Dr Rajiv Desai

An Educational Blog

DERAILMENT

DERAILMENT:

_______

_______

Prologue:

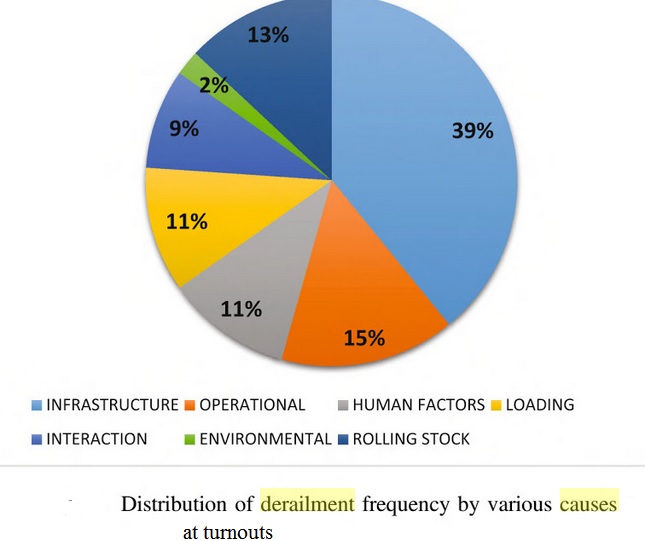

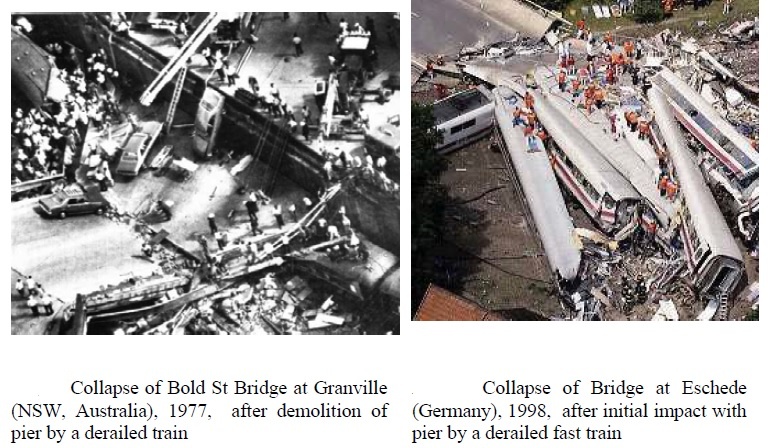

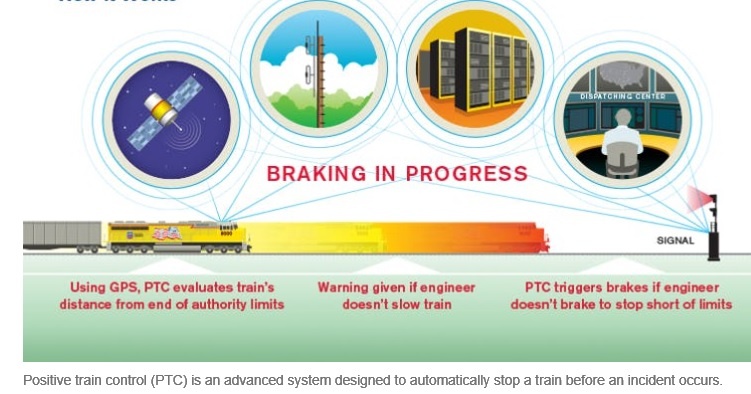

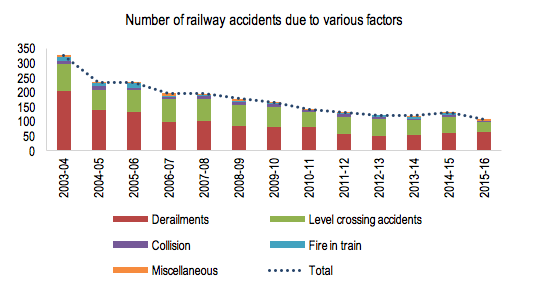

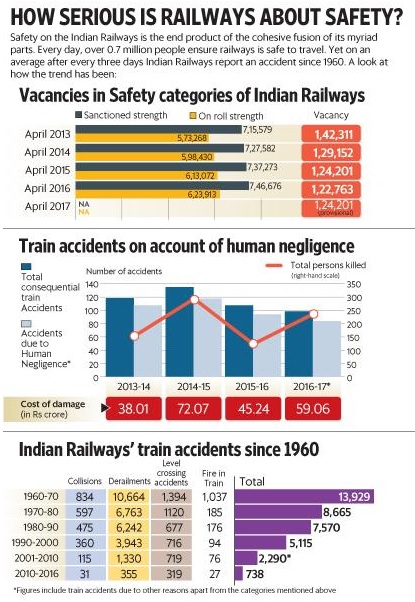

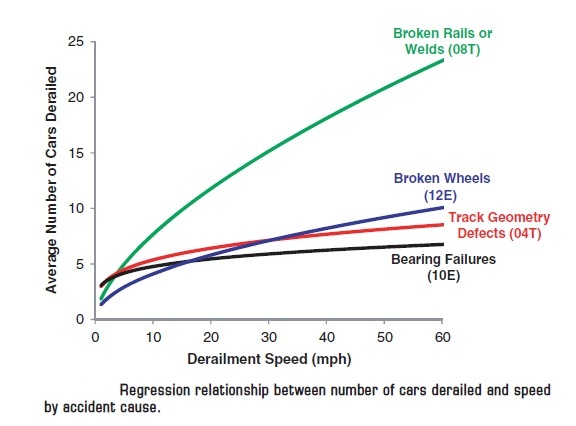

A tremor was followed by a “loud sound like an earthquake”. The carriages began to shake and inside them, passengers began falling on each other. Some carriages telescoped into each other, others rose vertically, “almost standing upright”. In a major train derailment accident, at least 23 passengers were killed and over 60 injured when 14 coaches of the Puri-Haridwar Utkal Express jumped the rails in Khatauli, India at 5.45 pm on19 August 2017 as seen in the figure above. Indian Railways has had the most derailments in a decade in 2016-17: 78 derailments with 193 people dead. On September 14, 2017 (coincidentally my birthday) Indian Prime Minister Narendra Modi and Japanese Prime Minister Shinzo Abe laid the foundation stone for $17 billion bullet train, the Jammu Tawi-New Delhi Rajdhani Express jumped the tracks at New Delhi station, the ninth derailment in 27 days, a consequence of growing traffic, falling safety standards and under investment. Many people say that Indian railways first need to ensure that passengers complete their journeys alive and the money would be better spent upgrading ageing carriages and crumbling tracks. The construction of railways is developing rapidly and the train is going faster and faster, so how to control and prevent derailment of train has become one of the most important task for people working in railways. Train derailments can mainly result in not only financial losses in the form of damaged rolling stock and infrastructure, but also more importantly in causalities and operational shut-down. Therefore, it is crucial for the railway industry to sustain a reliable and efficient operation and eliminate safety concerns. According to the theory of accident causation by Heinrich, behind the seemingly accidental incident is the inevitable rule: to draw a lesson from the accident, and to avoid the similar accident from happening again. Analysis of accidents caused by train derailment is highlighted as one of the most crucial steps in the risk management chain. Considering various operational environment, the analysis enables reduction in the occurrence of derailment and prevents derailments in the most cost-efficient manner, as a variety of different causes and their frequency and severity are determined. A paper written in 2012 analyzing data from the previous decade showed that “broken rails or welds were the leading derailment cause on main, yard, and siding tracks.” Other possible causes can include human error: going too fast, using the wrong track switch, or mistakes with the brakes. Although the railways keep our 21st-century economy running, it’s essentially a 19th-century technology. Rail operators have known for decades that technological fixes could prevent rail disasters but they have been dragging their feet because those fixes are expensive and complicated. I have always preferred train travel to air or road travel but recent epidemic of derailments raises concern in my mind.

______

______

Train wheels on rail track:

_

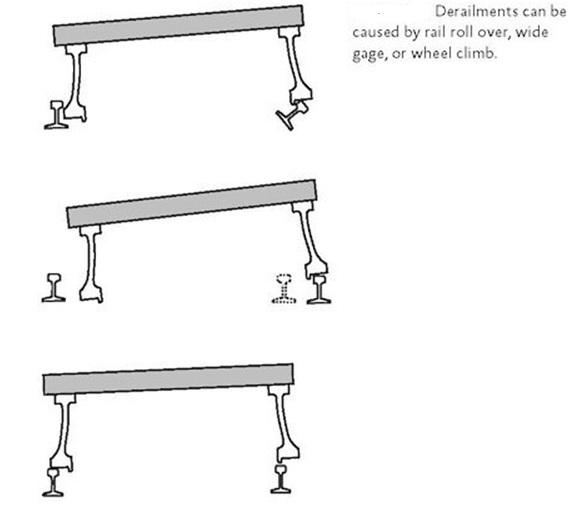

Train wheels off rail track = derailment:

______

______

Abbreviations and synonyms:

Railroad = Railways

Switch = Point = Turnout

Railroad car = railcar = car = wagon = carriage = coach

Bogie = railroad truck = truck = chassis or framework-like structure underneath a train to which axles and wheels are attached through bearings. In India, railway coach is also known as bogie.

Rake = group of coaches or wagons

Locomotive = railway engine

_

C.G. = center of gravity

CWR = Continuous welded rail

SPAD = Signal Passed at Danger

HABD = Hot Axle Box Detectors

RCF = Rolling contact fatigue

RCW = Rolling contact wear

LC = Level crossings

GRS = Guard rail system

LHB = Linke Hofmann Busch

ICF = Integral Coach Factory

PTC = Positive Train Control

AWS = Automatic Warning System

TPWS = Train Protection & Warning System

ATP = Automatic train protection

ACD = Anti-collision device

TCAS = Train Collision Avoidance System

ETCS = European Train Control System

HSR = High speed rail

FRA = Federal Railroad Administration

BG = Broad Gauge

SG = Standard Gauge

MG = Meter Gauge

NG = Narrow Gauge

WSP = Wheel Slide Protection

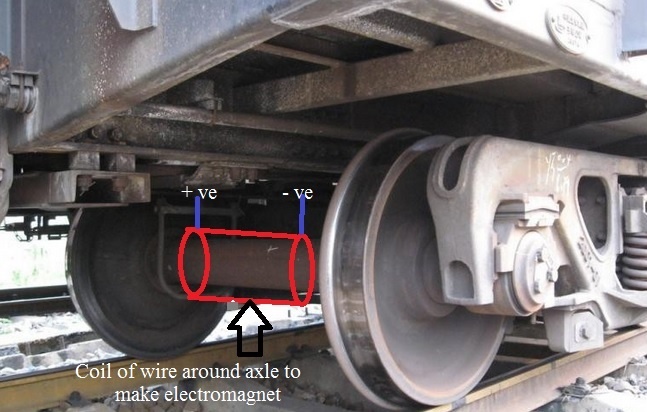

ACE = Axle Core Electromagnet

______

______

Introduction to railways:

_

History of railways from horse-driven carriages to high speed train:

_

Chugging across short distances or entire continents, trains act as a major form of transportation worldwide. Also called railroads or railways, trains carry within their cars passengers or freight — such as raw materials, supplies or finished goods — and sometimes both. Before you had limited options for traveling around town and country. Paved roadways didn’t always crisscross the countryside. Even with roads, horse-drawn vehicles still struggled to move people and goods, especially in bad weather. As early as 1550, pragmatic Germans constructed and used wooden railway systems, reasoning that horse-drawn wagons and carts could travel more easily and quickly over wooden rails than dirt roads. By the late 1700s, iron wheels and rails had one-upped wooden ones. But it wasn’t until the steam locomotive was invented in 1797 in England that the railroad as we know it began to take shape. The history of railroading is rooted in the production of the first metal rails near the city of Sheffield, England in 1776. The rail improved the transportation of materials in industries such as mining. In 1803 the first railroad intended for public use was opened for operation between the London docks and Croyden. This first railway, the Surrey Iron Railway, offered a smoother ride than a wagon, but offered no real advantage in speed since draft animals were used for locomotion. However, the first steam locomotive was soon to arrive on the scene. In 1804, a steam locomotive pulled a train of cars carrying several tons of ore for the iron works at Merthyr Tydfil in South Wales. The first American locomotive, the Best Friend of Charleston, was placed in operation on the South Carolina Railroad in 1831. The Stockton & Darlington Railroad Company in England became the first public railroad to carry passengers and freight. Steam-powered locomotives carried six coal cars and up to 450 passengers a distance of 9 miles (14 kilometers) in less than an hour. Horses just couldn’t top that. Across the ocean, the B&O Railroad Company established itself as the first U.S. railroad company in 1827. By 1860, U.S. rail workers had laid more than 30,000 miles (48,280 kilometers) of track, more than in the entire world. Railroads served as the main mode of transportation and made it cheap and easy to ship supplies and goods, even for Union and Confederate armies during the Civil War. After the Civil War, the U.S. railroad network expanded again, and the country’s first transcontinental railway was completed in 1869. Towns sprouted along the railway lines, and the railroad hastened westward expansion. By the early 20th century, U.S. railroads operated 254,000 miles (408,773 kilometers) of track. Diesel locomotives had replaced steam ones. But by the mid-20th century, the decline of the U.S. railroads had begun. A developed interstate highway system and extensive federal regulations took their toll on trains. In the ongoing energy crisis, however, trains, which run on diesel and sometimes even biodiesel fuel, may regain their former popularity with passengers as we move through the 21st century. When we say train, we’re referring to the whole package: railroad cars, railroad track, switches, signals and a locomotive, although not all trains rely on locomotives to pull them, but most of the trains do. With the locomotives leading the way, coupled-together railroad cars follow, filled with freight and passengers. The railroad track steers the train.

____

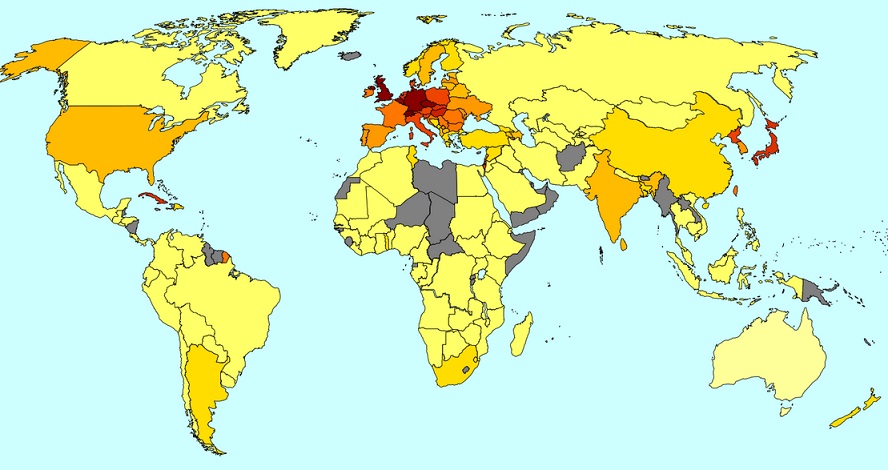

Figure below shows worldwide rail network density:

_______

_______

Train:

The railway terminology that is used to describe a train varies between countries.

Rolling stock is any railway vehicle that is not capable of moving under its own power in UK and any railroad car or locomotive in US.

United Kingdom:

In the United Kingdom, the interchangeable terms set and unit are used to refer to a group of permanently or semi-permanently coupled vehicles, such as those of a multiple unit. While when referring to a train made up of a variety of vehicles, or of several sets/units, the term formation is used. (Although the UK public and media often forgo formation, for simply train.) The word rake is also used for a group of coaches or wagons. In the United Kingdom Section 83(1) of the Railways Act 1993 defines “train” as follows:

a) Two or more items of rolling stock coupled together, at least one of which is a locomotive; or

b) A locomotive not coupled to any other rolling stock.

United States:

In the United States, the term consist is used to describe the group of rail vehicles which make up a train. When referring to motive power, consist refers to the group of locomotives powering the train. Similarly, the term trainset refers to a group of rolling stock that is permanently or semi-permanently coupled together to form a unified set of equipment (the term is most often applied to passenger train configurations).

The Atchison, Topeka and Santa Fe Railway’s 1948 operating rules define a train as: “An engine or more than one engine coupled, with or without cars, displaying markers.”

_

A train is a form of rail transport consisting of a series of connected vehicles that usually runs along a rail track to transport cargo or passengers. Motive power is provided by a separate locomotive or individual motors in self-propelled multiple units. Although historically steam propulsion dominated, the most common modern forms are diesel and electric locomotives, the latter supplied by overhead wires or additional rails. Other energy sources include horses, engine or water-driven rope or wire winch, gravity, pneumatics, batteries, and gas turbines. Train tracks usually consist of two parallel running rails, sometimes supplemented by additional rails such as electric conducting rails and rack rails, with a limited number of monorails and maglev guideways in the mix. The word ‘train’ comes from the Old French trahiner, from the Latin trahere ‘pull, draw’.

_

There are various types of trains that are designed for particular purposes. A train may consist of a combination of one or more locomotives and attached railroad cars, or a self-propelled multiple units e.g. Mainline Electric Multiple Unit or MEMU commuter rail system (or occasionally a single or articulated powered coach, called a railcar). The first trains were rope-hauled, gravity powered or pulled by horses. From the early 19th century almost all were powered by steam locomotives. From the 1910s onwards the steam locomotives began to be replaced by less labor-intensive and cleaner (but more complex and expensive) diesel locomotives and electric locomotives, while at about the same time self-propelled multiple unit vehicles of either power system became much more common in passenger service.

_

- Passenger Railroad Systems:

A passenger train is one which includes passenger-carrying vehicles which can often be very long and fast. One notable and growing long-distance train category is high-speed rail (HSR). In order to achieve much faster operation over 500 km/h (310 mph), innovative maglev technology has been researched for years. In most countries, such as the United Kingdom, the distinction between a tramway and a railway is precise and defined in law.

_

Amtrak is the only nationwide passenger railroad system in the United States. Amtrak operates on tracks owned by host railroads. In fact, 70 percent of Amtrak routes are owned by Class I freight companies. It serves more than 500 destinations in 46 states. In 2007, Amtrak carried 25.8 million passengers (average of 70,000 passengers on 300 trains daily). Amtrak receives federal, state and local support in return for offering passenger and commuter services. Despite the government support and increased ridership, Amtrak hasn’t turned a profit. In 2007, Amtrak’s expenses exceeded its revenues by about $1 billion. One potential reason for the shortfall is the fact that Amtrak faces steep competition from automobiles and airlines.

In the United States, passenger rail traffic hasn’t caught on for several reasons:

- The country lacks a passenger rail network that’s independent of the freight railroad system, so not all areas of the country have access to railroads.

- Until recently, the price of oil has still been relatively cheap, which makes automobiles and airlines more desirable modes of transportation for many people.

- Many trains are still relatively slow or make many stops. For example, a train trip from Raleigh, N.C. to Washington, D.C., can take five hours, which is the same amount of time that it takes to drive between these two cities.

However, as oil prices increase, Americans will seek alternative means for long-distance travel, and trains are a good candidate.

In contrast, European railway systems are devoted primarily to passenger traffic. Most European railways are government-owned. In 1959, the Eurail Group was created to handle the increased tourism load. The organization coordinates and markets passenger rail traffic among 30 European countries. The European network connects most European cities. Eurail’s high-speed trains have become competitive with airlines and are more efficient than automobiles. India, Russia, China, Korea, Japan and Australia also offer passenger rail service. Each country has an extensive rail network for passenger travel. Furthermore, the European train network is being linked to railways that travel to China, India and Southeast Asia. However, not all countries or continents have established international rail networks. Neither Africa nor Central or South America boast such networks. And while Mexico, Peru, Brazil, South Africa and Morocco have trains, those trains operate on tracks located solely within those countries.

_

- Freight Railroad Systems:

A freight train (also known as a goods train) uses freight cars (also known as wagons or trucks) to transport goods or materials (cargo). Freight and passengers may be carried in the same train in a mixed consist. Railroads are perhaps the cheapest way to haul freight overland. According to the Association of American Railroads (AAR), the U.S. freight train system leads the world in volume of traffic, amount of freight hauled, revenues, affordability, miles of track and other measures. Freight railroads carry lots of stuff, but the most common item is coal for electrical power plants. Chemicals, farm products, nonmetallic minerals, mixed shipments and other commodities make up the major categories. The success of the U.S. freight railroad system has shown that moving goods by rail can be economical, efficient and profitable. Trains are an essential part of a country’s infrastructure.

_

- Rail cars and machinery used for maintenance and repair of tracks, etc., are termed maintenance of way equipment; these may be assembled into maintenance of way trains. Similarly, dedicated trains may be used to provide support services to stations along a train line, such as garbage or revenue collection.

_

- Light rail:

The term light rail is sometimes used for a modern tram system, but it may also mean an intermediate form between a tram and a train, similar to a heavy rail rapid transit system except that it may have level crossings. Light rail is a city-based rail system based on tram design standards that operates mostly in private rights-of-way separated from other traffic but sometimes, if necessary, mixed with other traffic in city streets. Light rail vehicles (LRV) generally have a top speed of around 55 mph (89 km/h) though mostly operating at much lower speeds, more akin to road vehicles. Light rail vehicles usually run on trackage that weighs less per foot (due to a smaller track profile) than the tracks used for main-line freight trains; thus they are “light rail” due to the smaller rails usually used.

_

Locomotive:

Train engine is the technical name for a locomotive attached to the front of a railway train to haul that train. Alternatively, where facilities exist for push-pull operation, the train engine might be attached to the rear of the train. Traditionally, locomotives pulled trains from the front. However, push-pull operation has become common, where the train may have a locomotive (or locomotives) at the front, at the rear, or at each end. A locomotive or engine is a rail transport vehicle that provides the motive power for a train. A locomotive has no payload capacity of its own, and its sole purpose is to move the train along the tracks. In contrast, some trains have self-propelled payload-carrying vehicles. These are not normally considered locomotives, and may be referred to as multiple units, motor coaches or railcars. The use of these self-propelled vehicles is increasingly common for passenger trains, but rare for freight. Vehicles which provide motive power to haul an unpowered train, but are not generally considered locomotives because they have payload space or are rarely detached from their trains, are known as power cars.

_

As a general rule of thumb, locomotives will generally weigh in at 30-35 tons per axle, with the average 4-axle locomotive around 125 tons and a 6-axle locomotive around 200 tons. The current ‘average’ empty weight of boxcar (goods wagon) varies from 25-30 tons. The payload capacity of that boxcar can vary from 50-70 tons. The average empty Amtrak passenger car weighs about 65 tons.

_

There are three types of locomotive: electric, diesel and steam. The job of the locomotive is to change the chemical energy from the fuel (wood, coal, diesel fuel) into the kinetic energy of motion. The first locomotives did this with a steam engine that lasted for about a century, but was eventually replaced by the diesel locomotive, a mighty mechanical wonder that may consist of a giant engine along with electric alternators or generators to provide electrical power to the train. Many trains intersperse multiple locomotives throughout their lineup to increase and distribute the power. Besides steam- and diesel-powered locomotives, many trains operate solely on electrical power. They get the electricity from a third rail, or electrical line, along the track. Transformers transfer the voltage from the lines, and the electrical current drives the motors (AC or DC) on the wheels. Electrical locomotives are used on subways and many commuter rail systems.

_

Bogie:

A bogie is a wheeled wagon or trolley. In mechanics terms, a bogie is a chassis or framework carrying wheels, attached to a vehicle. It can be fixed in place, as on a cargo truck, mounted on a swivel, as on a railway carriage or locomotive, or sprung as in the suspension of a caterpillar tracked vehicle. Usually, two bogies are fitted to each carriage, wagon or locomotive, one at each end. An alternate configuration often is used in articulated vehicles, which places the bogies (often jacobs bogies) under the connection between the carriages or wagons. Most bogies have two axles, as this is the simplest design, but some cars designed for extremely heavy loads have been built with up to five axles per bogie. Heavy-duty cars may have more than two bogies using span bolsters to equalize the load and connect the bogies to the cars. Usually, the train floor is at a level above the bogies, but the floor of the car may be lower between bogies, such as for a double decker train to increase interior space while staying within height restrictions, or in easy-access, stepless-entry, low-floor trains.

_

All railroad cars have an undercarriage that contains wheels and a suspension system to buffer the ride. On each end of the undercarriage, couplers, which are like hooks, connect the cars.

What’s on top of the undercarriage depends upon the type of railroad car, and there are several.

- A boxcar is a basic box into which crates of goods can be piled up.

- An ore car has an open top and carries coal or other mineral ore such as bauxite.

- A tank car holds liquids, usually chemicals such as chlorine and ammonia.

- Flat cars can hold bulky irregular items on them, such as construction equipment or spools.

- Trailer cars can transport automobiles.

- Container cars are filled with boxed containers of various materials. Often, containers can be double-stacked on these cars.

- Passenger cars, of course, hold people. Some have glass-enclosed viewing areas on top, and some may even be sleeper cars for long trips.

_

Driver or engine driver or operator or engineer:

Driver only operation (DO or DOO) is operation of a train by the engineer or driver only. It is also known as one person train operation (OPTO). Operators control the train by using the throttle, reversing gear and brake. The throttle controls the speed of the locomotive. The reversing gear enables the locomotive to back up. The brake allows the locomotive to slow and stop. Regardless of the type, locomotives use air brakes and hand brakes to stop the engine. Air brakes use high-pressure air to drive the brake foot against the wheel. The friction between the brake pad and the wheels slows the wheels’ motions. The operator also throttles the engine back to slow the train, like when you take your foot off the gas pedal when stopping your car. A mechanical hand brake is also used in case the air brakes fail (usually when there’s insufficient air pressure to drive them).

_

Train operation modes:

Train operation modes may be classified as follow:

- Full Traction mode: In this mode, master controller is kept in full traction position.

- Driving in Allout mode: means full traction up to maximum service speed.

- Cruising mode: In this mode, train is operated with constant speed and develop tractive effort equal to train resistance; hence value of acceleration is zero.

- Coasting Mode: In this mode, no electric energy is supplied to traction motors and energy required to overcome train resistance is supplied from its kinetic energy, which result gradual reduction in train speed.

- Full service brake: In this mode, master controller is kept in full service brake position.

_

Service Brake & Emergency Brake:

Train brake system:’

To stop or slow, trains typically rely on some combination of three braking systems, including dynamic braking, which entails use of the locomotives’ electric motors to dissipate energy; air-braking system, that operates throughout the train; and independent brakes on board of the locomotives. Air brake system uses air pressure to charge air reservoirs (tanks) on each car. Full air pressure signals each car to release the brakes. A reduction or loss of air pressure signals each car to apply its brakes, using the compressed air in its reservoirs. Air operated brakes used hoses connecting all the wagons of a train, so the driver could apply or release the brakes with a single valve in the locomotive.

Modern air brake systems serve two functions:

- The service brake system, which applies and releases the brakes during normal operations, and

- The emergency brake system, which applies the brakes rapidly in the event of a brake pipe failure or an emergency application by the engine operator (generally referred to as the automatic brake). The emergency brake applies considerably more braking force than the full-service brake.

_

Railway signalling:

Railway signalling is a system used to direct railway traffic and keep trains clear of each other at all times. Trains move on fixed rails, making them uniquely susceptible to collision. This susceptibility is exacerbated by the enormous weight and inertia of a train, which make it difficult to quickly stop when encountering an obstacle. Most forms of train control involve movement authority being passed from those responsible for each section of a rail network (e.g., a signalman or stationmaster) to the train crew. The set of rules and the physical equipment used to accomplish this determine what is known as the method of working (UK), method of operation (US) or safeworking (Aus.). Not all these methods require the use of physical signals, and some systems are specific to single track railways.

_

Block signalling:

Trains cannot collide with each other if they are not permitted to occupy the same section of track at the same time, so railway lines are divided into sections known as blocks. In normal circumstances, only one train is permitted in each block at a time. This principle forms the basis of most railway safety systems. Most blocks are “fixed”, i.e. they include the section of track between two fixed points. On timetable, train order, and token-based systems, blocks usually start and end at selected stations. On signalling-based systems, blocks start and end at signals. The lengths of blocks are designed to allow trains to operate as frequently as necessary. A lightly used line might have blocks many kilometres long, but a busy commuter line might have blocks a few hundred metres long.

_

A train is not permitted to enter a block until a signal indicates that the train may proceed, a dispatcher or signalman instructs the driver accordingly, or the driver takes possession of the appropriate token. In most cases, a train cannot enter the block until not only the block itself is clear of trains, but there is also an empty section beyond the end of the block for at least the distance required to stop the train. In signalling-based systems with closely spaced signals, this overlap could be as far as the signal following the one at the end of the section, effectively enforcing a space between trains of two blocks.

_

When calculating the size of the blocks, and therefore the spacing between the signals, the following have to be taken into account:

- Line speed (the maximum permitted speed over the line-section)

- Train speed (the maximum speed of different types of traffic)

- Gradient (to compensate for longer or shorter braking distances)

- The braking characteristics of trains (different types of train, e.g., freight, High-Speed passenger, have different inertial figures)

- Sighting (how far ahead a driver can see a signal)

- Reaction time (of the driver)

Historically, some lines operated so that certain large or high speed trains were signalled under different rules and only given the right of way if two blocks in front of the train were clear.

_

Train detection

The most common way to determine whether a section of line is occupied is by use of a track circuit. The rails at either end of each section are electrically isolated from the next section, and an electrical current is fed to both running rails at one end. A relay at the other end is connected to both rails. When the section is unoccupied, the relay coil completes an electrical circuit, and is energized. However, when a train enters the section, it short-circuits the current in the rails, and the relay is de-energized. This method does not explicitly need to check that the entire train has left the section. If part of the train remains in the section, the track circuit detects that part. This type of circuit detects the absence of trains, both for setting the signal indication and for providing various interlocking functions—for example, preventing points from being moved while a train is approaching them. Electrical circuits also prove that points are locked in the appropriate position before the signal protecting that route can be cleared.

_

Fixed block system and moving block system:

One disadvantage of having fixed blocks is that the faster trains are allowed to run, the longer the stopping distance, and therefore the longer the blocks need to be, thus decreasing the line’s capacity. The fixed blocks must be sized for the worst case stopping distance, regardless of the actual speed of the trains. Under a moving block system, computers calculate a “safe zone” around each moving train that no other train is allowed to enter. The system depends on knowledge of the precise location and speed and direction of each train, which is determined by a combination of several sensors: active and passive markers along the track, and train-borne speedometers; (GPS systems cannot be relied upon because they do not work in tunnels). With a moving block setup, lineside signals are unnecessary, and instructions are passed directly to the trains. This has the advantage of increasing track capacity by allowing trains to run closer together while maintaining the required safety margins.

________

________

List of countries by rail transport network size based on International Union of Railways data:

| Rank | Country | Railway length (km) |

Electrified length (km) |

Area (km2) per km track | Population per km track | Nationalized or Private |

| 1 | United States | 250,000 | <1,600 | 43.71 | 1,373 | Private |

| 2 | China | 124,000 | 80,000 | 77.4 | 11,048 | Nationalized |

| 3 | India | 115,000 | 23,883 | 48.34 | 17,796 | Nationalized |

| 4 | Russia | 86,000 | 50,000 | 198.82 | 1,669 | Nationalized |

| 5 | Canada | 46,552 | 129 | 214.48 | 716 | Private |

| 6 | Germany | 43,468 | 19,973 | 8.22 | 1,881 | Both |

| 7 | Australia | 38,445 | 2,715 | 199.94 | 572 | Both |

| 8 | Brazil | 37,743 | 6,988 | 299.6 | 6,986 | Private |

| 9 | Argentina | 36,966 | 136 | 77.45 | 1,117 | Nationalized |

| 10 | South Africa | 31,000 | 24,800 | 39.39 | 1,742 | Nationalized |

| 11 | France | 29,640 | 15,140 | 21.53 | 2,201 | Nationalized |

__

The United States has the world’s longest railway network, followed by China and India. The US rail network, with an operating route length over 250,000km, is the biggest in the world. Freight lines constitute about 80% of the country’s total rail network, while the total passenger network spans about 35,000km. The US freight rail network consists of 538 railroads (seven Class I railroads, 21 regional railroads, and 510 local railroads) operated by private organisations. Union Pacific Railroad and BNSF Railway are among the largest freight railroad networks in the world. The national passenger rail network Amtrak comprises of more than 30 train routes connecting 500 destinations across 46 American states. Trains carry 40 percent of America’s freight as well as 650 million passengers a year, and in general, their safety record is good and getting better. A plan is in place to build a 27,000km national high speed rail system in four phases by 2030. Construction of the California high-speed rail, the country’s first high-speed rail project, was well underway by the beginning of 2014. Three more high-speed projects including the Midwest high-speed rail line connecting Chicago with Indianapolis or St. Louis, Texas high-speed rail, and the Northeast High-Speed Corridor are under development.

China’s rail network, with a route length of over 124,000km, ranks as the second biggest rail network in the world. The extensive network, operated by state-owned China Railway Corporation, carried 2.08 billion passengers (the second highest after Indian Railways) and 3.22 billion tonnes of freight (the second highest after the US railway network) in 2013. The rapid expansion of China’s high-speed rail network in recent years makes it by far the largest in the world. The 2,298km Beijing – Guangzhou high speed line is the world’s longest high-speed railway line. The total length of China’s high-speed rail network is projected to reach 50,000km by 2020.

The Indian nationwide rail network, the third longest in the world, is owned and operated by state-owned Indian Railways and includes an operating route length of more than 115,000km. The network carried about 8.4 billion passengers (the highest in the world) and 1.01 million tonnes of freight (fourth highest in the world) in 2013. The Indian railway network is divided into 17 zones and operates more than 19,000 trains per day, including 12,000 passenger trains and 7,000 freight trains. Six high-speed corridors have also been identified for implementation in the country. The 534km Mumbai-Ahmedabad high-speed link is being advanced as a pilot project.

_

Countries without railway currently:

- Andorra

- Bhutan

- Cyprus

- Timor-Leste

- Guinea-Bissau

- Iceland

- Kuwait

- Libya

- Macau

- Malta

- Marshall Islands

- Mauritius

- Micronesia

- Niger

- Oman

- Papua New Guinea

- Qatar

- Rwanda

- San Marino

- Solomon Islands

- Somalia

- Suriname

- Tonga

- Trinidad and Tobago

- Tuvalu

- Vanuatu

- Yemen

______

______

Structure and function of railways:

__

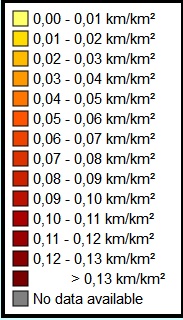

Railway track:

Railroad tracks guide the train, acting as the low-friction surface on which the train runs and often transferring the weight of the train to the ground below. Train tracks help steer the train in the direction it needs to go. Running on tracks allows a train to go faster than other types of ground transportation, like cars.

_

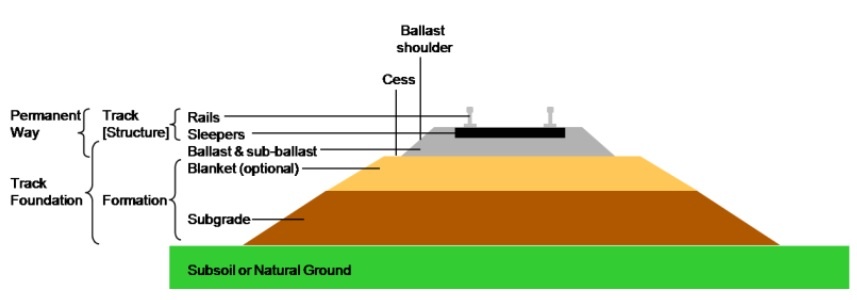

Rails are the members of the track laid in two parallel lines to provide an unchanging, continuous, and level surface for the movement of trains. To be able to withstand high amount of stresses these are made of high carbon steel. A railway track or railway line is a set of two parallel rows of long pieces of steel i.e. rails. They are used by trains to transport people and things from one place to another. Often, there is more than one set of tracks on the railway line. For example, trains go east on one track and west on the other one. The rails are supported by cross pieces set at regular intervals (called sleepers or ties), which spread the high pressure load imposed by the train wheels into the ground. They also maintain the rails at a fixed distance apart (called the gauge). Ties are usually made from either wood or concrete. The rails are usually bolted to the ties. The ties are set into the loose gravel or ballast which is a name for very small pieces of broken up rock that are packed together and keep the railway tracks in place. Ballast help transfer the load to the underlying foundation. The ties “float” on the ballast and the weight of the track keeps them stabilized. Tracks are often made better by ballast tampers.

_

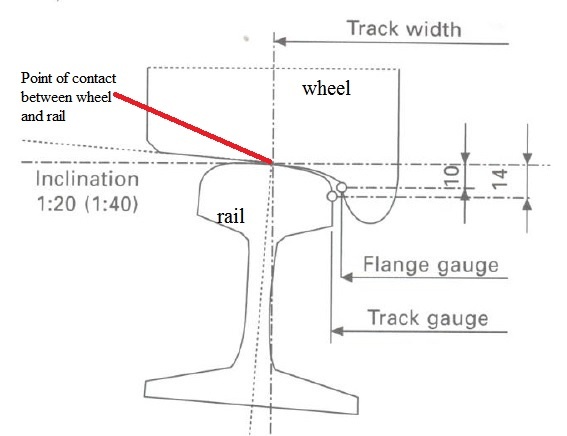

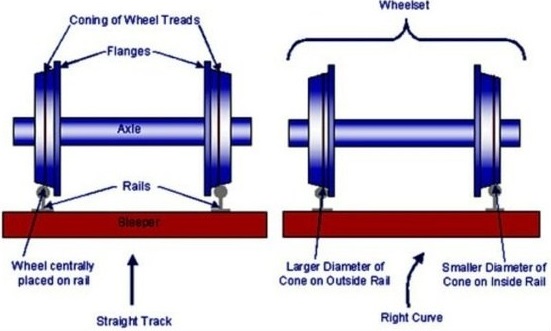

When rail workers are laying train tracks, they often use a flat-bottom steel rail that resembles the steel I-beam girders of construction. The rail has a wide base or foot, a narrow web and a head (wider than the web, but not as wide as the foot). The weights of the rails vary from 80 to 160 pounds (36 to 73 kilograms) per yard depending upon the type of train operating on the tracks and the country. Segments of rail track may connect to one another by bolted plates called fishplates, but most modern rail segments are welded together to provide a smooth ride. The rails are inclined slightly towards each other, typically on a slope of 1 in 20, and the rims of the train wheels are angled in the same way (“coning”). This helps guide the vehicles of the train along the track. Each wheel also has a flange, which sticks out from one edge all the way around. This makes sure the train does not “derail” (come off the track) and helps guide the train on sharp curves. Tracks where electric trains or electric trams run are equipped with an electrification system such as an overhead electrical power line or an additional electrified rail i.e. third rail.

_

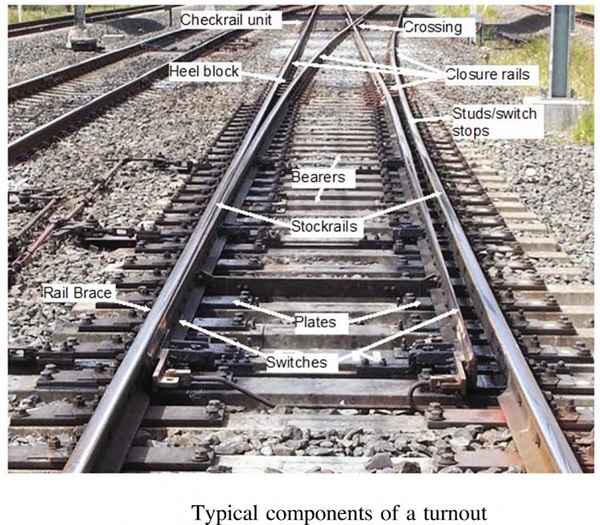

Steel tracks can be straight or curved to steer the train since steel is easily bent into shape. Depending upon the topography, some curves may be slightly angled or banked to help the train stay on the track as it negotiates the curve. At various points along the track, rails may have switches, which can move a train from one track to another. Switches and accompanying track are important for controlling traffic. For example, when two trains are operating on the same track, a switch can allow one train to pull off to a holding track while the other one passes. A switch also can change a train’s direction like moving it from a north-south track to an east-west one. Many railroad stations have switching yards where trains are assembled and moved onto various tracks. Finally, signals along the tracks keep the train operators informed of traffic conditions ahead. Signals control train traffic much like traffic lights control automobile traffic on roads. Besides signals, many locomotives have radios and computer terminals that monitor traffic conditions using information supplied by signalling centers, which are similar to air traffic control stations.

_____

_____

Rails:

Early rails were made of wood, cast iron or wrought iron. All modern rails are hot rolled steel with a cross section (profile) approximate to an I-beam, but asymmetric about a horizontal axis. The head is profiled to resist wear and to give a good ride, and the foot profiled to suit the fixing system. Unlike some other uses of iron and steel, railway rails are subject to very high stresses and are made of very high quality steel. It took many decades to improve the quality of the materials, including the change from iron to steel. Minor flaws in the steel that may pose no problems in other applications can lead to broken rails and dangerous derailments when used on railway tracks. By and large, the heavier the rails and the rest of the trackwork, the heavier and faster the trains these tracks can carry. Rails represent a substantial fraction of the cost of a railway line. Only a small number of rail sizes are made by steelworks at one time, so a railway must choose the nearest suitable size. Worn, heavy rail from a mainline is often reclaimed and downgraded for re-use on a branchline, siding or yard.

_

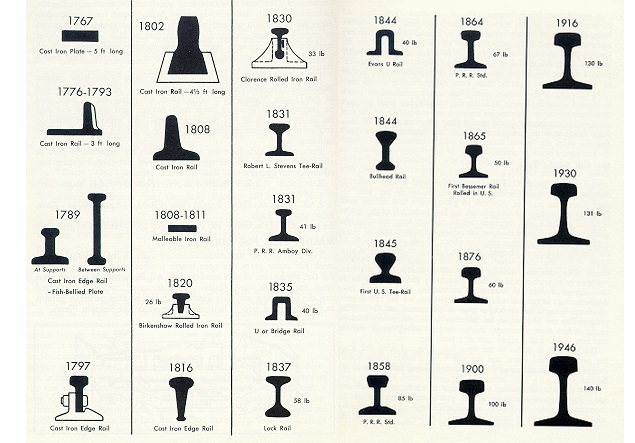

Rail development:

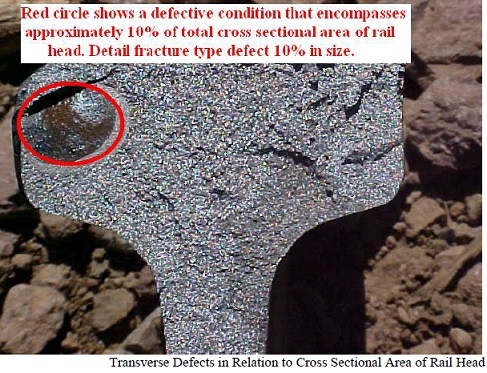

The rails have evolved from cast iron plates to specially alloyed steels, which are rolled to a standard shape and specially heat-treated to obtain the desired properties. The figures above show the progression of rail development. Present day steel rails are vastly superior to their predecessors in both strength and wear qualities, however defects still develop. The heavy loads and high speed of today’s trains can cause rails to fail in service unless regular inspections are performed.

_

The earliest aspects of railroad infrastructure are, of course, the track and roadbed. Railroad track, as with railroading itself, has its roots in England where for years coal mines had been using horses or mules to pull carts that used flanged wheels to operate on wooden or strap-iron rails (which was essentially a wooden rail with a piece of flat iron attached to the top). This type of track remained in use as late as the 1840s (by this point strap-rail was the norm) until solid iron “T”-rail was developed by Robert Stevens, president of the Camden & Amboy Railroad, it was a revolutionary design still used to this day. The unstable and dangerous strap-rail (which was simply thin pieces of iron attached to wooden planks) that caused the deadly phenomenon of “snake heads” (which was an iron strap that came loose and was peeled upward by a passing car wheel and it acted as a can opener when the next train passed over the broken rail literally ripping the train apart and almost always killing passengers and sometimes crewmen) was replaced by solid iron ‘T’ rails. Today ‘T’ rail is replaced with ‘I’ rail.

_

Rail profile:

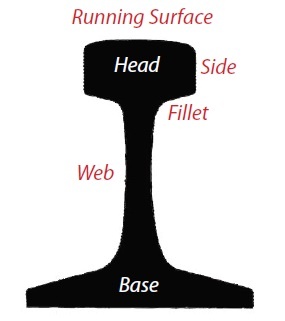

The rail profile is the cross sectional shape of a railway rail, perpendicular to its length.

_

Why do a rails have a particular shape like I?

These are shaped so for following purposes:

- The top portion or the HEAD of the rail is thicker to take up the impact of the fast moving wheels, and carry the load of trains preventing abrasion of the tracks.

- The WEB of the rail is to uplift the train from the ground level; and to provide clear cover (distance) between wheel base plus flanges and the sleeper/ ballast layer.

- The FOOT provides two-fold purpose. Easy clamping i.e. fixing to the sleeper beneath it because of wider area as well as greater surface area helps in load transfer to the sleeper more efficiently which further transfers the load to ballast and later sub-base.

Upper half should be wide enough to support the wheel and lower half should be wide & thick enough for clamping. Taking out extra materials saves significant amount of iron without compromising over strength thus giving it ‘I’ shape. It has to be symmetrical so that it can be used on the left and the right track.

The usual, Flat Footed rails used for Broad Gauge lines is shown below with its components. This is typical shape of the cross-section of a track laid with Flat-footed Rails. The Bull headed rails resemble the ‘I’ shape more correctly.

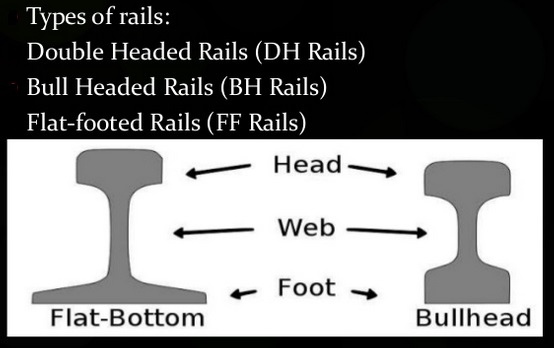

Types of rails:

- Double Headed Rails (DH Rails)

- Bull Headed Rails (BH Rails)

- Flat-footed Rails (FF Rails)

_

Rail weights and sizes:

Two commonly used rail profiles: a heavily worn 50-kg/m profile and a new 60-kg/m profile. The weight of a rail per length is an important factor in determining rails strength and hence axleloads and speeds. Weights are measured in pounds per yard or kilograms per metre; the pounds-per-yard figure is almost exactly double the kilograms-per-metre figure. Rails in Canada, the United Kingdom and United States are described using imperial units. In Australia, metric units are used as in mainland Europe. Commonly, in rail terminology Pound is a contraction of the expression pounds per yard and hence a 132–pound rail means a rail of 132 pounds per yard.

Rails are made in a large number of different sizes. Some common European rail sizes include:

- 40 kg/m (81 lb/yd)

- 50 kg/m (101 lb/yd)

- 54 kg/m (109 lb/yd)

- 56 kg/m (113 lb/yd)

- 60 kg/m (121 lb/yd)

In the countries of former USSR 65 kg/m (131 lb/yd) rails and 75 kg/m (150 lb/yd) rails (not thermally hardened) are common. Thermally hardened 75 kg/m (150 lb/yd) rails also have been used on heavy-duty railroads like Baikal–Amur Mainline, but have proven themselves deficient in operation and were mainly rejected in favor of 65 kg/m (131 lb/yd) rails.

_

Rail gauge:

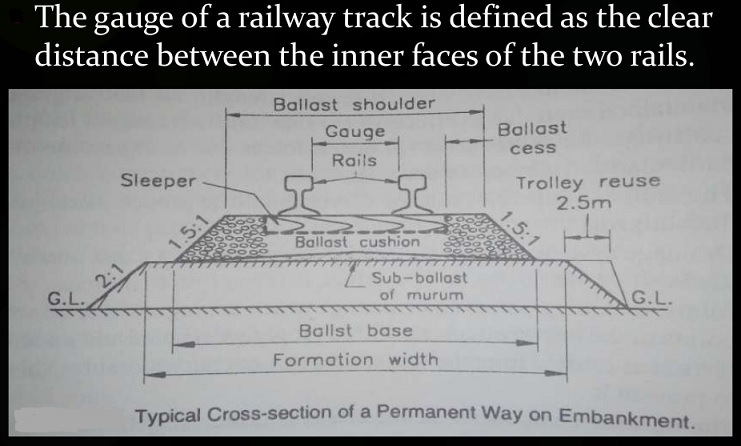

The gauge of a railway track is defined as the clear distance between the inner faces of the two rails.

Dimension of gauges

- Broad Gauge (BG) 1676mm (5’6”)

- Standard Gauge (SG) 1435mm

- Meter Gauge (MG) 1000mm

- Narrow Gauge (NG) 762mm (2’6”)

- Light Gauge 610mm

Broad gauge is where the rails are spaced more widely apart than 1,435 mm (4 ft 8 1⁄2 in) which is called standard gauge. Many early railroads were broad gauge, for example the Great Western Railway in the UK which adopted 7 ft (2,134 mm) gauge until it was converted to standard gauge in the 1860s – 1890s. Russia still has over 80,000 km (50,000 mi) of broad gauge [1,520 mm (4 ft 11 27⁄32 in)] railroads. Broad gauge is also normal in Spain and Portugal [1,668 mm (5 ft 5 21⁄32 in)], in India and Sri Lanka [1,676 mm (5 ft 6 in)], as well as Ireland and used in some parts of Australia [1,600 mm (5 ft 3 in)].

_

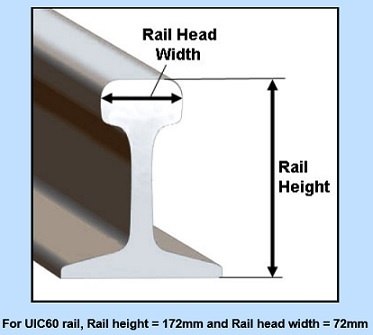

Height and width of rails:

_

Length of Rails:

Rails should be made as long as possible since joints between rail lengths are a source of weakness. As manufacturing processes have improved, rail lengths have increased. Long rails are flexible, and there is no problem going around curves.

On Indian Railways the standard lengths are the following: Length = 12.80 m. (42 ft.) for BG and Length = 11.9 m. (39 ft.) for MG

Length = 39 feet (11.9 m) in United States and 60 feet (18.3 m) in London and North Western Railway (UK).

_

Weight and section of rail are governed by many factors:

- Gauge of track

- Max. Permissible speed

- Type and spacing of sleepers

- Depth of ballast cushion

- Heaviest moving load likely to cross over the rail

- Spacing of sleepers

_

Maximum axle load that can be carried by a rail depends on its weight:

In India the capacity will be calculated as follows:

Max axle load = 560 X sectional weight of rail in kg/m

For 52 kg rail, max. axle load = 560 X 52 = 29.12 tonnes

_

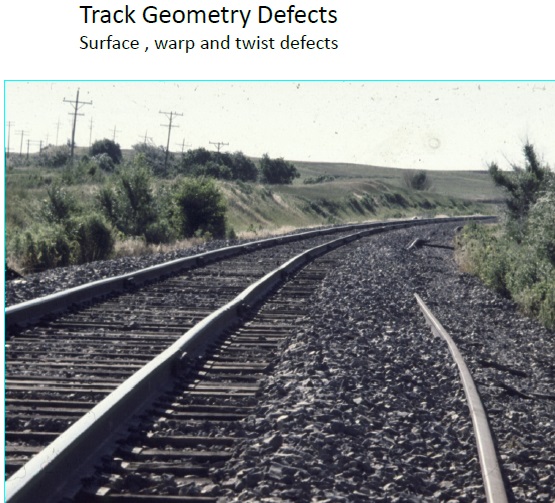

Track Geometry Parameters:

- Surface (left, right)

- Cross-level (super-elevation)

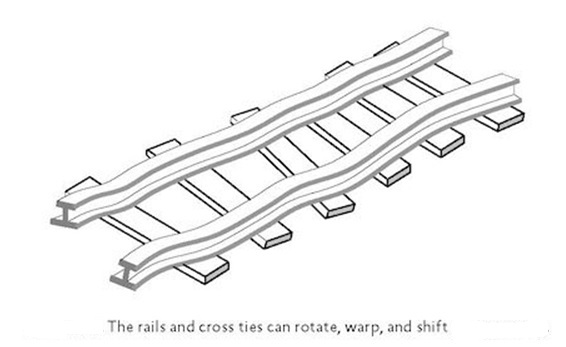

- Twist (warp)

- Alignment (left, right)

- Curvature

- Gauge

______

Functions of Rails:

Rails are similar to steel girders. These are provided to perform the following functions in a track.

- Rails provide a continuous and level surface for the movement of trains.

- Rails provide a pathway which is smooth and has very little friction.

- Rails serve as a lateral guide for the wheels.

- Rails bear the stresses developed due to vertical loads transmitted to them through axles and wheels of rolling stock as well as due to braking and thermal forces.

- Rails carry out the function of transmitting the load to a large area of the formation through sleepers and the ballast.

_______

Requirements of Ideal rail:

- The section of the rail should be such that the load of each wheel is transferred to the sleepers without exceeding the permissible stresses

- The section of the rail should be able to withstand the lateral forces caused due to fast moving trains.

- The bottom of head and top of foot should be given such shapes that fishplates can be easily fitted.

- The centre of gravity of the rail section should preferably coincide the centre of the height of the rail so that maximum tensile and compressive stresses are nearly equal.

- The web of the rail section should be such that it can safely bear the vertical load without buckling.

- The head of the rail should be sufficiently thick for adequate margin of vertical wear.

- The foot of rail should provide sufficient bearing area on the underlying sleepers so that the compressive stresses on the timber sleeper remain within permissible limits.

- The section of the rails should be such that the ends of two adjacent rails can be efficiently jointed with a pair of fish plates.

- The surfaces for rail table and gauge face should be sufficiently hard to resist the wear.

- The contact area between the rail and wheel flange should be as large as possible to reduce the contact stresses.

- The specimen of rail should be able to withstand the blow of a falling weight in the test specified by the specifications

- The composition of the steel should conform to the specifications adopted for its manufacture by Open Hearth of Duplex Process

- The overall height of the rail should be adequate to provide sufficient stiffness and strength as a simply supported beam.

- The foot of the rail should be wide enough so that the rail is stable against overturning.

- There should be balanced distribution of metal in head, web and foot.

_____

Joining rails:

Rails are produced in fixed lengths and need to be joined end-to-end to make a continuous surface on which trains may run. Jointed track is made using lengths of rail, usually around 20 m (66 ft) long (in the UK) and 39 or 78 ft (12 or 24 m) long (in North America), bolted together using perforated steel plates known as fishplates (UK) or joint bars (North America). Fishplates are usually 600 mm (2 ft) long, used in pairs on either side of the rail ends and bolted together (usually four, but sometimes six bolts per joint). The bolts may be oppositely-oriented so that in the event of a derailment and a wheel flange striking the joint, only some of the bolts will be sheared, reducing the likelihood of the rails misaligning with each other and exacerbating the seriousness of the derailment. This technique is not applied universally, European practice being to have all the bolt heads on the same side of the rail. Small gaps which function as expansion joints are deliberately left between the rail ends to allow for expansion of the rails in hot weather. If these gaps are not left then the tracks might have enormous stress in them while expanding due to heat which can cause buckling of rails and derailment. European practice was to have the rail joints on both rails adjacent to each other, while North American practice is to stagger them. Because of the small gaps left between the rails, when trains pass over jointed tracks they make a “clickety-clack” sound. Unless it is well-maintained, jointed track does not have the ride quality of welded rail and is less desirable for high speed trains. However, jointed track is still used in many countries on lower speed lines and sidings, and is used extensively in poorer countries due to the lower construction cost and the simpler equipment required for its installation and maintenance. A major problem of jointed track is cracking around the bolt holes, which can lead to breaking of the rail head (the running surface). This was the cause of the Hither Green rail crash which caused British Railways to begin converting much of its track to continuous welded rail. So for more modern usage, particularly where higher speeds are required, the lengths of rail are welded together to form continuous welded rail (CWR).

_

Continuous welded rail (CWR):

Throughout most of the 19th century iron was the primary choice for railroad track and every other structure being built. However, in the 1890s the much stronger and durable steel was introduced. Steel was not only much stronger than iron but because it had a longer lifespan railroads were willing to pay a little more for it as in the end it meant an improved bottom line. It was not until the 1950s that railroad track would see another major change. That decade saw the first use of continuous welded rail (CWR), also known as ribbon rail, which is laid in lengths of 1,500 feet or so (roughly a 1/4-mile), rather than 39-foot track bolted together. Aside from saving railroads millions in maintenance costs and derailments, CWR does not buckle, because it resists thermal expansion and contraction. Once the benefits of CWR were realized the industry quickly began replacing its most heavily trafficked main lines with the new type of railroad track and by the 1970s most of these routes employed it. Even better for railroads was the fact that CWR did not necessarily have to be purchased new. If a rail line already contained the desired track weight (such as 100, 110, or 120-pound rail) it could simply be welded into strings and relaid costing only the maintenance time required.

_

The advantages to be gained from the use of CWR made its adoption almost inevitable once its practicability was established. Apart from the more comfortable ride for passengers these advantages included economic ones, such as an extension of rail life by between 30 per cent and 40 per cent, savings in the cost of track maintenance, extended sleeper life, and reduction in fuel costs and wear and tear on rolling stock, as well as the important gain in safety resulting from the elimination of rail joints. The latter have always been the weakest point in conventional jointed track and by far the greatest number of rail breaks, and those potentially the most dangerous, have been associated with the fishbolt holes at rail ends. The one drawback to CWR is its tendency to kink, or turn into spaghetti, during the high heat of summer. Known as sun kinks this phenomenon can result in either slow orders or the movements to be suspended entirely until the night or late evening when cooler temperatures allow the track to settle back into place. However, warm temperatures are needed when installing CWR as doing so in cold weather when the steel tends to contract can result in buckling and warping when warmer weather prevails. CWR has become a science into itself as railroads must make sure they install the rail correctly and in warm enough temperatures to keep kinking from occurring.

_______

Railroad tie/sleeper:

_

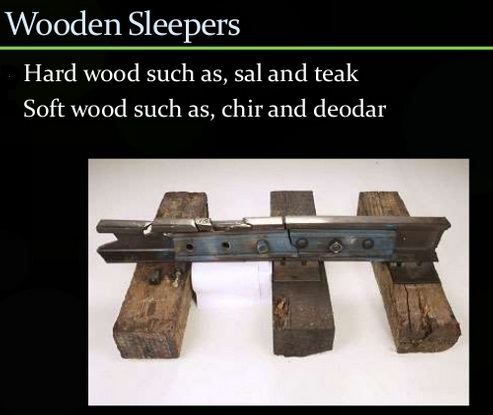

A railroad tie/railway tie/crosstie (North America) or railway sleeper (British Isles, Australasia, and Africa) is a rectangular support for the rails in railroad tracks. Generally laid perpendicular to the rails, transverse ties are laid to support the rails. They transmit wheel load from the rails to the ballast and subgrade, hold the rails upright and keep them spaced to the correct gauge. Railroad ties are traditionally made of wood, but pre-stressed concrete is now also widely used, especially in Europe and Asia. Steel ties are common on secondary lines in the UK; plastic composite ties are also employed, although far less than wood or concrete. As of January 2008, the approximate market share in North America for traditional wood ties was 91.5%, the remainder being concrete, steel, azobé (red ironwood) and plastic composite. Approximately 3,520 wooden crossties are used per mile of mainline railroad track in the US (distance between ties is nominally 18″ including one tie and the crib), 2,640 per mile (30 per 60 ft rail) on main lines in the UK. Rails in the US may be fastened to the tie by a railroad spike; iron/steel baseplates screwed to the tie and secured to the rail by a proprietary fastening system such as a Vossloh or Pandrol are commonly used in Europe.

_

Classification of sleepers/ties:

(i) Wooden sleeper

(ii) Metal sleeper, Cast iron sleeper, Steel sleeper

(iii) Concrete sleeper, Reinforced concrete Sleeper (R.C.C), Prestressed Concrete Sleeper

_

Railroad ties, also known as crossties or sleepers are the primary lateral support for the rails themselves, anchoring the track and giving it a solid, sound base upon which trains can pass over. Throughout the years crosstie technology has improved to the point that today, the common hardwood tie which has been properly treated with creosote can last at least 30-40 years before needing replaced. While the basic design and function of the tie has not changed much in more than a century, today’s technologies have allowed other materials to be utilized notably concrete and even plastics/composites that generally enhance its livelihood. In any event, while railroads have employed these new ties in some instances, especially concrete on heavily used main lines, wood remains the preferred choice due to its cost and generally-good life expectancy.

_

Today ties have a uniform size and thickness, usually at least 8-10 inches thick and about 8-10 feet in length, depending on what they are being used for (i.e., for switch outs or along a main line). There are also important components that hold railroad ties firmly to the rails. The most common of these in the simple spike, which is a basic anchor that is driven into the tie. However, there is also the tie plate, in which the spikes are driven into. This component not only provides a place to drive the spikes but also as a means of housing the rail and helping to distribute the weight over a broader area of the tie itself. Finally, there is the rail anchor. This component simply keeps the rails from shifting north and south as the train passes over. With the ballast the entire track infrastructure is complete providing for a strong, yet flexible operating surface. Today railroad ties are mass produced and are still most often of hardwood although with concrete’s added benefit of allowing for faster and heavier trains it is also becoming a top choice, particularly overseas and in Europe where passenger trains dominate. The one drawback to concrete is that because of its rigid qualities it does not have the same flexibility as wood, or even composite ties. However, its inherent strengths and longevity, even over wood, more than make up for its primary weakness as in the future you will almost surely see more and more main lines employing concrete ties.

______

Ballast:

Ballast (usually crushed stone), as it is known, is another important part of railroad infrastructure. Although it may just look like plain ole gravel this stone plays a vital role in acting as a support base for the railroad ties and rails as well as allowing for proper drainage of water away from the rails (which is why the stone is always sloped downward and away from track). You may be wondering how such a term came to define the stone which supports the railroad track structure. Interestingly, it has its roots dating back to early times when stone was used as ballasting for sailing ships. In today’s railroad industry the use of ballast, its application, and purpose has changed little since it was first employed and will likely always remain an important component as a part of the track structure. According to Brian Solomon’s book Railway Maintenance, The Men and Machines That Keep the Railroads Running, today the typical layout for a well-ballasted railroad track system is stone lined to the top of the railroad ties protruding roughly 14 inches to either side, tapering away on a “3-to-1” slope to an eventual distance of 9 feet, 10 inches from the center-of-track with the stone being about one-foot deep below the bottom of the ties.

_

These stones (called track ballast) serve four primary purposes:

- Load-bearing (it distributes and bears the weight of the railroad ties)

- Facilitation of water drainage away from the ties

- Keeps out vegetation that could interfere with the structure of the track

- Helps keep the ties in place

_

Ballast must regularly be cleaned or added as when dirt and grime builds up within the rock it reduces its ability to properly drain water. Ballast also acts as a support base for the railroad track structure giving it strength and rigidity but also allowing for flexibility when trains pass over. Limestone or quartz is often most used as ballasting because it is a hard stone that will lock together providing for extra strength. According to Brian Solomon’s book Railway Maintenance, The Men and Machines That Keep the Railroads Running, today’s trains can exert a force of 100 psi when passing over track and the stone used for ballasting must be able to withstand this constant abuse.

_

Optimum ballast gradation:

The ballast that is seen under the railway tracks in India are mostly prepared by crushing locally available rocks to generate specific-sized stones. In India, stones measuring 20 mm to 65 mm are permitted to be used as ballast. These sizes are slightly bigger than in many other countries, where even 9 mm ballast is used. The ballast has to fulfil two key objectives. They must have high shear strength to provide maximum stability and minimum track deformation. And, they must have high permeability to allow adequate drainage of water from the tracks in the rainy season. The size of ballast is also referred to as ballast gradation. Now, ballast of larger sizes does not allow for very tight packing; the void is large. This is good for the drainage function, but not ideal for providing maximum stability to the tracks. Because of the loose packing and presence of large voids, when load is applied on the ballast, for example, by a running train, it tries to rearrange itself. In the process, many of the stones break, parts of them getting converted into small granules. Besides these granules, there are also several foreign materials that get mixed into the ballast due to various processes. The trains, for example, carry coal or iron ore. Some of these drop from the wagons and get mixed with the ballast. Dust and mud, and a variety of other materials such as plastics and soil, too, settle in. This is called ballast fouling. Initially, this fouling leads to filling up the voids and helps in packing the ballast tightly. But with time, it starts to create problems. It facilitates the movement of the ballast and makes it easier for the sleepers to shift. This in turn can change the delicate alignment of the rails in the track, which can lead to a derailment. To deal with a problem like this, Indian Railways has to periodically carry out what is called deep-screening of the tracks. In this process, the tracks are lifted and the fouling is cleaned before replacing the tracks. This exercise, as of now, is randomly carried out. Prof Anbazhagan P and his team at the department of civil engineering at the Indian Institute of Science, Bangalore, have now tried to develop a method through which it would be possible to identify the tracks that need immediate deep-screening by studying the nature and extent of ballast fouling. The team has defined an “optimum” fouling point and “critical” fouling point to check state of fouling in the track. If the ballast has reached “optimum” fouling point, deep-screening is recommended immediately. If “critical” fouling point is reached, a track must not be used until it is deep-screened. Anbazhagan says his current research is to focus to define the “optimum” ballast gradation that would be the best suited for performing both the functions of allowing drainage and providing stability to the tracks. Many countries have already defined this “optimum” gradation for their own railway lines. He says these studies can be useful for the existing railway system and future high speed rails.

_

One often forgotten aspect of the ballasting system is what is known as sub-ballast or sub-grade. This layer of crushed stone or even pavement, as some railroads today now use acts as a moister barrier and added support system for the railroad track structure above (including the rails, ties, and ballast). It is always the first component of the track structure to be laid down and is a very important, unseen component. If the railroad track did not have a sub-ballasting system, or very poor one at best, the rails and railroad ties would eventually become water-logged and fail (causing a derailment, or worse, a washout).

_

The figure below shows profile of rail-track-ballast system:

_

Slab track (or ballastless track) would be preferable over ballast any day. It is basically track fixed directly to reinforced concrete slabs and has the advantage of increased stability and lower maintenance costs. It is however expensive, so sleepers and ballast are used instead. In some countries, slab track is used extensively on high speed, high frequency lines, such as Japan or around some areas where the track must be stable such as in tunnels or around stations. This is of course dependant on the amount of investment in rail infrastructure.

______

In the United States, the Federal Railroad Administration has developed a system of classification for track quality. The class of a section of track determines the maximum possible running speed limits and the ability to run passenger trains. The quality of railroad track is commonly divided into nine principal classes by FRA on the basis of track structure, track geometry, and inspection frequency and method. The higher the track class, the more stringent are the track safety standards and thus a higher maximum train speed is allowed.

| Track type | Freight train | Passenger train |

| Excepted | <10 mph (16 km/h) | not allowed |

| Class 1 | 10 mph (16 km/h) | 15 mph (24 km/h) |

| Class 2 | 25 mph (40 km/h) | 30 mph (48 km/h) |

| Class 3 | 40 mph (64 km/h) | 60 mph (97 km/h) |

| Class 4 | 60 mph (97 km/h) | 80 mph (129 km/h) |

| Class 5 | 80 mph (129 km/h) | 90 mph (145 km/h) |

| Class 6 | 110 mph (177 km/h) | |

| Class 7 | 125 mph (201 km/h) | |

| Class 8 | 160 mph (257 km/h) | |

| Class 9 | 220 mph (354 km/h). | |

_______

Note:

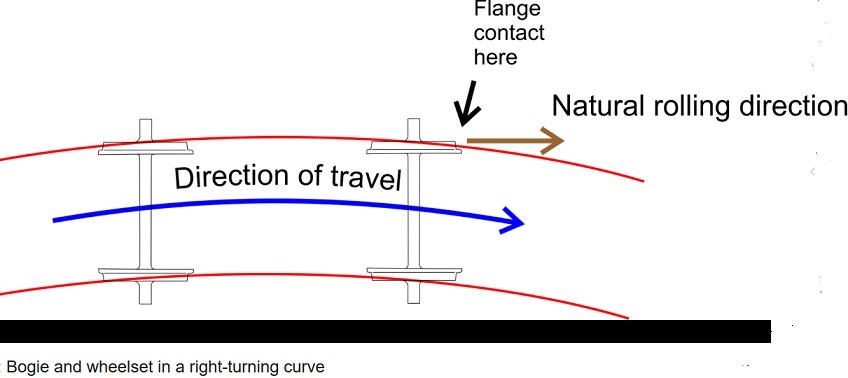

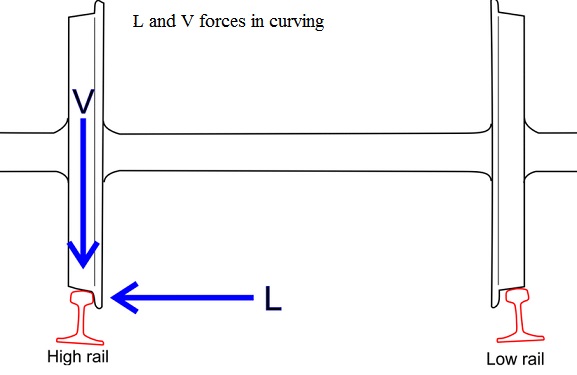

On a straight track, there is no outer rail and inner rail. When a track is curved to right, as you enter the curve, rail on right side is inner rail and rail on left side is outer rail. When a track is curved to left, as you enter the curve, rail on right side is outer rail and rail on left side is inner rail. The same terminology for right and left wheel.

______

______

Wheels:

_

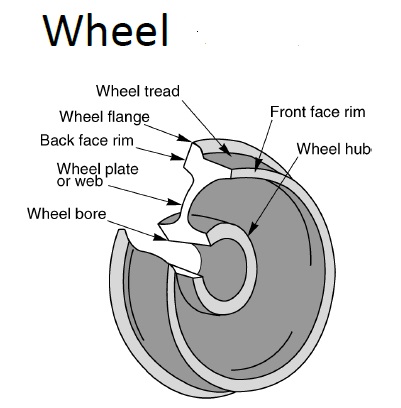

A train wheel or rail wheel is a type of wheel specially designed for use on rail tracks. A rolling component is typically pressed onto an axle and mounted directly on a rail car or locomotive or indirectly on a bogie (UK), also called a truck (North America). Wheels are cast or forged (wrought) and are heat-treated to have a specific hardness. New wheels are trued, using a lathe, to a specific profile before being pressed onto an axle. All wheel profiles need to be periodically monitored to ensure proper wheel-rail interface. Improperly trued wheels increase rolling resistance, reduce energy efficiency and may create unsafe operation. A railroad wheel typically consists of two main parts: the wheel itself, and the tire (or tyre) around the outside. A rail tire is usually made from steel, and is typically heated and pressed onto the wheel, where it remains firmly as it shrinks and cools. Monobloc wheels do not have encircling tires, while resilient rail wheels have a resilient material, such as rubber, between the wheel and tire.

_

The wheels of train perform the following three functions:

- The generic function of wheel i.e. carrying the car-body of the train.

- Prevention of derailment by incorporating flanges.

- Differential [vide infra].

_

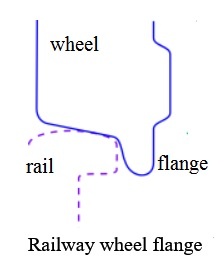

Wheel flange:

Flange is the inner section of a wheel that rides between the two rails. The angle between the wheel tread and flange is often specific to the rail to prevent wheel climb and possible derailments. The wheel flange is part of the wheel tire.

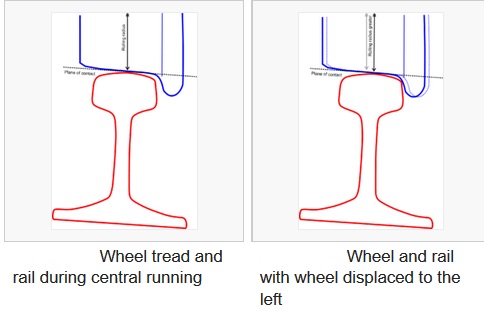

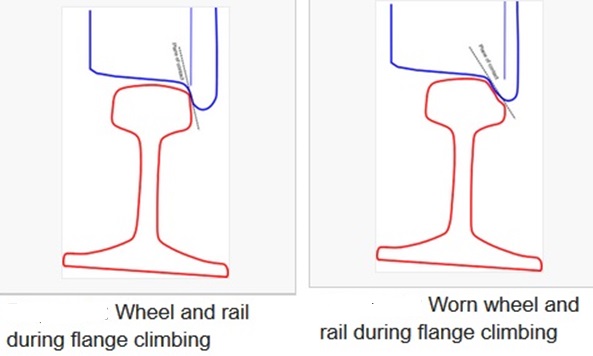

Most train wheels have a conical geometry, which is the primary means of keeping the train’s motion aligned with the track. Train wheels have a flange on one side to keep the wheels, and hence the train, running on the rails, when the limits of the geometry based alignment are reached, e.g. due to some emergency or defect. Some wheels have a cylindrical geometry, where flanges are essential to keep the train on the rail track.

_

Wheel tread:

It is the slightly conical section (often with a 1 in 20 slope) of a railroad wheel that is the primary contact point with the rail.

_

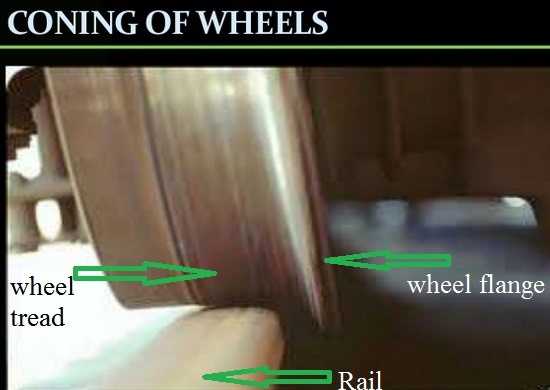

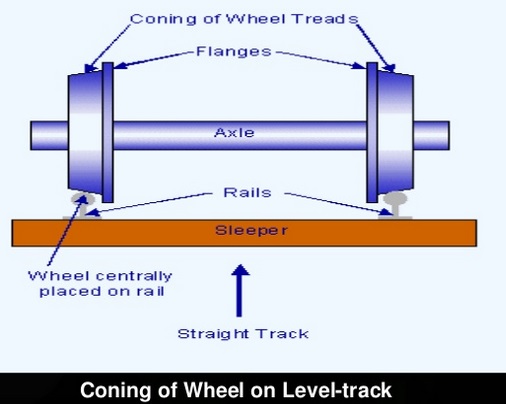

Coning of Wheels:

Wheel tread is present in the shape of cone with a slope of 1 in 20. When wheel are moving on track there is a chance of lateral movement. Without coning it will cause a sudden impact on the sides of rails. Coning of wheels is mainly done to maintain the vehicle in the central position w.r.t to the track. Due to coning of wheels, smooth riding possible, but the pressure on the inner edge may cause its wearing. Gauge widening happens sometimes. If base plates are not provided, sleepers under outer rails may damage. To minimize these effects, tilting of rails is done by the use of inclined base plates.

_

Wheel-rail interface:

It is the on-contact interaction between wheels and rails. The term is used in connection with the design and management of their interaction.

_

The most basic wheel:

- Coned wheel – 1/20 to 1/40

- Angular velocity constant for both discs

- Flanged wheel: flange on inside

- 7-10 mm flange clearance

- Single piece or tire-on-disc

- Made of steel by casting or forging

_

Role of conicity + constant angular velocity:

- Provides guidance on straight tracks

- Mechanism of motion gives rise to oscillation

- Differential action on curved tracks

- Easy manufacturing by casting

_

Role of inside flange:

- Final restraint on curves/unusuals

- Gives guidance on curves and changing tracks

- Stability through gravitational stiffness

_

Wheel failure zones:

Thermal cracks: Tread, Plate

Surface contact/rolling contact fatigue/spalling: Tread

Loose wheel: Hub, Bore

Excessive wear: Flange, tread

_

Wheel failure:

The most common type of wheel failure that may cause derailment is various out of roundness failures such as wheel flats, wheel tread wear and shelling, oval wheels, wheel profile failure etc. By themselves they seldom cause derailments, but wheel flats, wheel tread failures and out of roundness of wheels may increase the load on the bearing whilst wheel flats may also rupture rails, in particular under cold weather conditions. Wheel profile failures in combination with difficult track geometry are a common contributor to derailments. Wheel failures are much more pronounced in cold weather.

_

What would cause a steel wheel to wear out?

Many of the same things that damage car tires: Sudden stops. Sweeping curves. Lots of miles. While many of us change our car tires every 20,000 miles or so, Metro rail wheels can travel as far as 700,000 miles before they need to be replaced. Good thing because changing the wheels on a single rail car can take more than a week, depending on the design of the car. Re-profiling a steel wheel is the process of removing a thin layer of the wheel tread and flange with a large “wheel truing” machine. The truing machine restores the wheel’s roundness, tread taper and flange thickness to create good ride quality and steering.

_______

_______

Physics of train motion:

_

Train Resistance:

Train resistance is the force resisting the motion of train on track. When the tractive force developed by train is greater than the train resistance, then the train will start to accelerate. Specific resistance is equivalent to the train resistance per tonne i.e. train resistance / weight of train. The resistance offered by a train to move from stop is called Starting Train Resistance. The resistance offered by it to keep it moving at a specified speed is known as Rolling Train Resistance. In other words force needed to start a train from stationary position is starting resistance and force needed to keep a train moving at certain speed is rolling resistance. Starting resistance, appears at the time of starting, is to overcome the non-elastic effects of track & wheel surface, inertia and bearing friction. Starting Resistance depend upon the type of bearings, weight per axle & temperature of the bearing and drops rapidly as the train speed increases. It may be noted that the entire train does not start at a time. There is always some slackness in the coupling and by pushing the train backward, all the coupler are brought in slack position. While pulling in such condition, the entire train starts one by one with tightening of the couplers. There is no derived formula for starting resistance. Based on the different measurements, empirically Train and Loco Resistance are taken as 4 and 6 kg/tonne. Starting resistance is generally not much of a problem with the very large tractive effort available with modern diesel locomotives, except on steeper grades.

_

On straight & level track, train resistance consist of following resistances:

- Friction Resistance a.k.a. starting resistance

- Rolling Resistance

- Air Resistance

____

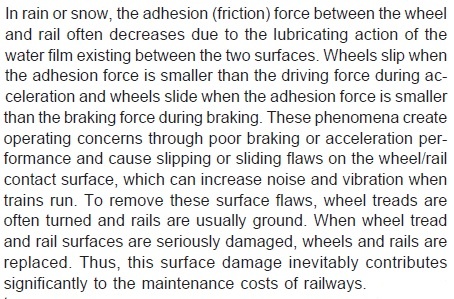

Rail adhesion:

Rail adhesion relies on the friction between a steel wheel and a steel rail. Adhesion is one of the most important term used in Railways parlance signifying the ability of efficient heavy haul and safe braking. Adhesion is caused by friction. Available adhesion between the driving wheels and the track depends on the weight per wheel, irregularities of contact surfaces, environmental conditions etc. and determine the force that can be applied before the wheels begin to slip or slide during traction or braking respectively. Adhesion limits the tractive and braking effort per traction and braking wheel respectively. Friction can be reduced when the rails are greasy, because of rain, oil or decomposing leaves which compact into a hard slippery lignin coating. The slipping and sliding phenomena are about stability in the front-rear direction. The stability in the left-right direction is guaranteed by the shape of the wheels. Adhesive percentage is defined as ratio expressed in percentage of tractive effort at wheel slip and vertical load on driving wheels.

_

Less friction = poor adhesion = wheels slide in braking (long min stopping distance)

Less friction = poor adhesion = wheels slip in traction (loss of hauling capacity)

_

Adhesion is caused by friction, with maximum tangential force produced by a driving wheel before slipping given by:

Fmax= coefficient of friction X Weight on wheel

For steel on steel, the coefficient of static friction can be as high as 0.78, under laboratory conditions, but typically on railways it is between 0.35 and 0.5, whilst under extreme conditions it can fall to as low as 0.05. Thus a 100-tonne locomotive could have a tractive effort of 350 kilonewtons, under the ideal conditions (assuming sufficient force can be produced by the engine), falling to a 50 kilonewtons under the worst conditions.

_

The coefficient of friction is not always the same for objects that are motionless and objects that are in motion; motionless objects often experience more friction than moving ones, requiring more force to put them in motion than to sustain them in motion.

- The static coefficient of friction is the coefficient of friction that applies to objects that are motionless.

- The kinetic or sliding coefficient of friction is the coefficient of friction that applies to objects that are in motion.

- Rolling coefficient of friction is different than sliding coefficient of friction.

__

Factors effecting adhesion:

- Condition of rail and wheel contact surface e.g. wet, dry. oily, slippery, etc.

- Type of track and sleeper density

- Rate of increase in torque applied to wheel.

_

Wheel slip:

Slipping happens when the force applied to move the wheels is larger than the friction between the wheel and the rails which can be resisted. Friction is needed to stop the wheel from slipping. The greatest effort is required from a locomotive when starting. At this time, if the engineer applies too much power to the wheels (i.e., for a steam locomotive, he opens the regulator too far) the turning force applied to the wheel will greatly exceed the opposing friction force affected by the surface of the rail, and the wheel will turn without being able to move the train forward. Wheel slip is not that bad a phenomena, it is speculated that maximum tractive effort during startup is obtained with a certain amount of wheel slip. Thus controllers have been designed for trains to monitor for wheel slip which permits a certain amount of slipping after which power to the wheels is automatically reduced. For Russian trains climbing up a grade, this slip is normally 1.5% to 2.5%. Slip (also known as creep) is normally roughly directly proportional to tractive effort. An exception is if the tractive effort is so high that the wheel is close to substantial slipping (more than just a few percent), then slip rapidly increases with tractive effort and is no longer linear. With a little higher applied tractive effort the wheel spins out of control and the adhesion drops resulting in the wheel spinning even faster. This is the type of slipping that is observable by eye—the slip of say 2% for traction is only observed by instruments. Such rapid slip due to a slippery rail reduces the tractive effort and hence haulage capacity and damages rail and wheel. Wheel slip was common with steam engines as they started to move due to the excessive torque often generated at low speed. Steam engines carried sand dispensing gear to increase traction at the start of motion.

Method to improve adhesion: – Clean rails regularly – Use sand while starting – Immediately cut off power if wheels slip.

__

Creep:

The behaviour of adhesion railways is determined by the forces arising between two surfaces in contact. This may appear trivially simple from a superficial glance but it becomes extremely complex when studied to the depth necessary to predict useful results. The first error to address is the assumption that wheels are round. A glance at the tyres of a parked car will immediately show that this is not true: the region in contact with the road is noticeably flattened, so that the wheel and road conform to each other over a region of contact. If this were not the case, the contact stress of a load being transferred through a point contact would be infinite. Rails and railway wheels are much stiffer than pneumatic tyres and tarmac but the same distortion takes place at the region of contact. Typically, the area of contact is elliptical, of the order of 15 mm across. The distortion is small and localised but the forces which arise from it are large. In addition to the distortion due to the weight, both wheel and rail distort when braking and accelerating forces are applied and when the vehicle is subjected to side forces. These tangential forces cause distortion in the region where they first come into contact, followed by a region of slippage. The net result is that, during traction, the wheel does not advance as far as would be expected from rolling contact but, during braking, it advances further. This mix of elastic distortion and local slipping is known as “creep” (not to be confused with the creep of materials under constant load).

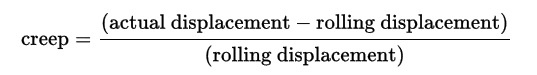

The definition of creep in this context is:

_

In analysing the dynamics of wheelsets and complete rail vehicles, the contact forces can be treated as linearly dependent on the creep (Kalker’s linear theory, valid for small creepage) or more advanced theories can be used from frictional contact mechanics. The forces which result in directional stability, propulsion and braking may all be traced to creep. It is present in a single wheelset and will accommodate the slight kinematic incompatibility introduced by coupling wheelsets together, without causing gross slippage, as was once feared. Provided the radius of turn is sufficiently great (as should be expected for express passenger services), two or three linked wheelsets should not present a problem. However, 10 drive wheels (5 main wheelsets) are usually associated with heavy freight locomotives.

__

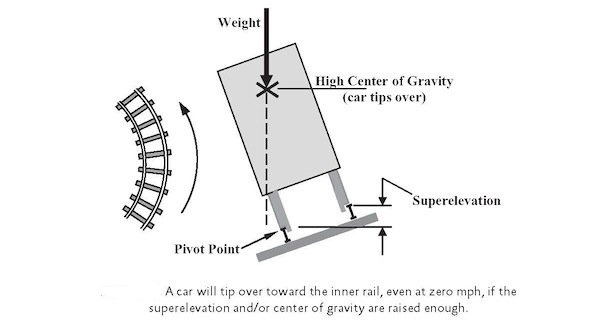

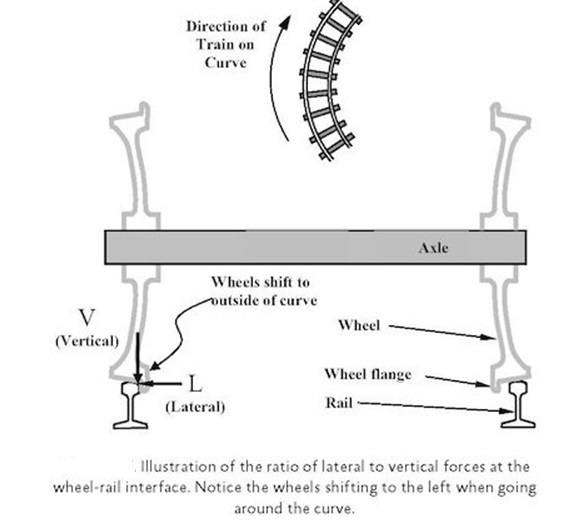

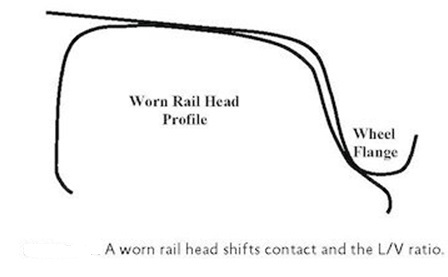

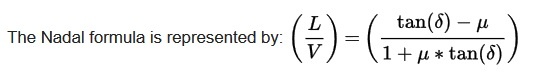

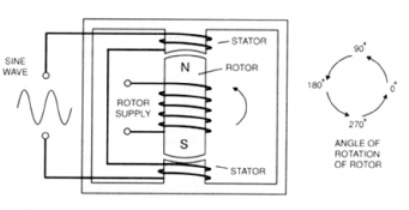

Rolling resistance: