturally renewable balance, already unbalanced by the activities of mankind through the cutting and burning of forest and vegetation at a more rapid pace than it is replanted and regrown. In other words, more CO2 is released (through the burning of wood and so on) than the plants are able to take up through photosynthesis. Furthermore, dead biological material (paper, food leftovers, textiles) are left to rot without the presence of oxygen, thereby resulting in a conversion to the climate gas methane (CH4) rather than CO2. Methane’s greenhouse effect is a factor of 21 times higher than that of CO2. In addition, new chemicals (for example, chlorofluorocarbon gases) have been introduced that also remain in the atmosphere and contribute towards intensifying the greenhouse effect.

_

The amount of the various gases in the atmosphere have varied throughout the earth’s history due to volcano eruptions and other natural phenomena. However, over the course of the last two hundred years, mankind has made an ever-increasing impact on the makeup of these atmospheric gases. We are disturbing the natural CO2 cycle to a steadily increasing degree. In the course of a few short decades, we have extracted, refined and consumed fossil material that the earth has used millions of years to produce, releasing large amounts of carbon dioxide. Nature partly manages to absorb the ”fossil” CO2 gas by binding it in the sea and in plants through the process of photosynthesis, but large amounts nonetheless end up in the atmosphere.

_

As the chart above shows, the current greenhouse gas trajectory will far exceed the global warming limits set by the Paris Agreement. Countries across the globe adopted an historic international climate agreement at the UN Framework Convention on Climate Change (UNFCCC) Conference of the Parties (COP21) in Paris in December 2015. In anticipation of this moment, countries publicly outlined what post-2020 climate actions they intended to take under the new international agreement, known as their Intended Nationally Determined Contributions (INDCs). The climate actions communicated in these INDCs largely determine whether the world achieves the long-term goals of the Paris Agreement: to hold the increase in global average temperature to well below 2°C, to pursue efforts to limit the increase to 1.5°C, and to achieve net zero emissions in the second half of this century. The transition to renewables depends on new energy technologies being scaled-up to provide workable substitutes for our dependence on fossil fuels.

_

All nations wish to tackle climate change. Many have very strong policies focused on green electricity, at both the national and regional level. California just announced that it is aiming to achieve 100% green electricity on its network by 2045. Europe will reach 30% by 2020 and is aiming for 50% by 2030. Electricity, however, represents less than a quarter of energy use in Europe. Around half of total energy use is for heating, which is mainly covered by natural gas. The other big part is transport, which represents a third of the total, and is mainly covered by liquid fuels.

One can argue that biomass and biogas help decarbonise heating in Europe (covering 19% of total heating needs) and biofuels help decarbonise transport in Europe (with 7% of the total). But we still face three major facts about Europe, which are true of other regions too.

-1. Greening electricity networks is great and should be further encouraged but even if half our electricity was produced by renewables, we would still only decarbonise about 10% of the energy we use. As 80% of worldwide CO2 emissions are related to energy, it is key that we understand where to put the emphasis in order to reduce them faster.

-2. Heating and transport, which represent 75% of our energy needs, are mainly covered by solid, gas and liquid fuels, which are emitting CO2 (even biomass, biogas and biofuels). And we know that if we do not want to warm up the planet by more than 2°C, we cannot release more CO2 than we did between 1985 and today. So, it is only if we have major CO2 sinks (such as large forests and carbon capture and storage sites) that we can expect to cope with this reality. If not, we need to look for a substitute to these fuels which does not emit CO2.

-3. Increasing green electricity levels on the grid leads to major instabilities due to the intermittent nature of solar and wind resources. We therefore need to find ways to store these electrons on a massive scale for later use. Battery-based large storage exists, but it fills up very quickly and is best for storing and releasing electricity within a day, not for long-term storage.

_

Green hydrogen offers a solution:

It is the only gas that does not contain any carbon, and so using it for heating and transport does not generate any CO2 – only water. Generating it from green power helps store it and balance the grid.

On the heating side, green hydrogen can be mixed up to 20% with natural gas in pipelines, or dedicated pure hydrogen pipelines can be laid (there are several thousands of kilometres of them around the world already). It can then be used in existing gas appliances or dedicated fuel cells to generate heat and power.

On the transport side, hydrogen can power fuel cell-based vehicles, such as electric vehicles carrying a hydrogen tank and a fuel cell that transforms on-demand hydrogen into electrons to power the car.

Green hydrogen is set to enter industrial processes, mobility, homes, buildings and cities. As such, we must ask ourselves how it will impact our activities as it develops into a new energy source, and much sooner and faster than initially thought.

_

Green Goals:

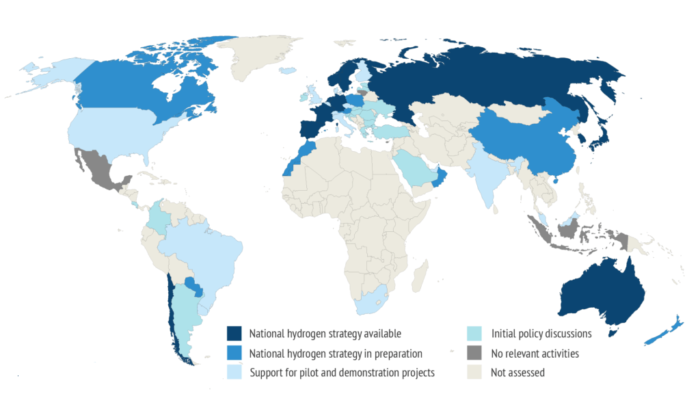

Many more countries have announced full hydrogen strategies in 2020

Hydrogen could be used to meet 27% of Canada’s primary energy needs

The Nord Stream 2 gas pipeline could deliver hydrogen from Russia to Europe

EU aims to install 40GW of renewable hydrogen electrolyzers by 2030

Japan was the first to adopt a comprehensive hydrogen strategy

Germany’s $10B strategy outspends the rest

South Korea wants to lead in the production and use of hydrogen vehicles

China is already the world’s largest producer, but mostly from coal

Australia aims to be among the top three exporters of hydrogen to Asian markets by 2030

Chile aims to produce the world’s cheapest green hydrogen by 2030.

_______

_______

Section-3

Energy and fuel:

_

The energy challenge:

Energy is the most important need for the human life and development worldwide. Energy is a topical subject in our daily life. The rapid growth of population and increase of personal income are the key drivers behind growing energy demand. It is projected that by 2035, an additional 1.6 billion people will demand energy when the global population reaches 8.7 billion. The major problem faced is the conflict between increasing energy demand and the scarceness of existing fossil fuel supply, together with concerns associated with the utilisation of conventional fossil fuels, such as greenhouse gas emissions leading to climate change, as well as the negative impact on human health from other associated pollutants.

There is an urgent need to source clean alternative and sustainable fuel to replace existing non-renewable fossil fuels. The world has seen a rapid growth in the development of renewable power generation. However, there are numerous disadvantages inherent in renewable power plants. Typically, renewable power plants are far away from the demand site, as a result, the transport of renewable energy presents a difficulty. The inherent intermittent nature and fluctuation of renewable power sources indicate that the power generation is unpredictable and there is an inevitable mismatch between the renewable power generation and the load demand. Hence, with existing centralised power generation and distribution networks, increasing decentralised renewable power plants, like PV arrays and wind farms, will have significant impact on the stability of the grid. As a result, curtailment is a mechanism currently used to solve those problems which is expensive and prevents the further penetration of renewable power. Curtailment is the reduction of output of a renewable resource below what it could have otherwise produced. Curtailment is permitted on grounds of maintaining grid stability and system safety. Energy storage is a solution to address the aforementioned problems. Among various energy storage mechanisms, such as pumped hydro, battery, compressed air, flywheels, capacitor, and others, hydrogen is a promising candidate to help construct our future energy system.

Energy security is a major issue. Fossil fuel, particularly crude oil, is confined to a few areas of the world and continuity of supply is governed by political, economic and ecological factors. These factors conspire to force volatile, often high fuel prices while, at the same time, environmental policy is demanding a reduction in greenhouse gases and toxic emissions.

A coherent energy strategy is required, addressing both energy supply and demand, taking account of the whole energy lifecycle including fuel production, transmission and distribution, and energy conversion, and the impact on energy equipment manufacturers and the end-users of energy systems. In the short term, the aim should be to achieve higher energy efficiency and increased supply from renewables. In view of technological developments, vehicle and component manufacturers, transport providers, the energy industry, and even householders are seriously looking at alternative energy sources and fuels and more efficient and cleaner technologies – especially hydrogen and hydrogen-powered fuel cells. In the long term, a hydrogen-based economy will have an impact on all these sectors.

_

Fuel:

A fuel is any material that can be made to react with other substances so that it releases energy as heat energy or to be used for work. The main purpose of fuel is to store energy, which should be in a stable form and can be easily transported to the place of use. Almost all fuels are chemical fuels. The user employs this fuel to generate heat or perform mechanical work, such as powering an engine. It may also be used to generate electricity, which is then used for heating, lighting, or other purposes.

Alternative fuel, known as non-conventional and advanced fuels, are any materials or substances that can be used as fuels, other than conventional fuels like; fossil fuels (petroleum oil, coal, and natural gas), as well as nuclear materials such as uranium and thorium, as well as artificial radioisotope fuels that are made in nuclear reactors.

Some well-known alternative fuels include bio-diesel, bio-alcohol (methanol, ethanol, butane), refuse-derived fuel, chemically stored electricity (batteries and fuel cells), hydrogen, non-fossil methane, non-fossil natural gas, vegetable oil, propane and other biomass sources.

_

Hydrogen as an Alternative Fuel:

Hydrogen is considered an alternative fuel under the Energy Policy Act of 1992 of the US. The interest in hydrogen as an alternative transportation fuel stems from its ability to power fuel cells in zero-emission vehicles, its potential for domestic production, and the fuel cell’s fast filling time and high efficiency. In fact, a fuel cell coupled with an electric motor is two to three times more efficient than an internal combustion engine running on gasoline. Hydrogen can also serve as fuel for internal combustion engines. However, unlike FCEVs, these produce tailpipe emissions and are less efficient.

It takes more energy to produce hydrogen (by separating it from other elements in molecules) than hydrogen provides when it is converted to useful energy. However, hydrogen is useful as an energy source/fuel because it has a high energy content per unit of weight, which is why it is used as a rocket fuel and in fuel cells to produce electricity on some spacecraft. Hydrogen is not widely used as a fuel now, but it has the potential for greater use in the future.

_

The hydrogen atom is the lightest, simplest and most common element in the universe. However, it occurs only in combination with other elements, primarily with oxygen in water and with carbon, nitrogen and oxygen in living materials and fossil fuels. Hydrogen is not a primary source of energy. However, it becomes an attractive energy carrier when split from these other elements by using a source of energy. Hydrogen, as clean energy carrier, is considered to be the clean fuel of future particularly for energy storage and transport. The energy storage capacity of hydrogen is excellent because calculations show that one kilogram of hydrogen contains approximately 33 kWh of usable energy.

The advantages of hydrogen are: (i) energy security by reducing oil imports, (ii) sustainability by taking advantage of the RE sources, (iii) less pollution and better urban air quality by producing near-zero carbon, hydrocarbon, GHG and NOx emissions at the point of use, and (iv) economic viability by potentially shaping the future global energy markets. Therefore, Hydrogen is a worldwide-accepted clean energy carrier as it is source-independent and has a high energy content per mass compared to petroleum as listed in Table below. Although there are some nitrogen oxides produced during high temperature combustion, environmental pollutant can be fully removed during low temperature utilization such as by fuel cells.

Comparison between Hydrogen and different fuel as source of energy:

|

Fuel |

Energy content (MJ/kg) |

|

Hydrogen |

120 |

|

Liquefied natural gas |

54.4 |

|

Propane |

49.6 |

|

Aviation gasoline |

46.8 |

|

Automotive gasoline |

46.4 |

|

Automotive diesel |

45.6 |

|

Ethanol |

29.6 |

|

Methanol |

19.7 |

|

Coke |

27 |

|

Wood(dry) |

16.2 |

|

Begasse |

9.6 |

_

What makes hydrogen more powerful than gasoline?

The simplicity of hydrogen (two hydrogen atoms held together in a single H-H bond) makes for very fast rates of energy release, or rapid kinetics. Compare this to octane, a primary constituent of gasoline, which has 25 chemical bonds per molecule (7 carbon-carbon and 18 carbon-hydrogen bonds). This not only bodes well for hydrogen’s use in conventional combustion, but it also opens its use in high-efficiency electrochemical energy transformers, such as fuel cells. The electrochemical option is estimated to offer more than twice the fuel economy of an internal combustion engine-based powertrain while producing no polluting emissions.

_

Gasoline, which is derived from refining crude oil, contains much more energy than coal (twice the lower grade bituminous) or wood (three times). Liquid natural gas (LNG) is almost entirely composed of methane, while natural gas has about 85% of its mass accounted by methane. Jet A-1 is the standard fuel used by commercial jet planes and is mostly composed of kerosene and several additives (antifreeze, antioxidant and antistatic) since the fuel must meet rigorous specifications as it will be exposed to high altitudes and low temperatures. Conversely, Bunker C fuel, which is the primary fuel used for maritime shipping, can be considered one of the lowest quality fuels in liquid form but suitable for the vast ship engines.

The energy in 2.2 pounds (1 kilogram) of hydrogen gas is about the same as the energy in 1 gallon (6.2 pounds, 2.8 kilograms) of gasoline. No matter how it is used, the by-product the burning of hydrogen is water. The World Energy Council (WEC) says that “combusting one kilo of hydrogen releases three times more energy than a kilo of gasoline and produces only water”. Then, there are hydrogen fuel cells, which is “an electrochemical cell that converts the chemical energy of hydrogen and oxygen into electricity”, whose waste product, again, is water. “Fuel cells can produce electricity continuously for as long as hydrogen and oxygen are supplied,” WEC says. Because hydrogen has a low volumetric energy density, it is stored onboard a vehicle as a compressed gas to achieve the driving range of conventional vehicles. Most current applications use high-pressure tanks capable of storing hydrogen at either 5,000 or 10,000 pounds per square inch (psi), that is 350 to 700 bar. For example, the FCEVs in production by automotive manufacturers and available at dealerships have 10,000 psi tanks. Retail dispensers, which are mostly co-located at gasoline stations, can fill these tanks in about 5 minutes. Fuel cell electric buses currently use 5,000 psi tanks that take 10–15 minutes to fill. Other ways of storing hydrogen are under development, including bonding hydrogen chemically with a material such as metal hydride or low-temperature sorbent materials.

_

Hydrogen is often advocated as an energy carrier. Here are some relevant facts.

Energy carriers allow the transport of energy in a usable form from one place to another. Hydrogen, like electricity, is an energy carrier that must be produced from another substance. Hydrogen can be produced—separated—from a variety of sources including water, fossil fuels, or biomass and used as a source of energy or fuel.

-1. Hydrogen is the lightest of the elements with an atomic weight of 1.0. Liquid hydrogen has a density of 0.07 grams per cubic centimeter, whereas water has a density of 1.0 g/cc and gasoline about 0.75 g/cc. These facts give hydrogen both advantages and disadvantages. The advantage is that it stores approximately 2.6 times the energy per unit mass as gasoline, and the disadvantage is that it needs about 4 times the volume for a given amount of energy. A 15 gallon automobile gasoline tank contains 90 pounds of gasoline. The corresponding liquid hydrogen tank would be 60 gallons, but the hydrogen would weigh only 34 pounds.

-2. When hydrogen is burned in air the main product is water. Some nitrogen compounds may also be produced and may have to be controlled. Should greenhouse warming turn out to be an important problem, the key advantage of hydrogen is that carbon dioxide (CO2) is not produced when hydrogen is burned.

-3. Since hydrogen is not available in significant quantities in nature in pure form, the main present way of getting hydrogen is steam methane reforming, and this will probably remain the most economical way as long as methane (natural gas) is available cheaply and in large quantities, and hydrogen is required only in small quantities. When the price of methane goes up to more than three times its present price because of scarcity, hydrogen will be obtained by splitting water H2O into hydrogen H2 and oxygen O2.

The chemical reaction is written 2H2O + energy => 2H2 + O2.

The well developed way of splitting water is by electrolysis. If fossil fuels, e.g., coal, oil or natural gas, are used to generate the electricity, there is no advantage over using the fossil fuels directly. Indeed you still get all the CO2, and there is a considerable loss of energy. Therefore, the large scale use of hydrogen depends on using either nuclear or solar electricity. The law of conservation of energy tells us that all the energy to be obtained by burning the hydrogen must be supplied by the primary source, e.g. nuclear or solar. Of course, since these processes aren’t 100 percent efficient, there is some loss of energy. Therefore, the use of hydrogen as an intermediate is justified only when there is some reason not to use the primary source directly. For vehicles the reason is that both nuclear nor solar power plants are too big to carry around, except that nuclear power is suitable for large ships.

-4. If there is large scale use of solar energy, the energy is likely to be generated far from where it is used and at a different time. Hydrogen has been proposed as both a storage and transmission medium. It should work for these purposes. Hydrogen can be transported by pipelines similar to those used to transport natural gas. There are some additional problems, because hydrogen tends to leak more and can embrittle some metals used for pipelines. The existence of a 240 km hydrogen pipeline in Germany operated by the company Air Liquide provides evidence that these difficulties can be overcome. There is also 879 km hydrogen pipeline network in Belgium, France, and the Netherlands operated by Air Liquide.

______

______

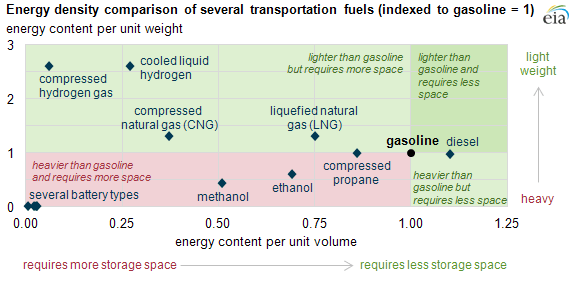

Hydrogen energy density:

Different fuels have different energy density levels (see figure below), which can be measured in terms of equivalent energy released through combustion. Energy density is the amount of energy that can be released by a given mass or volume of fuel. It can be measured in terms of gravimetric energy density (per unit of mass) or volumetric energy density (per unit of volume). Gravimetric energy density is relevant when comparing the energy efficiency of fuels. At the same time, volumetric energy density is relevant when comparing transportation modes as storage space must be present to carry the fuel propelling a vehicle. The higher the energy density, the higher the fuel quality, which is inversely proportional to its chemical complexity. High-quality fuels are gases, while low-quality fuels are solids, with liquids in between. The highest energy density fuel is hydrogen, which is also the simplest chemical component in existence.

_

The gas weighs almost nothing but has an extremely high gravimetric energy density. One kilogram of hydrogen contains a vast amount of energy, making it an efficient and lightweight energy carrier. In turn, the volumetric energy density of hydrogen is particularly low. Per volume, the energy content of hydrogen is even a lot lower than that of most other fuels and energy carriers. Consequently, storing or using hydrogen at atmospheric pressure and temperature requires a substantial amount of space. Fortunately, there is a solution to this. By compressing or liquefying hydrogen, it is possible to raise the low volumetric energy density. This makes the storage, transportation, and application of hydrogen considerably easier.

|

Results from various sources |

||||||||||||||||||||

|

||||||||||||||||||||

|

||||||||||||||||||||

|

||||||||||||||||||||

|

||||||||||||||||||||

|

Fuel and storage method energy densities |

||||||||||||||||||||

_

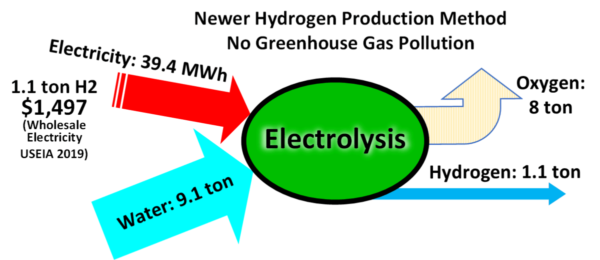

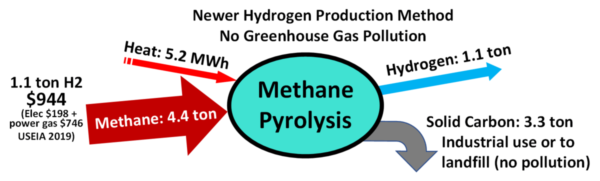

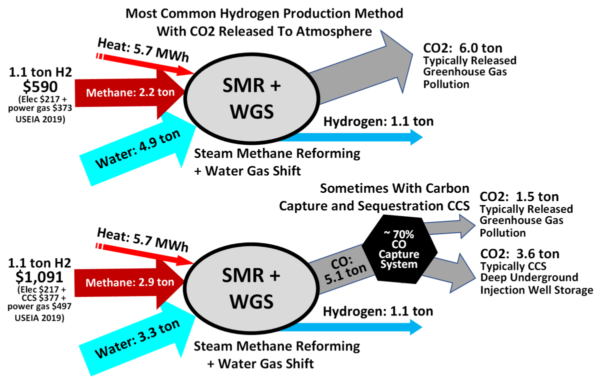

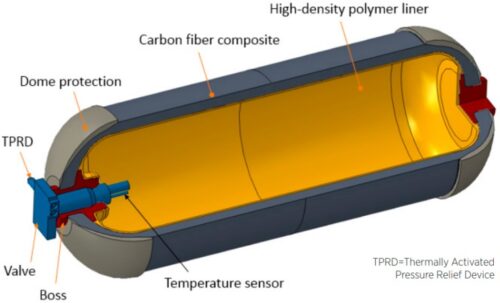

At any pressure, hydrogen gas clearly carries less energy per volume than methane (representing natural gas), methanol, propane or octane (representing gasoline). At 800 bar pressure gaseous hydrogen reaches the volumetric energy density of liquid hydrogen. But at any pressure, the volumetric energy density of methane gas exceeds that of hydrogen gas by a factor of 3.2. The common liquid energy carriers like methanol, propane and octane (gasoline) surpass liquid hydrogen by factors 1.8 to 3.4, respectively. But at 800 bar or in the liquid state hydrogen must be contained in hi-tech pressure tanks or in cryogenic containers, while the liquid fuels are kept under atmospheric conditions in unsophisticated containers.