Dr Rajiv Desai

An Educational Blog

3D PRINTING

3D Printing:

____

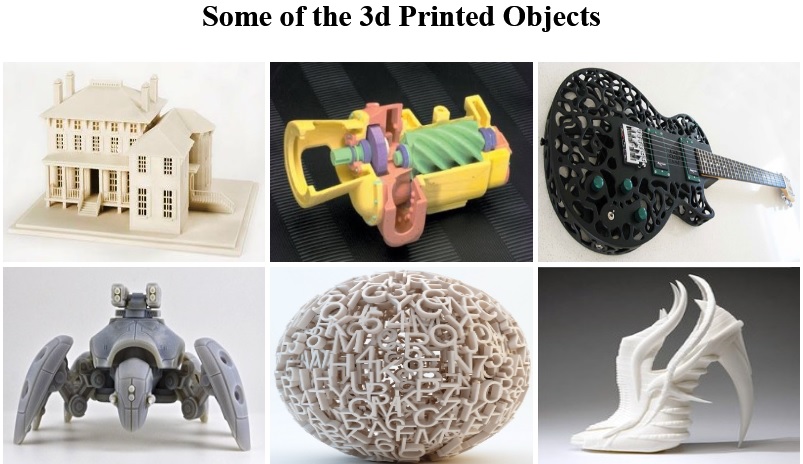

In reality 3D printing is quite slow as compared to the figure above!

____

Prologue:

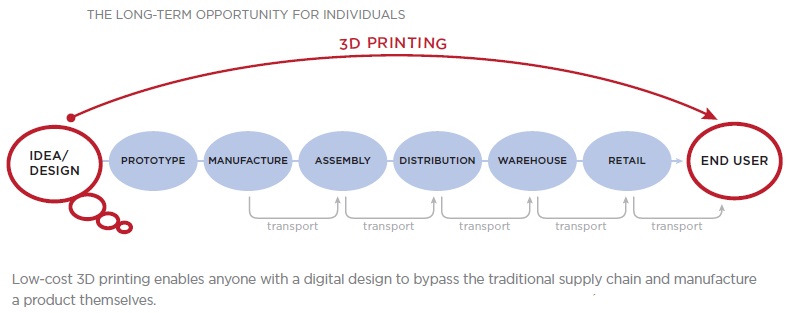

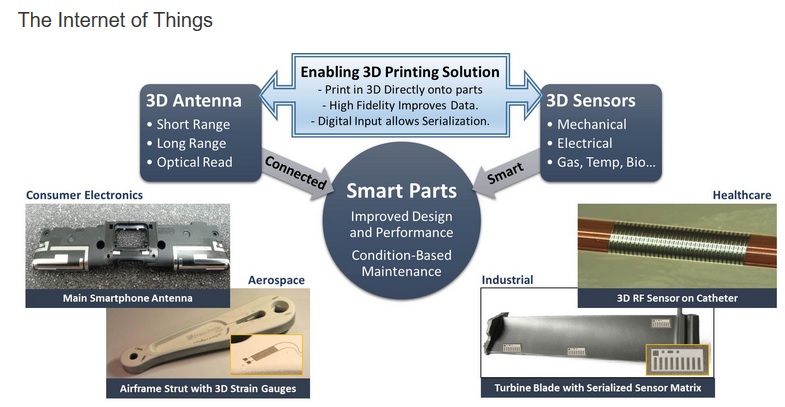

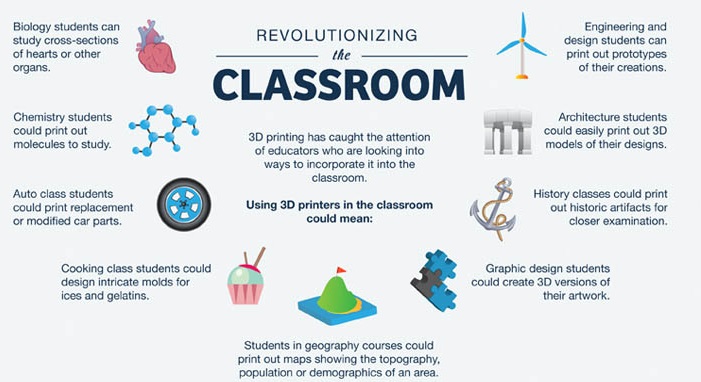

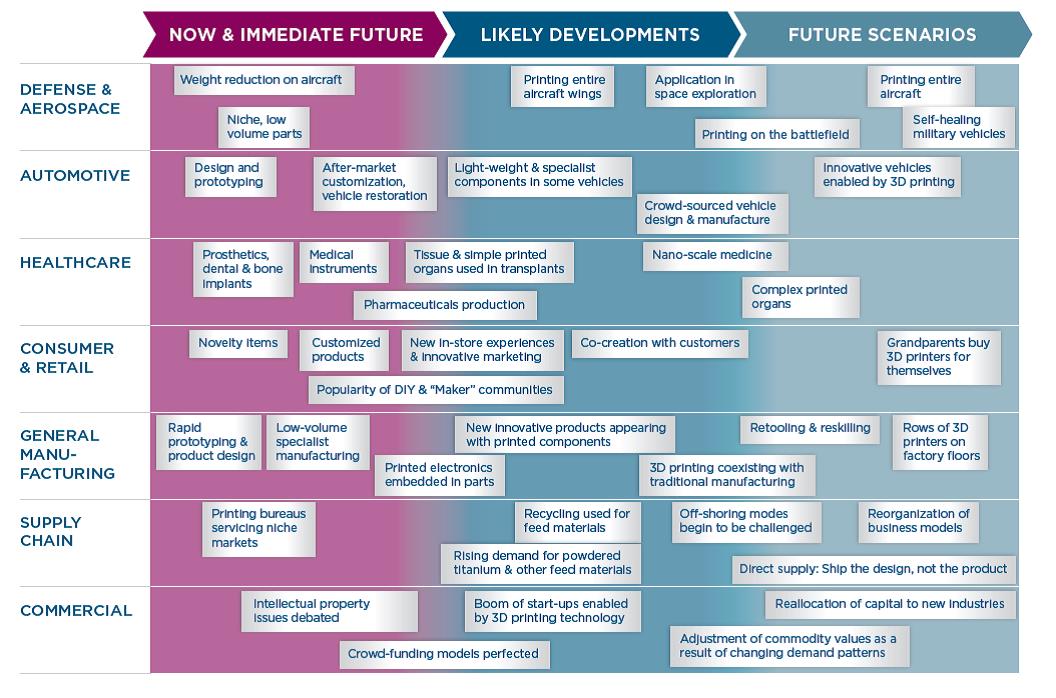

The First Industrial Revolution took place from the 18th to 19th centuries in Europe and America. It involved iron and textile industries, along with the development of the steam engine. The Second Industrial Revolution took place between 1870 and 1914, just before World War I and technological advances during this period included the telephone, light bulb, phonograph and the internal combustion engine. The Third Industrial Revolution, or the Digital Revolution, started in 1980s which refers to the advancement of technology from analog electronic and mechanical devices to the digital technology available today. Advancements during the Third Industrial Revolution include the personal computer, the internet, and information and communications technology (ICT). The Fourth Industrial Revolution builds on the Digital Revolution, representing new ways in which technology becomes embedded within societies and even the human body. The Fourth Industrial Revolution is marked by emerging technology breakthroughs in a number of fields, including robotics, artificial intelligence, nanotechnology, quantum computing, biotechnology, The Internet of Things, 3D printing and autonomous vehicles. I have discussed all the fields of Fourth Industrial Revolution in my previous articles except 3D printing. Today is the day of 3D printing. 3D printing is a technology which makes it possible to build real objects from virtual 3D objects. 3D printing, also called additive manufacturing is a process of making three-dimensional solid objects using a digital file. This is done by “cutting” the virtual object in 2D slices and printing the real object slice by slice. Slices are printed on top of each other and since each slice has a given thickness (e.g. 0.1 mm), the real object gains volume every time a slice is added. 3D printing is changing the way physical goods are developed, produced and distributed across all industries. Products that took weeks and months to design, prototype and manufacture now take a matter of minutes, with manufacturers enjoying a shorter time to market and lower cost base. 3D printing is portrayed as a manufacturing revolution. The question is not if but when companies need to consider 3D printing. Digital fabrication will allow individuals to design and produce tangible objects on demand wherever and whenever they need it. The revolution is not additive versus subtractive manufacturing; it is the ability to turn data into things and things into data.

_____

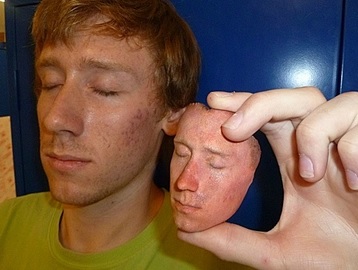

3D scanner makes digital file of your face. 3D printer constructs replica of your face.

____

3D Printing Glossary:

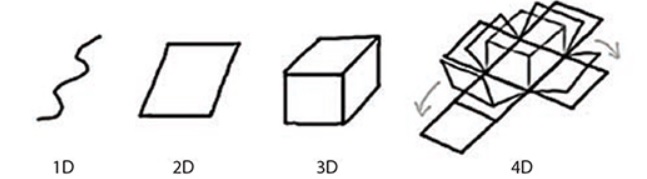

3D — having three dimensions: length (width), depth, and height.

Manufacturing –The making of things, usually on a large scale.

Prototype–A first or early model of some device, system or product that still needs to be perfected.

Additive — in 3D printing, the process of building an object by adding layer upon layer.

Subtractive — Creating an object by removing (subtracting) parts of a single block of material.

Thermoplastic — Plastic that becomes pliable upon heating then solid when cooled.

Plastic and Resin– Plastic is a form of resin. Natural resins are thick, sticky organic liquids that are insoluble in water. The sap of pine and other coniferous trees, often called pitch, is a resin. The materials we call plastics (polystyrene, ABS, acrylics, polyethylene, etc.) are synthetic resins in the form of long-chain polymers derived from (usually) petroleum. Resins are more of a natural origin directly derived from plant oozes whereas plastics are of a synthetic polymeric nature.

Triangle Geometry — The STL (stereolithography) file format describes 3D models as a set of triangles. Models also can be described with polygons or quad geometry.

Quad Geometry — Quad geometry is used to describe 3D models as four-sided polygons, for example, in polygon modelling and sculpting software. Printing a 3D model requires converting quad geometry to the triangle geometry used by the STL (stereolithography) file format.

CAD — Computer-Aided Design (CAD) software is used to create complete models, usually buildings structures and mechanical parts. CAD models are more precise than other types of models. CAD models also use NURBs to define curved edges. Polygon modelling and sculpture modelling software also are used to create 3D models for printing.

Polygon Modelling Software — Polygon modelling software creates models by connecting and combining polygon shapes at their edges. Polygon models rarely, if ever, use NURBs for curved edges. Instead, polygons are subdivided into new polygons to create the appearance of smooth round edges.

Sculpting Software — Sculpting programs can be used to create 3D models. They are polygon modelling software optimized to handle large numbers of polygons, for example, to create human shapes and round edges.

.STL — The STL (stereolithography) file format describes a 3D model as a set of triangles. STL files are converted to G-code which 3D printers use to print objects. Most 3D modelling software lets you save or export files in STL format. Otherwise, files are saved in OBJ (object) format and netfabb software is used to create the STL file from the OBJ format.

.OBJ — The OBJ file format is a common 3D model format used by modelling software. For 3D printing, OBJ files must be converted to STL file format and then G-code for printing.

G-code — a programming language used by machine tools, including 3D printers. A 3D model must be saved as an STL file format before it can be converted to G-code for printing.

Build Platform — in non-resin 3D printing, the flat level surface used as a base to create a three-dimensional object. Resin 3D printing uses a tank filled with resin instead of a build platform.

Build Volume — The maximum length, depth, and height a 3D printer can use to build an object. It is called Print Volume.

Extruder — A nozzle that takes thermoplastic wire or other material and deposits the material at a precise location with the print head.

FDM — Fused deposition modelling (FDM) is a process to use a fused material to deposit layer upon layer and create a three-dimensional object. FDM is trademarked. An alternative un-trademarked term is Fused Filament Fabrication (FFF).

Gantry — Larger non-desktop 3D printers use a steel frame made of connected beams to suspend the print head and other parts of the printer as objects are created.

NURB — Non-Rational Uniform Splines (NURBs) are a type of shape where the edges of the shape are splines (curves) controlled and adjusted by handles visible onscreen. You drag a handle to change the length and position of the curved spline edge.

ABS — Acrylonitrile butadiene styrene (ABS) is one type of thermoplastic used in 3D printing. It becomes soft and pliable when heated.

PLA — Polylactic acid (PLA) is a thermoplastic used in 3D printing as an alternative to ABS. Because it is made from sugars, PLA when heated can give off a sweet smell.

Slicing — The process of converting (slicing) a 3D model computer file into layers and then translate each layer into machine code used by the 3D printer to build the three-dimensional object.

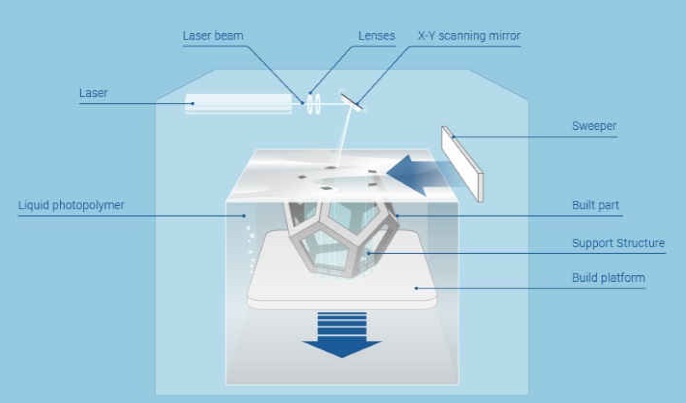

Stereolithography — An additive 3D printing process building layer upon layer by curing a resin with a laser.

subD — A subdivision (subD) surface is used in polygon modelling software to provide rounded edges to otherwise square surfaces, for example, a cube with rounded edges. The subD surface allows a specified set of edges to be subdivided into additional polygons to provide the rounded edge.

Watertight — A 3D object model is watertight when the printer can tell the inside from the outside of the model. If you filled up the model with water, no water would drain out.

_____

Three-dimensional (3D) printer –A machine that takes instructions from a computer program on where to lay down successive layers of some raw material to create a three-dimensional object.

Three-dimensional (3D) printing–The creation of a three-dimensional object with a machine that follows instructions from a computer program. The computer tells the printer where to lay down successive layers of some raw material, which can be plastic, metals, food or even living cells. 3-D printing is also called additive manufacturing.

_____

Triangle and polygon:

A polygon is a closed geometric figure whose sides are simple line segments. Each corner of a polygon where two sides intersect is called a vertex of the polygon. For example, a triangle is a polygon with 3 sides. There are also three vertices, one at each point. This is the simplest polygon, because you can’t construct one with just 1 or 2 sides. A polygon may be identified by the number of sides. A polygon with 4 sides is called a quadrilateral. A polygon of 5 sides is called a pentagon. A polygon of 8 sides is called an octagon. A polygon of 10 sides is called a decagon. Triangles are polygons, but polygons aren’t necessarily triangles.

_____

Abbreviations and synonyms:

3DP = 3 dimensional printing

AM = additive manufacturing = 3DP

FDM = Fused Deposition Modelling = PJP = plastic jet printing = FFM = fused filament method = FFF = fused filament fabrication

SLA = Stereolithography

CAD = Computer-aided design

STL file = Stereolithography file or Standard Triangle Language file or Standard Tessellation Language file

AMF file = Additive Manufacturing Format file

3MF file = 3D Manufacturing Format file

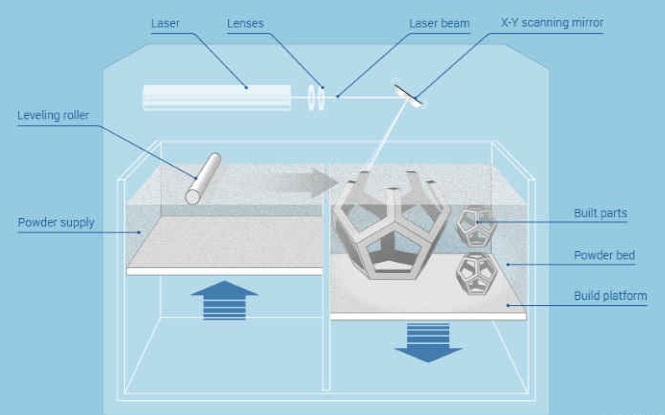

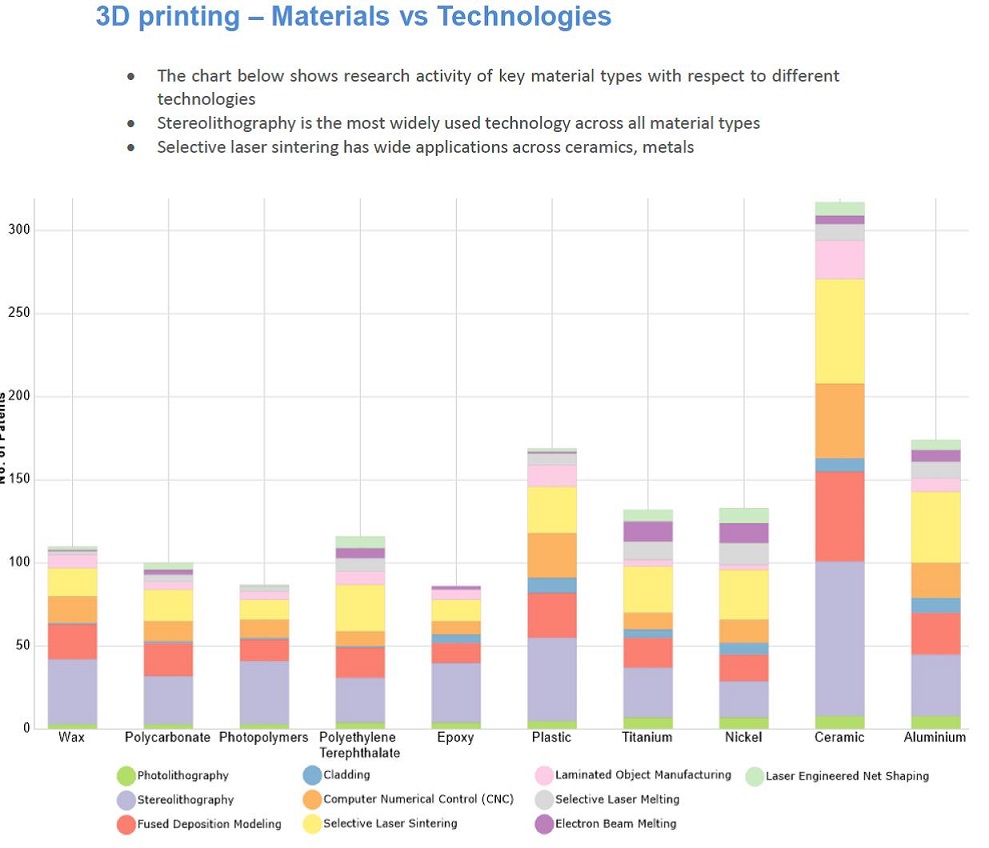

SLS= Selective Laser Sintering

DLP = Digital Light Processing

CLIP = Continuous Liquid Interface Production;

SLM = Selective Laser Melting

EBM = Electron Beam Melting

ABS = acrylonitrile butadiene styrene

PLA = polylactic acid or polylactide

CT = computed tomography

MRI = magnetic resonance imaging

PDMS = Polydimethylsiloxane

PE = Polyethylene

PP = Polypropylene

PVC = Polyvinyl chloride

PS = Polystyrene

PET = Polyethylene terephthalate

PUR = Polyurethane

PVA = Polyvinyl alcohol

HDPE = High-density polyethylene

PETT = Polyethylene terephthalate

RP = Rapid Prototyping

IoT = internet of things

_____

_____

Introduction to 3D printing:

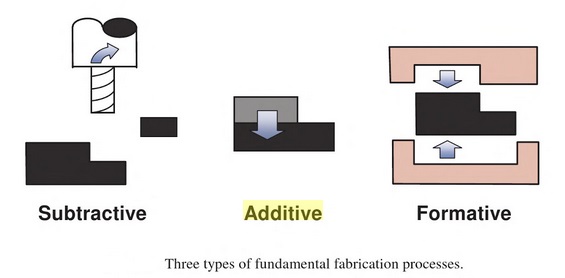

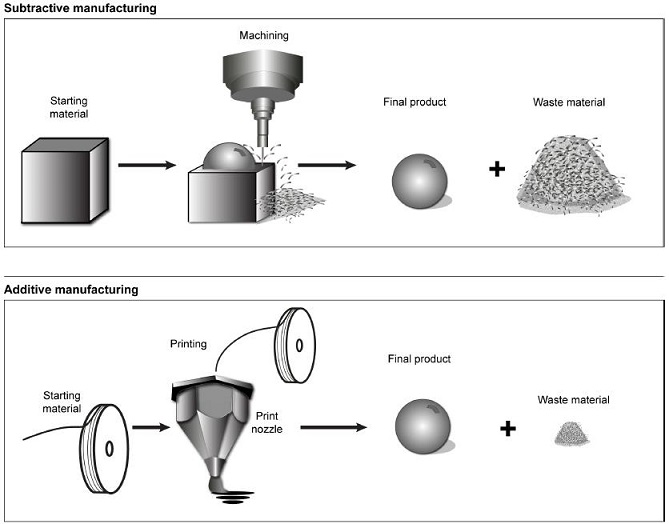

3D printing or additive manufacturing is a process of making a three-dimensional solid object of virtually any shape from a digital model. Successive layers of material are laid down in different shapes. Traditional machining techniques rely on the removal of material by methods such as cutting or drilling whereas 3D printing layers are added successively. Thus it uses a layering technique where an object is constructed layer by layer until the complete object is manufactured. In this way 3D printing moves us away from the mass production line to a one-off customizable production. You can literally make any object from a house to a bar of chocolate, so to say. The initial 3D printers were used in the 1980s where a pattern submerged in a liquid polymer would be traced by a computer. The traced pattern hardened into a layer, thanks to the laser, and that was how you built an object out of plastic. Since then tremendous progress has been made in additive manufacturing such that material extrusion is now used. By this method, an object is built out of matter that is pushed from a mechanical head like the way an inkjet printers extrudes ink onto paper. Interestingly, the cost of acquiring 3D printers has been decreasing with the advancement of technology. Domestic usage of 3D printers has been on the rise with the average cost ranging from a few hundreds of dollars going up. However, one major drawback is that it requires expertise to print 3D objects. In fact, it requires a competent person to make both the digital file and the final printing. Commercial usage of 3D printers has been on the increase too in sectors such as the automotive industry and aero-space engineering. Spare parts, for example, are being made in the automotive and aero-space industry leading to improved economies of scale. 3D printing is changing how the production line in industries works which made some analysts to dub the emergence of 3D printers as another Industrial revolution. 3D printing has also had a tremendous usage in the field of medicine; from the field of Bionics, to Prosthetics to Digital Dentistry. Inevitably, this is positively affecting and changing every aspect of medicine. Most of the work is still in its exploratory phase but pundits predict medicine of tomorrow is going to be revolutionized by the integration of 3D printing as a tool.

_

2D to 3D printing:

Can you imagine writing your essay with a quill and ink? How about using a typewriter that doesn’t have spell check? Today, you can use a word processor and simply print out your essay when it’s finished. Printers have become so commonplace that you’ll find them in many classrooms and homes. Today’s models are relatively inexpensive and can even print photograph-quality pictures in color. For years, they’ve been limited to two dimensions. All of that changed, though, when 3D printing was invented. With the regular printers, we print the image, text or other graphics on a piece of paper. The file required for printing these diagrams also gives us the imagery in 2-dimension. But for 3D printers, we need a 3-dimensional representation. For this purpose, we use CAD (Computer Aided Design) diagrams. These diagrams are produced in CAD tools. For example, software like AutoCAD 3D or Microsoft Visio or printer customized software could be helpful in making these diagrams. If one doesn’t know how to render these diagrams, a huge library of thousands of such 3D designs are available on the internet for free.

_

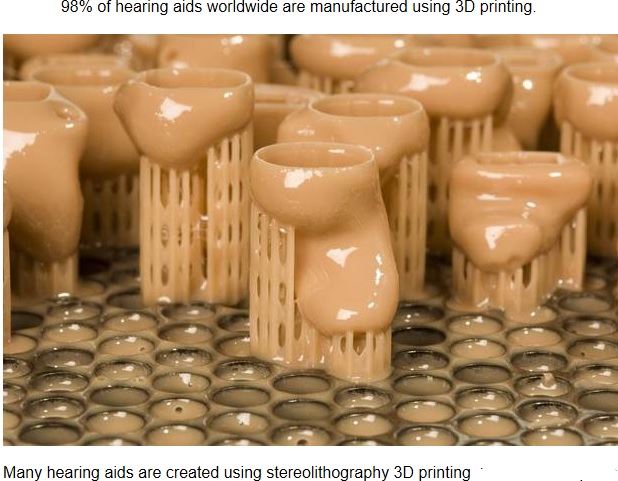

A 3D printer isn’t anything like a regular printer, however. Instead of printing a simple text document on a single piece of paper, 3D printers can “print” a real three-dimensional object! The technology behind 3D printing has actually been around for several years. Back in the mid-1980s, Chuck Hull invented a process known as solid imaging or stereolithography. Hull’s work set the stage for the amazing leaps this technology would take in subsequent years. The process of 3D printing starts with a design created with computer-aided design (CAD) or animation modelling software. The design could be for a scale model of a new engine part, a simple toy action figure, or even a prosthetic limb. Once you have your digital blueprint created, you can send it to a 3D printer. Unlike an inkjet printer that sprays ink onto a piece of paper, 3D printers use similar mechanical print heads to spray or squeeze raw material, including rubber, plastic, paper, metal, or other composite materials, onto a platform. 3D printing is an additive manufacturing process. That means that it creates a three-dimensional object in layers from the bottom up. For example, to build a simple plastic toy action figure, a 3D printer would heat thin filaments of plastic and squeeze it onto a platform layer after layer, slowly building the three-dimensional toy from the bottom up. To heat the materials they extrude, 3D printers often use lasers or similar devices. 3D printers can even create metal objects by heating metal dust with lasers. The amount of time it takes to “print” a three-dimensional object can vary from a few hours to several days, depending upon how complex it is. 3D printing has become extremely popular in manufacturing sectors, where new prototypes can be 3D printed in a fraction of the time — and at a fraction of the cost — of making traditional wood or metal prototypes. 3D printing technology has thus streamlined and economized the manufacturing process in many industries. The future appears bright for 3D printing technology. There are particularly-exciting possibilities for the medical field, where 3D printing may be used to create everything from hearing aids to prosthetic limbs. NASA has even begun testing 3D printers that could be used on space missions to allow astronauts to print things they need on demand!

_

Why is it called printing?

If you look closely (with a microscope) at a page of text from your home printer, you’ll see the letters don’t just stain the paper, they’re actually sitting slightly on top of the surface of the page. In theory, if you printed over that same page a few thousand times, eventually the ink would build up enough layers on top of each other to create a solid 3D model of each letter. That idea of building a physical form out of tiny layers is how the first 3D printers worked.

_

_

Digital Material Convergence:

We are witness to escalating movement towards the materialization of digital information that encompasses and crosses multiple areas, including recent innovations in ubiquitous and physical computing, open source hardware, and digital manufacturing, in concert with ongoing advances in social networking and online communities. In the spirit of other forms of media convergence, previously unseen combinations between digital and physical production are emerging that encourage unprecedented control over material and symbolic landscapes. Increasingly, groups possessing various levels of technical expertise are able to simultaneously make and share both things (“material”) and knowledge (“immaterial”) through newly conceived digitally mediated practices. As forecasted by Gershenfeld (2005), technologies such as computer numerically controlled (CNC) mills, laser cutters and engravers, as well as ‘3D printers’ that were once the exclusive domain of large industry are now migrating from the factory to the desktop. If we look at how readily other forms of digital development such as document publishing, digital photo manipulation and Web site creation moved from expert to lay populations, it can be expected that a similar move will occur with digitally designed and physically manufactured media as well. Indicative of the increasing porosity between the digital and the material, a revolution in desktop digital fabrication is at least partially underway.

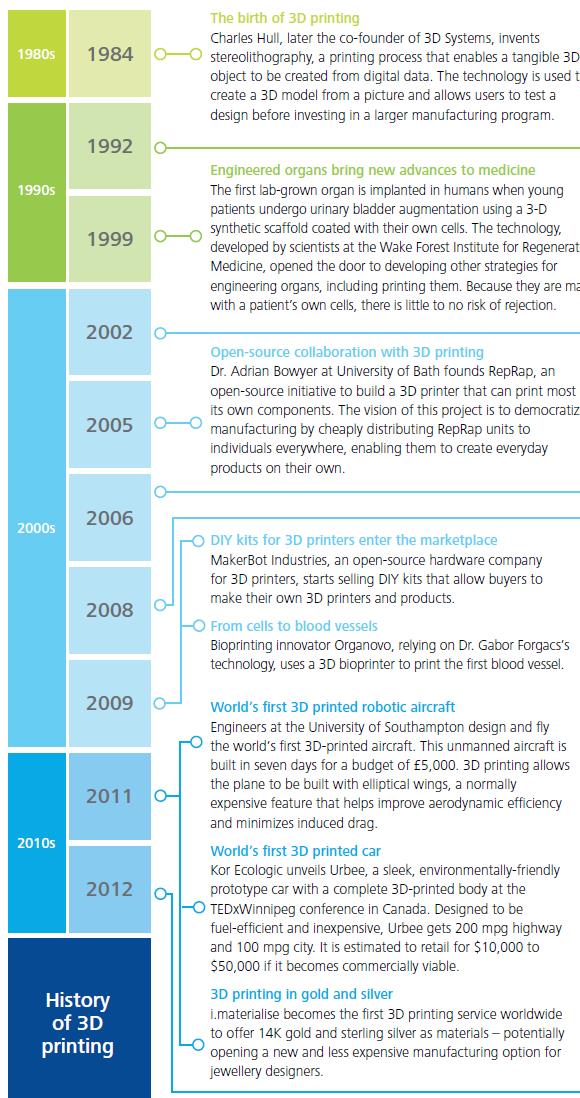

___

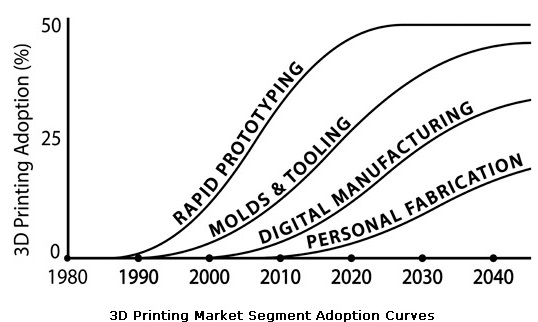

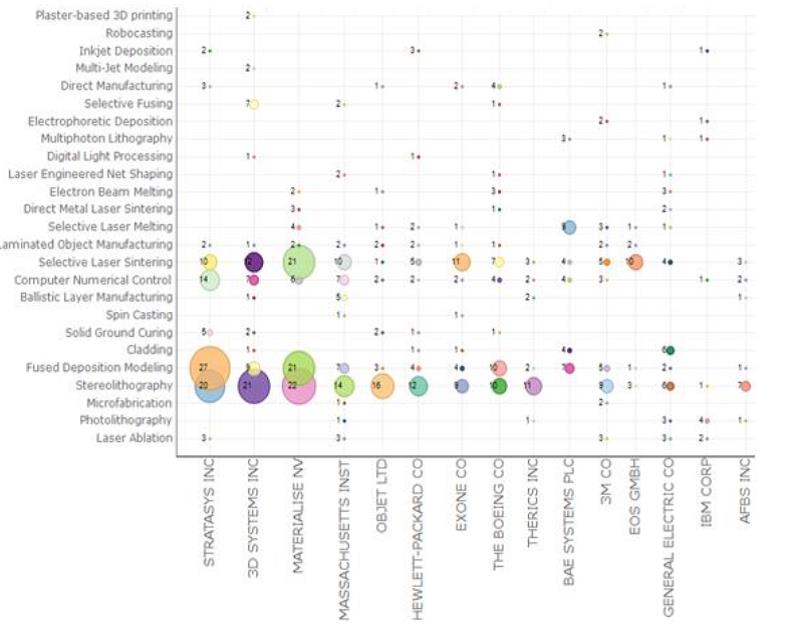

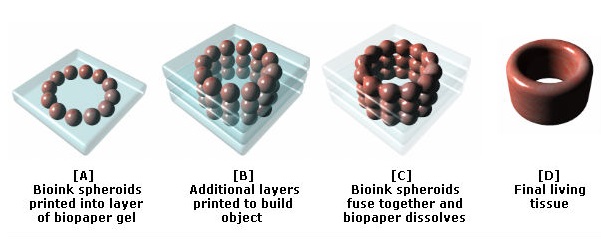

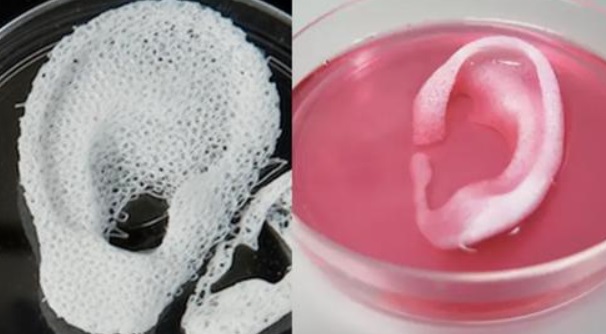

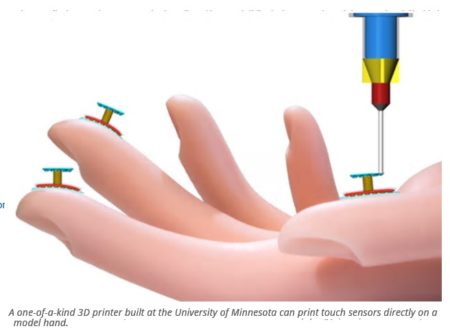

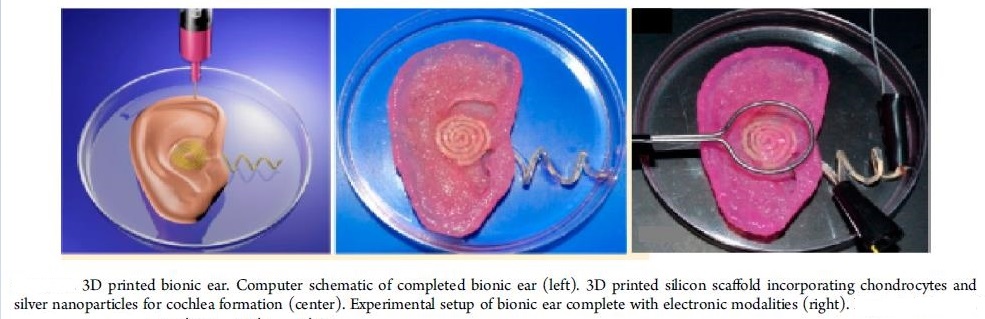

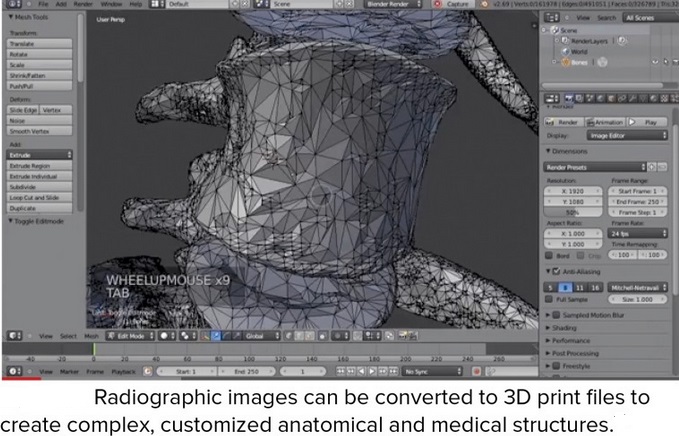

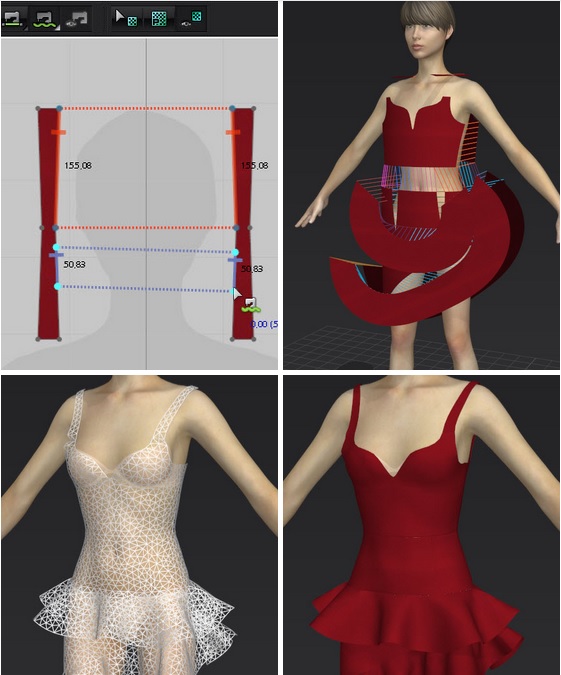

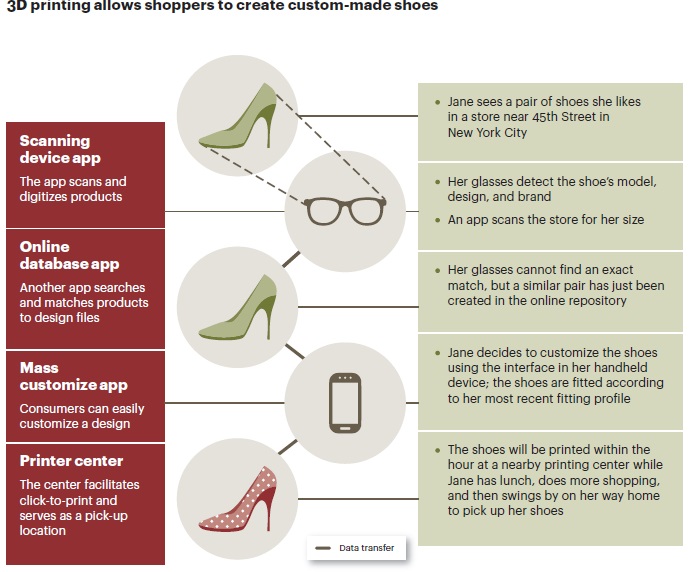

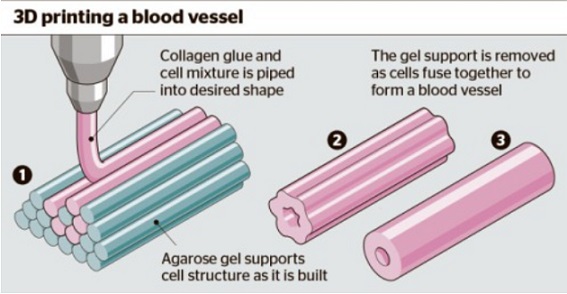

Three-dimensional (3D) printing technology, also called additive manufacturing (AM), has recently come into the spotlight because of its potential high-impact implementation in applications ranging from personal tools to aerospace equipment. Other terms used as synonyms, hyponyms, and hypernyms to additive manufacturing include layered fabrication, desktop manufacturing, rapid manufacturing [a successor to rapid prototyping], and on-demand manufacturing (which echoes on-demand printing). Even though 3D printing technology has only recently emerged as a hot topic, its history can be traced back to 1983 when the first 3D printer was created by Charles W. Hull, co-founder of 3D Systems. Since then, new and wide-ranging applications and markets for 3D printers have appeared rapidly, especially with the expiration of a number of core 3D printing patents owned by Stratasys Inc. and 3D Systems Inc. Users can easily build or modify 3D printers by themselves or take advantage of the rapidly growing availability of inexpensive 3D printers. The recent availability of highly capable 3D design software and 3D design websites (e.g., Shapeway and Thingiverse) allows the sharing of user-created free 3D digital design files or models, leading to more access to 3D printers and additional proliferation of 3D printing technology. As 3D printing becomes more than just a simple production process, it has come to support a convergence of technologies and applications such as sports equipment, food packaging, and jewellery, as well as products in the high tech fields of aerospace, medicine, architecture, education, automotive industry, military support, and others. At the 2016 New York Fashion Week, two unique 3D printed dresses were unveiled. These masterpieces were produced through a collaboration between fashion designers and the 3D printing company, Stratasys. The complex designs (e.g., mixing a variety of interlocking weaves, biomimicking natural animal textures) and cutting-edge material (e.g., nano-enhanced elastomeric 3D printing material) gave the dresses durability and flexibility. The area of regenerative medicine has also achieved impressive applications within the 3D printing field. Dr. Anthony Atala’s team from the Wake Forest Institute for Regenerative Medicine has successfully used 3D printing technology to fabricate living organs and tissue (including muscle structures, and bone and ear tissue). These bioprinted body parts are capable of generating functional replacement tissue. NASA has also been implementing 3D printing techniques and 3D printers to develop materials that allow astronauts to repair or replace essential parts and build structures in space. NASA recently collaborated with researchers at Washington State University to fabricate a replica of a moon rock using raw lunar regolith simulant and 3D laser printing technology. The assembly of modular construction materials using giant 3D printers for use in the housing industry has gained significant interest, especially for poorer countries, during natural disasters, or sudden emergencies. Some 3D companies have succeeded in building houses or bridges with cement, sand, or concrete materials.

__

A Basic Definition of 3D Printing:

We all know what printing is so let’s begin with the 3D part of 3D printing. 3D is shorthand for three-dimensional. When you print a page on a printer, there are only two dimensions: the front of the page and the back of the page. Three-dimensional printing adds a third dimension, volume. 3D printing uses a printer to create three-dimensional objects, for example, a cup or Yoda doll or phone case.

3D printing has these qualities:

- Objects are created by adding or depositing layers of material, not subtracting or cutting out pieces from a block of material.

- Because objects are created by adding layers, the computer file with details about your model must be converted into slices the printer will create layer by layer.

- Printing a three-dimensional object can take hours or days to complete, depending on the complexity and size of the object.

- Cost is based on materials used, among other factors. In contrast, if you buy a piece of wood then cut out pieces to create your object you pay for the original piece of wood.

_

3D Printing is the process of making a physical object from a three-dimensional digital model, typically by laying down many thin layers of a material in succession. “3D printing” or “Additive Manufacturing” takes digital input in the form of Computer Aided Design (CAD) model and creates solid, three dimensional parts through an additive, layer by layer process. 3D printing refers to processes used to create a three-dimensional object in which layers of material are formed under computer control to create an object. The technology of printing physical 3D objects from digital data using vertical axis manufacturing process is called “additive manufacturing.” The amount of material, the rotation of the platform and the design of the object is administered in a computer controlled environment. Objects can be of almost any shape or geometry and are produced using digital model data from a 3D model or another electronic data source such as an Additive Manufacturing File (AMF) file. Additive Manufacturing File Format (AMF) is an open standard for describing objects for additive manufacturing processes such as 3D printing. The official ISO/ASTM 52915:2013 standard is an XML-based format designed to allow any computer-aided design software to describe the shape and composition of any 3D object to be fabricated on any 3D printer. Unlike its predecessor STL format, AMF has native support for color, materials, lattices, and constellations. This technology allows for complex shape, size and dimensions which are not easily or economically available using traditional manufacturing tooling methods. 3D printing services allows low cost production of highly specific, low volume products or mass markets quicker. Remove unwanted restrictions to your designs, produce prototypes as one unit or pre-built unit assembly to aid in mass manufacturing.

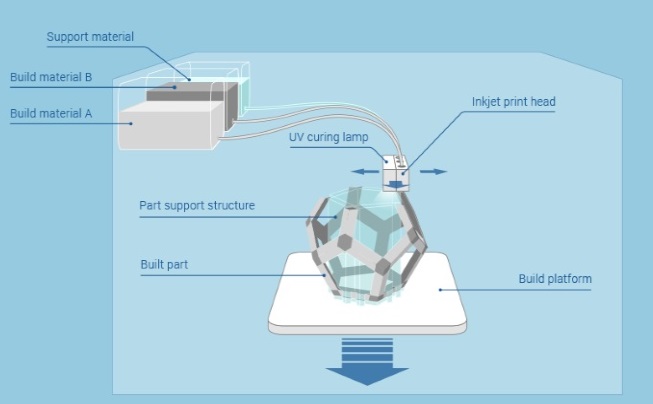

___

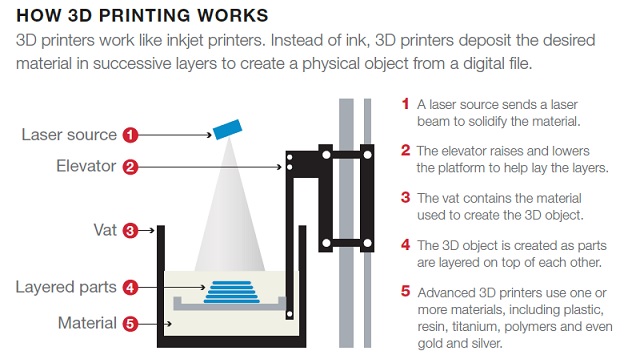

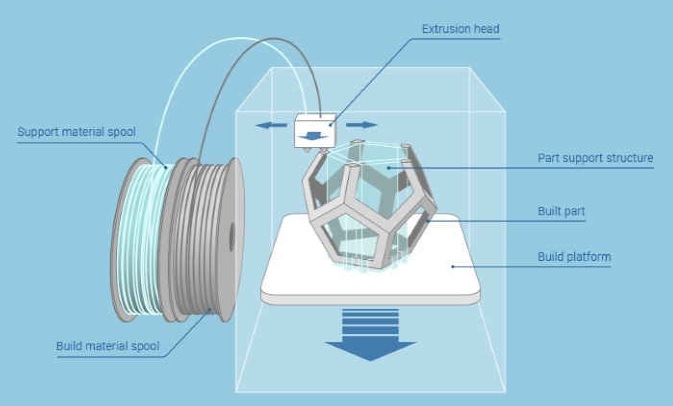

At a high level, a 3D printer takes material, usually plastic wrapped on a spool, heats the material, and then fuses the material layer by layer to build a three-dimensional object. The material is extruded, or pushed out and deposited. Precision is critical for 3D printers. The print head, pulleys, and extruder hardware must be aligned, as well as software dimensions translated to the correct real world dimensions used by the printer hardware. The Printrbot printer is a low end printer you can build yourself to understand how all the pieces of a 3D printer fit together and work. Most people, however, use a pre-built printer where they adjust the location of the print head and build platform, as well as test the extruder heads emit the material used to print. There are at least two kinds of additive 3D printing, resin and non-resin. Printing objects with resin uses laser technology to solidify layer by layer to create objects. It often is extremely costly and uses light and chemicals to cure the object. However, the results are more precise than non-resin printing. When people talk about 3D printing, they’re mostly talking about non-resin printing. Instead of resin, lasers, and chemicals; non-resin printing uses plastic, food, ceramics, or other material and adds layer upon layer to create an object.

_

The invention of 3D printing target 2 things: reduce time to get the first version of a product and emancipate many constraints that are not possible with traditional production methods. For example, with 3D printing, it is possible to print complex geometric shapes and interlocking parts that require no assembly. It is also possible to produce single objects, in small quantities, at low cost and fast delivery. This technology also helps in the reduction of production-related material loss. 3D Printing can produce different objects without creating specific tooling or even using several tools. This is how 3D Printing helps increasing flexibility in the production flow and helps reducing industrial expenses. Since there’s no need to build dedicated production line, it helps to save time: 3D Printing enables to innovate faster and mechanize faster. Since 3D Printing makes a replica of the 3D files one by one, so economies of scale can’t be realized when the same file is produced several time: this is clearly different from series manufacturing methods which aim for producing millions of units of the same objects. On the contrary, 3D Printing is the perfect method for on-demand and customization needs. Finally 3D Printing gives to everyone the power to manufacture objects only when they are needed or desired. It’s a fantastic process for the creative ones who wish to make something out of their imagination. 3D Printing enables in this way many people to produce and sell their creations by skipping traditional edition and distribution networks. 3D Printing is also useful to reproduce objects that are no longer on sale, for instance in order to repair an old bike for which spare parts are discontinued.

_

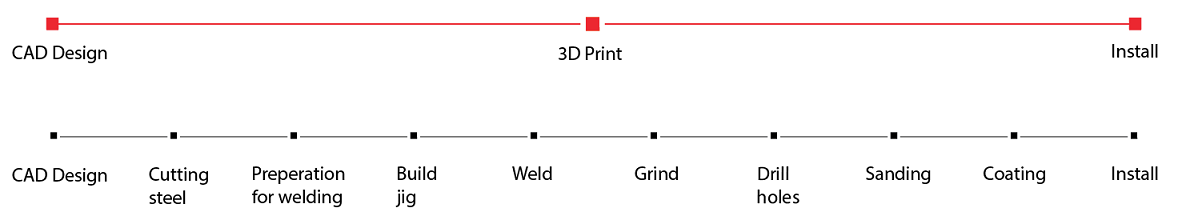

3D printing brings a revolutionary approach to manufacturing through two key advantages: Shorter lead time and design freedom:

Lead Time:

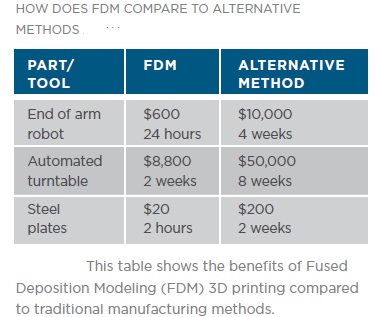

It’s a little hard to appreciate manufacturing before 3D printing. The way we have approached prototyping for the past three decades might even be considered a luxury when compared with prototyping prior to 3D printing. Today, 3D printing an early phase design and re-printing it overnight is feasible and affordable thanks to rapid prototyping or 3D printing platforms like PolyJet and Stereolithography. 3D printing a final product in just one to two days is feasible with multiple 3D printing technologies, such as Laser Sintering, Fused Deposition Modeling and Direct Metal Laser Sintering. However, prior to these quick-turn prototyping and production manufacturing processes, bringing an idea into physicality was an involved and costly process and there often wasn’t room or time to re-prototype frequently or make multiple design adjustments.

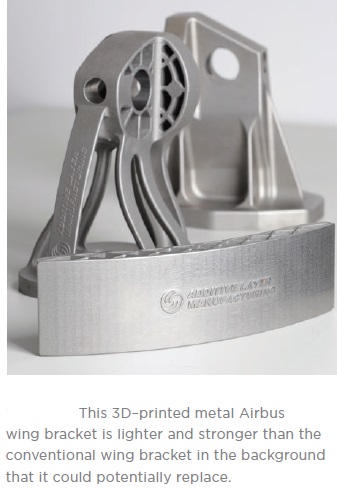

Design Freedom:

Traditionally, designers and engineers have relied heavily on the manufacturing process to dictate the end design. Involved conventional manufacturing processes like CNC machining have inherent strict limitations on assembly rules, manufacturability and overall feasibility. Stepping outside of design practices for these conventional manufacturing processes directly results in increased cost and labor. However, sticking to the design rules of the past inevitably results in stunted innovation growth. Additive manufacturing, or 3D printing, has opened doors previously unimaginable to designers and engineers because it doesn’t rely on the same design and manufacturing constraints as conventional manufacturing. Through 3D printing, free-flowing, organic and intricate designs are seamlessly executed while maintaining strength in ways impossible via any other manufacturing process. An excellent case example of the design freedom of 3D printing comes straight from NASA. NASA’s Marshall Space Flight Center was able to transform a part that previously contained 150+ parts and, through 3D printing, consolidated the whole design into one continuous unit! Design freedom in 3D printing is considered “zero-cost” because of the layering process. Design features are seamlessly integrated within each cross-section as the part builds, eliminating the need for tooling, labor intensive assembly, and reducing time and part count to result in significant cost savings.

_

What can you do with 3D printing?

The possibilities of 3D printers are endless, and they’re now becoming a commonplace tool in fields like engineering, product design, manufacturing and architecture. Here are some typical uses:

- Custom models

Create customized products that are completely tailored to your needs in terms of size and shape. Make something that wouldn’t be possible with any other kind of technology.

- Fast prototyping

3D printing makes it possible to quickly create a model or prototype, helping engineers, designers and companies to get iterative feedback on their designs in a short time.

- Complex geometry

Models that are difficult to even imagine can be created in a 3D printer with ease. These models are great at educating others about complex geometry in an interesting and useful way.

__

3D printing is transforming technology in several ways.

- First, 3D printing technology is increasingly allowing localized production of industrial and commercial goods.

- Second, it allows for intricately customized prints from specialized organs to custom houses.

- Third, it allows for rapid prototyping of nanotechnology thus opening opportunities for significant technological advances.

- Lastly, it allows for computer-based goal-directed design allowing for unlimited geometric and material complexity.

__

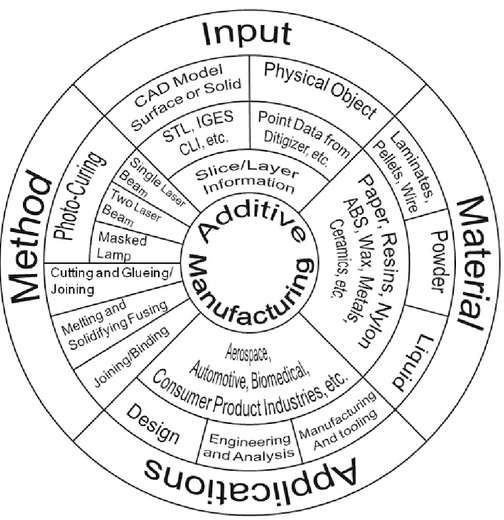

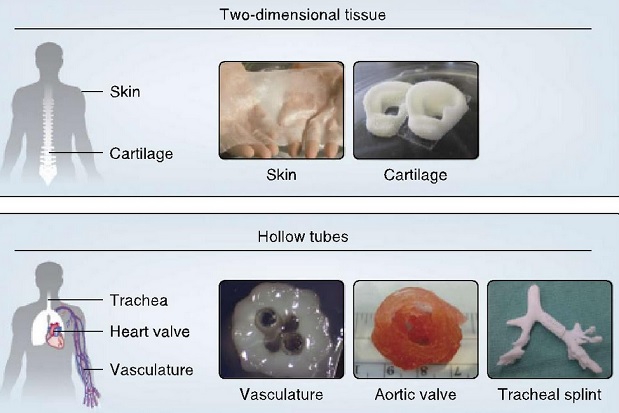

Applications of 3D printing can be broadly categorized into four categories.

- First, manufacturing applications include rapid prototyping, mass customization of products, rapid manufacturing etc.

- Industrial applications include manufacture of industrial parts from aerospace to automotives to construction to firearms.

- Tissue fabrication, implants, prosthetic limb manufacture, and pill manufacture mostly make up medical applications.

- Socio-cultural applications include artwork, fashion, preservation of cultural heritage etc.

______

______

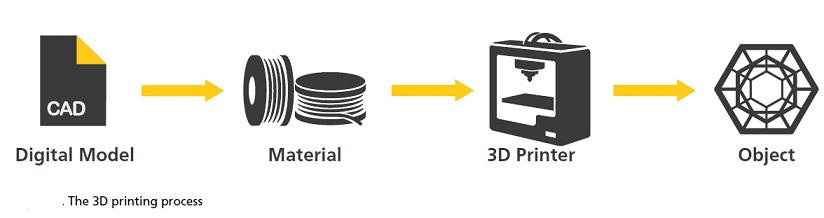

The 3D Printing Process:

_

Printing a three-dimensional model is more complicated than opening up Microsoft Word and printing to your 2D printer. At a high level, to create a 3D model you follow these steps:

- Find a model or create a model with Blendr, SketchUp, or OpenSCAD software.

- Prepare your model for printing, for example, ensuring the model is watertight with no gaps.

- Create an STL file which converts your model into code the 3D printer understands, using Netfabb, Meshlab, or similar software.

- Print your 3D model, adjusting the printer as needed. 3D Printing uses software that slices the 3D model into layers (0.1mm thick or less in most cases). Each layer is then traced onto the build plate by the printer, once the pattern is completed, the build plate is lowered and the next layer is added on top of the previous one.

You might do some or all of these steps, depending on whether or not you have a 3D printer or use a printing service. There’s also lots of help if you use a printing service or find help online.

_

_

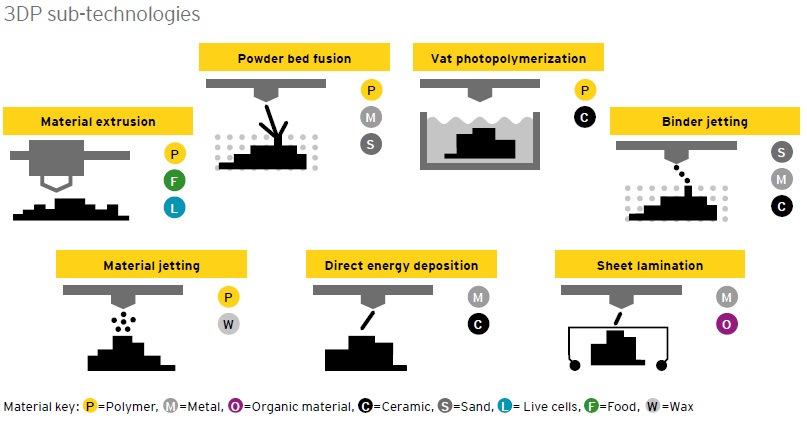

With 3D printing, an object can be made by using the following methods:

- Extruding,

- Sintering, or

- Curing.

Extruding involves using continuous filament of a thermoplastic material as the feedstock. Sintering is an additive manufacturing procedure that uses a laser as a power source. Curing uses a liquid resin as the feed material and the object is built layer-by-layer and cured; this process takes place slowly.

_

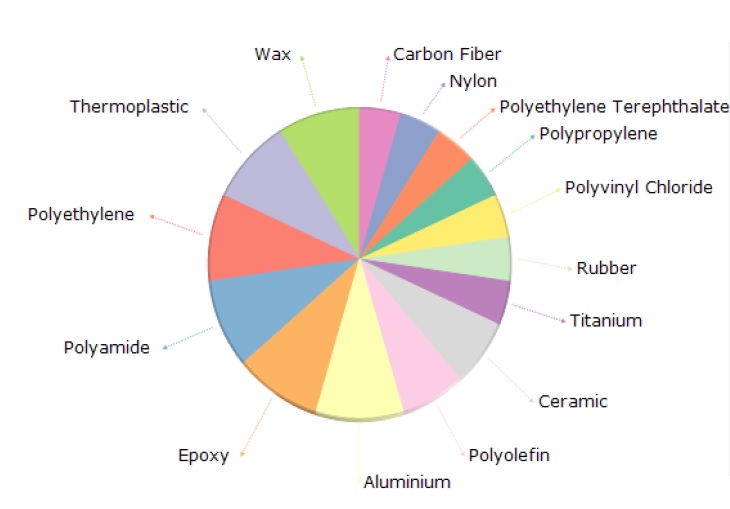

Materials used in 3D Printing:

Many different materials can be used for 3D printing, such as ABS/PLA plastic, polyamide (nylon), glass filled polyamide, silver, titanium, steel, wax, photopolymers (UV resins) and polycarbonate. Resin 3D printers use custom formulated plastic resin poured into a tank. The resin is light sensitive and hardens when laser light heats a spot within the resin. Non-resin 3D printers use mostly ABS and/or PLA plastic which becomes pliable when heated then solid. And newer printers can print ceramics or with food materials

_

Overview of the type of material the technologies work with and how the parts are built out of this material:

- Polymerization means that parts are built through a UV-light activated polymerization of a chemically reactive liquid material.

- Bonding agent means that powder material is glued together through a liquid bonding agent.

- Melting means that material is melted together.

_

Contrary to popular belief, there isn’t a one-size-fits-all approach to 3D printing. Depending on the part characteristics required, additive manufacturing technologies are either used to directly produce the parts or in indirect processes in combination with traditional manufacturing techniques. Depending on the requirements, these technologies are either used alone or can be combined with other manufacturing techniques:

- Direct processes:

–One stage process: The part is directly produced with the additive manufacturing machine. There are post-processes applied in order to improve tolerances or surface finish.

–Multi-stage process: A “green” part is produced with the additive manufacturing technology which is then going into further processes. For instance, binder jetting is used to produce green metal parts (where metal powder is glued together) which are then going into a sinter process and are infiltrated afterwards.

- Indirect processes:

Additive manufacturing can be combined with traditional manufacturing. For instance, master patterns are made with 3D printing technologies which are then used for investment casting of final parts.

_

Process chain:

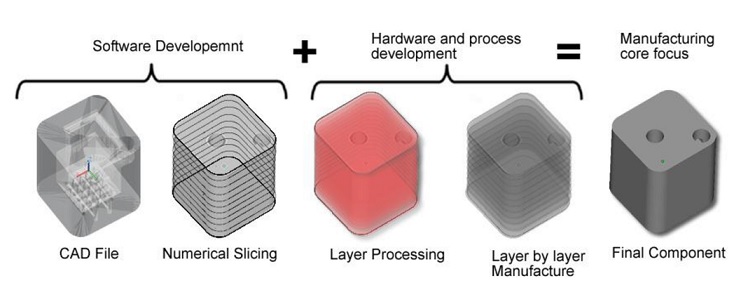

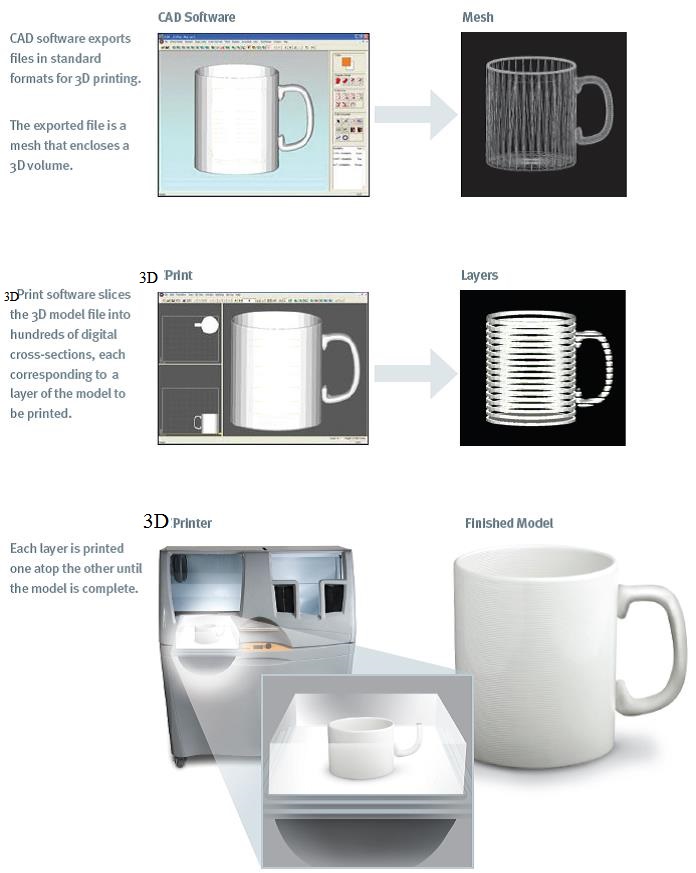

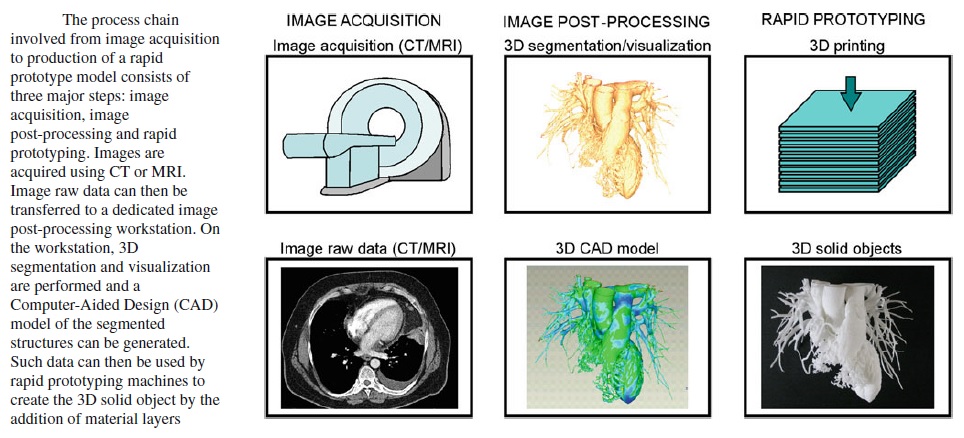

3D printing starts with a digital file derived from computer aided design (CAD) software. Once a design is completed, it must then be exported as a standard tessellation language (STL) file, meaning the file is translated into triangulated surfaces and vertices. The STL file then has to be sliced into hundreds – sometimes thousands – of 2-D layers. A 3D printer then reads the 2-D layers as building blocks which it layers one atop the other, thus forming a three dimensional object. All design files, regardless of the 3D printing technology, are sliced into layers before printing. Layer thickness – the size of each individual layer of the sliced design – is determined partly by technology, partly by material, and partly by desired resolution and your project timeline; thicker layers equates to faster builds, thinner layers equate to finer resolution, less visible layer lines and therefore less intensive post-processing work. After a part is sliced, it is oriented for build.

Orientation:

Orientation refers to how and which direction a part is placed on the 3D printing build platform. For example, a part may be oriented at an angle, or lying flat/ standing vertical. Similar to CNC machining, orientation factors into the outcome of surfaces and details on a 3D printed part. Because 3D printing builds one 2-D layer at a time, the individual lines appear as ribbed surfaces on parts. Downward facing surfaces usually reveal more layer lines. Certain build orientations are better for curved or square features while delicate features require special consideration. Technologies with higher instances of warp (or material deformation) must account for large flat surfaces during build orientation. It is critical to consider these factors because how a part is oriented determines where supports are added – or needed – within the build. Supports are a huge factor for 3D printing, and can affect material finish and accuracy of a 3D printed part.

Supports:

Most 3D printing processes require support structures to act as “scaffolding” for features that can’t be built above open air, such as overhangs, undercuts, holes, cavities, etc. Where supports are required largely depends on the material, build process (3D print technology) and build resolution (layer thickness), among other factors. Support structures are usually made using the same or similar material as the final build and are removed after the model cures.

_

_

No matter which approach a 3-D printer uses, the overall printing process is generally the same. In their book “Additive Manufacturing Technologies: Rapid Prototyping to Direct Digital Manufacturing,” Ian Gibson, David W. Rosen and Brent Stucker list the following eight steps in the generic AM process:

- Step 1: CAD — Produce a 3-D model using computer-aided design (CAD) software. The software may provide some hint as to the structural integrity you can expect in the finished product, too, using scientific data about certain materials to create virtual simulations of how the object will behave under certain conditions.

- Step 2: Conversion to STL — Convert the CAD drawing to the STL format. STL, which is an acronym for standard tessellation language, is a file format developed for 3D Systems in 1987 for use by its stereolithography apparatus (SLA) machines. Most 3-D printers can use STL files in addition to some proprietary file types such as ZPR by Z Corporation and ObjDF by Objet Geometries.

- Step 3: Transfer to AM Machine and STL File Manipulation — A user copies the STL file to the computer that controls the 3-D printer. There, the user can designate the size and orientation for printing. This is similar to the way you would set up a 2-D printout to print 2-sided or in landscape versus portrait orientation.

- Step 4: Machine Setup — Each machine has its own requirements for how to prepare for a new print job. This includes refilling the polymers, binders and other consumables the printer will use. It also covers adding a tray to serve as a foundation or adding the material to build temporary water-soluble supports.

- Step 5: Build — Let the machine do its thing; the build process is mostly automatic. Each layer is usually about 0.1 mm thick, though it can be much thinner or thicker. Depending on the object’s size, the machine and the materials used, this process could take hours or even days to complete. Be sure to check on the machine periodically to make sure there are no errors.

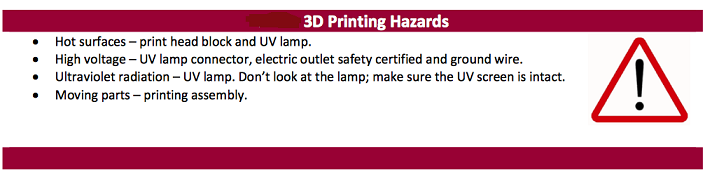

- Step 6: Removal — Remove the printed object (or multiple objects in some cases) from the machine. Be sure to take any safety precautions to avoid injury such as wearing gloves to protect yourself from hot surfaces or toxic chemicals.

- Step 7: Post-processing — Many 3-D printers will require some amount of post-processing for the printed object. This could include brushing off any remaining powder or bathing the printed object to remove water-soluble supports. The new print may be weak during this step since some materials require time to cure, so caution might be necessary to ensure that it doesn’t break or fall apart.

- Step 8: Application — Make use of the newly printed object or objects.

_

The digital model is typically created in either CAD (computer aided design) which is generally used when mechanical parts and precision are needed or a polygon modeler which are typically used for animation and game assets. Examples of CAD programs are AutoCAD, SolidWorks and 123D Design. Some popular polygon modelers are Maya, 3ds Max and Blender. The model can even be created by scanning a real object, but regardless of how it’s done; the model is eventually exported as an STL (standard tessellation language) file which simply describes the surface geometry of the model in triangles. The STL should always be processed through a mesh repair program such as netfabb since during construction it is very easy to create a mesh that won’t print properly due to defects in the mesh. Once repaired, the STL file has to be ‘sliced’ into the layers that will be drawn by the printer, one at a time, layer-by-layer on top of each other until the object is completed. The STL is brought into a slicing program where you specify how thick each layer should be (resolution, typically in microns), what type of material is to be used, how solid the finished piece should be (solid, hollow, or in-between), how fast it should print and whether support material is to be used. This all varies based on type and brand of the printer and what software is being used. Really big or complicated models can take a long time to slice, particularly on home printers. The slices are turned into g-code; a machine language used for manufacturing on both CNC machines and 3D printers and describes the tool path for printing.

_______

Now I will go into details of 3D printing process:

_

General Principles:

- Modelling: It takes virtual blueprints from modelling software and “slices” them into digital cross-sections for the machine to successively use as a guideline for printing.

- Printing: To perform a print, the machine reads the design from an .stl file and lays down successive layers of liquid, powder, paper or sheet material to build the model from a series of cross section.

- Finishing

_

3D model:

It all starts with making a virtual design of the object you want to create. A 3D model is the virtual design that a 3D printer needs to print an object. In 3D computer graphics, 3D modelling (or three-dimensional modelling) is the process of developing a mathematical representation of any three-dimensional surface of an object (either inanimate or living) via specialized software. The product is called a 3D model. Creating three-dimensional models using computer software can be referred to using many terms, but they all generally interchangeable: 3D modelling, 3D drawing, 3D design, 3D computer aided design (3D CAD). You can get your very own 3D file by downloading it, 3D scanning an object, by a plain digital camera and photogrammetry software, hiring a 3D designer, or designing it with 3D modelling software. 3D printed models created with CAD result in reduced errors and can be corrected before printing, allowing verification in the design of the object before it is printed. When you have a 3D model, the next step is to prepare it in order to make it 3D printable.

_

Computer-Aided Design (CAD) Software:

Producing a digital model is the first step in the additive manufacturing process. The most common method for producing a digital model is computer aided design (CAD). There are a large range of free and professional CAD programs that are compatible with additive manufacture. Commercial software such as CAD software AutoCAD and Pro Engineer, software packages Rhino, Maya, and SolidWorks are all pretty good for designing 3D models. If you’re a beginner in 3D design you can try some of 3D modelling software which can be downloaded for free; for example Google SketchUp, 3Dtin, Blender, OpenSCAD and Tinkercad. When designing a part to be 3D printed the following points need to be kept in mind:

- The part needs to be a solid, that is, not just a surface; it needs to have a real volume.

- Creating very small, or delicate features may not be printed properly, this depends greatly on the type of 3D printer that is going to be used.

- Parts with overhanging features will need supports to be printed properly. This should be taken into account since after the model needs to be cleaned by removing the supports. This may not be an issue unless the part is very delicate, since it might break.

- Be sure to calibrate the 3D printer before using it, it is essential to ensure that the part sticks properly to the build plate. If it does not, at some point the part may come loose and ruin the entire print job.

- Some thought should be given to the orientation of the part, since some printers are more precise on the X and Y axes, then the Z axis.

_

3D Scanners:

3D scanning is a process of collecting digital data on the shape and appearance of a real object, creating a digital model based on it. All the digital fabrication, CNC machine tools and CAD software programmes are ways to turn bits into atoms. But how about the reverse: turning atoms into bits? It’s hard to draw 3D objects from scratch on a screen unless you are proficient in AutoCAD or Solidworks; much easier is to just start with something similar that already exists, and then modify it. This process is called ‘reality capture’. The idea is that you can take any object and scan it, creating a ‘point cloud’ of dots that define its surface. Then other software turns that cloud of points into a mesh of polygons, just like the ‘wireframes’ that make up the characters in computer-animated films, which can be manipulated and modified on screen. You can buy a commercial 3D scanner that can do this with lasers that trace over an object and cameras that capture the positions of points on its surface, but there are cheaper ways, too. Autodesk offers a free online service called 123D Catch that allows you to upload regular photographs of an object (taken from all angles), and cloud-based software will turn it into a 3D object that you can then modify and print on a 3D printer.

_

Some 3D printers have a built-in scanner and computer, making it a creative powerhouse. You can use the scanner to scan any item and then slice and modify the resulting image with the built-in computer – this printer lets you make a 3D copy without touching your computer or other hardware.

_

3D Printing Pen:

3D Printing pens are recent developments in modelling as a result of advancements in 3D designing technology. The best 3D drawing pen enables users to make drawings in three dimensions which give clear and concise designs, and representations of initial abstract ideas possessed only by the user. The pen has a plastic component that’s heated to a liquid which is used to make drawings as it’s expelled from the nozzle of the pen. They have low power requirements, and their size and weight enable working with a single hand. To those who are passionate about 3D modelling and drawing, these pens offer endless possibilities of making their ideas real. Considering this is a new technology, still in its infancy, very few individuals and organizations understand it let alone use it.

_

Girl uses a 3D pen to model an item

_

Parametric vs. Explicit Modelling:

If you are weighing these options you are already an advanced user, nevertheless it may be good to know that there are two distinct methods for ‘defining’ 3D geometry. The parametric approach is typically used by engineers and architects because the file contains more specific dimensions, relationships, and can include a design history. The explicit approach is typically used by artists and industrial designers because it can be more flexible. Explicit modelling allows changes to be made on the fly and small changes are not necessarily related to any other defined point of the geometry.

________

3D Printing geometry restrictions:

The size and geometric restrictions must be considered when determining whether a model is suitable for 3D printing. These type of considerations apply to a wide range of industries who use CAD in design and are intending to get a design 3D printed from basic component modelling to complex architectural models.

_

Physical size:

The table below identifies the build volume of a range of different printing technologies. It is important to note that as build volume increases more industrial printing technologies are typically used, increasing the overall price of the print.

Build volumes for a range of 3D printing technologies:

| Technology | Maximum build volume |

| Desktop FDM (Ultimaker 2+) | 220 mm x 223 mm x 205 mm |

| SLA (Form 2) | 145 mm x 145 mm x 175 mm |

| SLS (EOS P 396 printer) | 340 mm x 340 mm x 600 mm |

| Industrial FDM (Fortus 900mc) | 914 mm x 610 mm x 914 mm |

_

Element thickness:

Often architects or game designers will produce elements within a design that have an infinitesimal thickness (hair, capes, sails etc.). These features are impossible to 3D print unless they meet a minimum printable feature size. These requirements vary by printing technology (the smallest possible feature size being 0.3mm printed with SLA technology). All elements within a model must comply to these feature restrictions to be able to print successfully.

_

Water-tightness:

Any models that are intended to be used for 3D printing should be completely manifold (water-tight). Every edge on your model should have exactly 2 polygons attached to it and include no holes. Models that are not manifold (watertight) might get misinterpreted by the software that generates the instructions for the 3D printer (slicer software). This might results in the object having inconsistent layers, holes or cause the model to be unprintable. Water-tightness is often linked to the thickness of elements in a model with very thin features usually causing a problem. Non-manifold issues are often not visible at the modelling stage. The simplest method of checking whether a model is water-tight is to upload the model to an analyser program like Netfabb or Meshmixer. These programs detect model features that will cause issues at the 3D printing stage and offer repair options (often without impacting the overall aesthetics of the model).

_

Curved surfaces:

Most CAD modelling programs such as Solidworks and Fusion360 use non-uniform rational basis spline (NURBS) to display surfaces of a model. When exporting your file to .STL for 3D printing it is important that an adequate number of polygons are used to represent a surface to ensure it will print with a smooth appearance. If not, the edges connecting individual polygons (essentially flat planes) will be visible in the final 3D print. When printing in high-detail 3D printing technologies such as SLA, DLP and PolyJet these polygons are often visible. This effect is more prominent with large scaled models (greater than 300 mm^3) where the polygon effect becomes more visible on curved surfaces. The majority of modelling programs export solid models with an adequate number of polygons resulting in the 3D print that is perfect acceptable for most applications. If a higher polygon count is required to improve 3D print surface finish, analyser programs like Netfabb or Meshmixer allow this parameter to be varied.

__

Printing hollow part:

When 3D printing you must consider the structural integrity of the part otherwise it may collapse while being built. So build internal supports that will be used to build upon, adjust the internal dimensions so that there would be a more supportive structure on the interior allowing it to remain hollow and keep the external features of a hollow part to a more buildable position and hope for the best!

_

With all that being said, there is always a general rule of thumb with 3D printing: If you succeed on the first attempt it was either an easy structure or you got lucky. The most important part of any print is the first few layers. If you build a good solid base for your 3D print then it will at least have a chance. If something goes wrong in the first few minutes it’s not going to get better. Cancel the print before you waste more time.

________

File Types used in 3D Printing:

When designing 3D models and 3D printing, you’re likely to encounter a variety of file types. Some file types are related to the design software, some are associated with 3D scanners, and other file types are proprietary to certain brands of printers. With so many different files, keeping track of what files are used for what processes can be confusing. While there are many different file types that can be used in 3D printing and modelling, here’s a list of some common file extensions you’ll see in 3D printing:

OBJ: OBJ is an open file format that represents 3D geometry. It is a common file used in 3D printing because many design software exports to OBJ and most printers accept OBJ as a printable file.

STL: STL files are a standard file type that interfaces between Computer Aided Design (CAD) software and 3D printers. Most CAD software exports to an STL file and most 3D printers accept STL files. .STL format was created to support Chuck Hull’s original printer. It supports a layering process for one extruder. As printers developed, other formats, both open-source and proprietary, were developed.

VRML: VRML (or WRL) files are commonly used when a 3D model has color and you want to transfer that color to the print.

X3G : X3G is the file type that interfaces with the MakerBot 3D printer. MakerWare and ReplicatorG will output an X3G file.

PLY: PLY files are normally scanner- generated models and will have to be imported into some type of design software before sending to a 3D printer to print.

FBX: FBX is a file format owned by Autodesk. It is used to efficiently exchange data between Autodesk programs including 3ds Max, Autodesk and Maya.

3MF: 3D manufacturing format – In 2015, the 3D Manufacturing Format (.3MF) was announced. Developed and supported by the 3MF Consortium, the aim is to standardize 3D print files.

_

STL file:

STL (Stereolithography) is a file format native to the stereolithography CAD software created by 3D Systems. STL has several after-the-fact backronyms such as “Standard Triangle Language” and “Standard Tessellation Language”. This file format is supported by many other software packages; it is widely used for rapid prototyping, 3D printing and computer-aided manufacturing. STL files describe only the surface geometry of a three-dimensional object without any representation of color, texture or other common CAD model attributes. The STL format specifies both ASCII and binary representations. Binary files are more common, since they are more compact. STL file contains data describing the layout of a three-dimensional object. These files are usually generated by a computer-aided design (CAD) program. “.STL” is the file extension of the STL file format. The STL file format is the most commonly used file format for 3D printing. When used in conjunction with a 3D slicer, it allows a computer to communicate with 3D printer hardware.

_

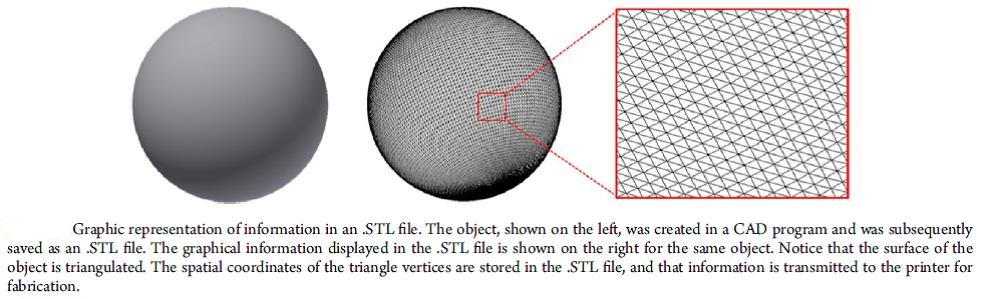

In simple terms, the STL file format uses a series of linked triangles to recreate the surface geometry of a solid model. For a basic model, its surfaces can be represented using a few triangles. For higher resolution models, more triangles are required to replicate the surface of the model. The more triangles that make up a model, the bigger the file size and the more detailed the object. The STL file format can define complex shapes (mathematically speaking, polyhedrons with any polygonal facets). In practice, it is mostly used to describe the layout of triangles in a virtual space. Diving a bit deeper, each triangle facet is described by a perpendicular direction and three points which represent the corners of the triangle. An STL file provides a complete listing of the x, y and z coordinates of these corners and perpendiculars. The STL file format made it possible to transfer three-dimensional CAD models to 3D Systems’ very first commercial 3D printers, the StereoLithography Apparatus. Since this initial release, the technical specifications of the STL file format have remained virtually unchanged.

_

Is every STL file 3D printable?

No.

Only a 3D design that’s specifically made for 3D printing is 3D printable. The STL file is just the container for the data, not a guarantee that something is printable. 3D models suitable for 3D printing need to have a minimum wall thickness and a “watertight” surface geometry to be 3D printable. Even if it’s visible on a computer screen, it’s impossible to print something with a wall thickness of zero. There’s also the consideration of overhanging elements on the model. When downloading an STL file that you haven’t created yourself, it’s worth taking the time to verify that it is indeed 3D printable. This will save you a lot of time and frustration (and wasted filament).

_

While .STL reigns king, the .AMF (Additive Manufacturing Format) and .3MF (3D Manufacturing Format) file formats are jockeying for position.

_

3MF file:

3D Manufacturing Format or 3MF is a file format developed and published by the 3MF Consortium. 3MF is an XML-based data format designed for using additive manufacturing, including information about materials, colors, and other information that cannot be represented in the STL format. As of today, CAD software related companies such as Autodesk, Dassault Systems and Netfabb are part of the 3MF Consortium. Other firms in the 3MF Consortium are Microsoft (for Operating system support), SLM and HP, whilst Shapeways are also included to give insight from a 3D Printing background. Other key players in the 3D printing and additive manufacturing business, such as Materialise, 3D Systems, Siemens PLM Software and Stratasys have recently joined the consortium.

__

AMF(Additive Manufacturing Format) file:

In 2009, the American Society for Testing and Materials tasked ASTM Committee F42 on Additive Manufacturing Technologies to address the need for a replacement to the .STL file. At the time it was dubbed “STL 2.0” and a design subcommittee led the development effort. Their goal was to create a file format analogous to a .PDF file for documents, containing as much information possible to describe an object in the same way. This would provide more data prior to conversion into a format for fabrication and would also allow developers to create OEM software that could pick and choose whatever information was necessary for their 3D printing hardware to operate. The subcommittee developed the .AMF format for technology independence, simplicity, scalability, performance, and both future and backward compatibility. Its first iteration was developed in 2011 and subsequently approved in 2013 in conjunction with the International Standards Organization (ISO). AMF is an XML-based open format that provides complete information through a hierarchy of five main elements: object, material, texture, constellation, and metadata. This provides the basis for information on a model’s shape, composition, color, materials, and geometry. It also introduces the concept of print constellations, allowing information on multiple objects to be positioned and arranged together. This would result in increased packing efficiency or for use with large arrays of identical objects that would be 3D printed on a single build tray. Among .AMF’s additional characteristics: XML-based for easy reading, writing, and processing with as much information as possible to describe an object, its materials, and other manufacturing features. While starting off slow, acclimation to .AMF has grown since its introduction. CAD vendors originally took a “wait and see” approach to the matter, preferring to integrate .AMF according to customer demand. Development has been ongoing since and eventually gained a foothold with larger application such as SOLIDWORKS and Autodesk’s suite of products. Stratasys also signalled its cooperation, foreseeing the potential benefits in .AMF and continue to support it today. 3D printing service providers such as Shapeways and Materialise added .AMF to their lineup of accepted formats while also contributing resources to its development. Due to the myriad of interdependent technology requirements these companies require, .AMF was ready to work with 3D printers on the market today. In addition, conversion and creation tools have been developed to help users migrate older .STL files to .AMF.

| Comparison of STL & AMF – 10cm Sphere (Solid Edge) | ||

| STL Format

(Binary) |

AMF Format

(Curved Triangles) |

|

| PRECISION | 10 micron | 10 micron |

| NO. OF MESH TRIANGLES | 49,500 | 320 |

| FILE SIZE | 2400k | 10k |

______

Printing:

Before printing a 3D model from an STL file, it must first be examined for errors. Most CAD applications produce errors in output STL files: holes, faces normals, self-intersections, noise shells or manifold errors. A step in the STL generation known as “repair” fixes such problems in the original model. Generally STLs that have been produced from a model obtained through 3D scanning often have more of these errors. This is due to how 3D scanning works-as it is often by point to point acquisition, reconstruction will include errors in most cases. Once completed, the STL file needs to be processed by a piece of software called a “slicer,” which converts the model into a series of thin layers and produces a G-code file containing instructions tailored to a specific type of 3D printer. This G-code file can then be printed with 3D printing client software (which loads the G-code, and uses it to instruct the 3D printer during the 3D printing process).

_

G-code:

Lots of 1s and 0s are involved, meaning lots and lots of computer code. Once a 3D model is designed or simply downloaded, the file (these usually have extensions such as 3MF, STL, OBJ, PLY, etc.) must be converted into something called G-code. G-code is a numerical control computer language used mainly for computer aided manufacturing (both subtractive and additive manufacturing). It is a language which tells a machine how to move. Without G-code there would be no way for the computer to communicate where to deposit, cure or sinter a material during the fabrication process. Programs such as Slic3r are required in order to convert 3D model files into G-code. Once the G-code is created it can be sent to the 3D printer, providing a blueprint as to what its next several thousand moves will consist of. These steps all add up to the complete fabrication of a physical object. There are other computer languages out there and perhaps many will eventually gain popularity, but for now G-code is by far the most important. G-code is a numerical control (NC) programming language. It is used in computer-aided manufacturing (CAM) to control automated machine tools (including CNC machines and 3D printers). The slicer program also allows the designer to customise the build parameters including support, layer height, and part orientation. Very simply, G-code tells computerized machine tools – like laser systems – what to do and how to do it. For example, how fast to move, what path to take, etc. Most of the 3D Printer software are written in Python, Java or C++.

M-code:

M-code is for miscellaneous function; it can control auxiliary functions such as coolant but can also perform machine specific functions.

_

Printer resolution:

Printer resolution describes layer thickness and X-Y resolution in dots per inch (dpi) or micrometers (µm). Typical layer thickness is around 100 µm (250 DPI), although some machines can print layers as thin as 16 µm (1,600 DPI).

_

3D printing machines often comprise of many small and intricate parts so correct maintenance and calibration is critical to produce accurate prints. The raw materials used in additive manufacturing often have a limited shelf life and require careful handling. While some processes offer the ability to recycle excess build material, repeated reuse can result in a reduction in material properties if not replaced regularly. Most additive manufacturing machines do not need to be monitored after the print has begun. The machine will follow an automated process and issues generally only arise when the machine runs out of material or there is an error in the software. Construction of a model with contemporary methods can take anywhere from several hours to several days, depending on the method used and the size and complexity of the model. Additive systems can typically reduce this time to a few hours, although it varies widely depending on the type of machine used and the size and number of models being produced simultaneously. Traditional techniques like injection moulding can be less expensive for manufacturing polymer products in high quantities, but additive manufacturing can be faster, more flexible and less expensive when producing relatively small quantities of parts. 3D printers give designers and concept development teams the ability to produce parts and concept models using a desktop size printer. Seemingly paradoxical, more complex objects can be cheaper for 3D printing production than less complex objects.

_

Removal of prints:

For some additive manufacturing technologies removal of the print is as simple as separating the printed part from the build platform. For other more industrial 3D printing methods the removal of a print is a highly technical process involving precise extraction of the print while it is still encased in the build material or attached to the build plate. These methods require complicated removal procedures and highly skilled machine operators along with safety equipment and controlled environments.

_

Post processing and Finishing:

3-D printers eliminate the need for further machining or subtracting processes such as cutting and grinding; the final product is built in three dimensions without waste. Though the printer-produced resolution is sufficient for many applications, printing a slightly oversized version of the desired object in standard resolution and then removing material with a higher-resolution subtractive process can achieve greater precision. Some printable polymers such as ABS, allow the surface finish to be smoothed and improved using chemical vapor processes based on acetone or similar solvents. Some additive manufacturing techniques are capable of using multiple materials in the course of constructing parts. These techniques are able to print in multiple colors and color combinations simultaneously, and would not necessarily require painting. Some printing techniques require internal supports to be built for overhanging features during construction. These supports must be mechanically removed or dissolved upon completion of the print. All of the commercialized metal 3D printers involve cutting the metal component off the metal substrate after deposition. A new process for the GMAW 3D printing allows for substrate surface modifications to remove aluminum or steel. Post processing procedures again vary by printer technology. SLA requires a component to cure under UV before handling, metal parts often need to be stress relieved in an oven while FDM parts can be handled right away. For technologies that utilize support, this is also removed at the post processing stage. Most 3D printing materials are able to be sanded and other post processing techniques including tumbling, high pressure air cleaning, polishing and colouring are implemented to prepare a print for end use.

____

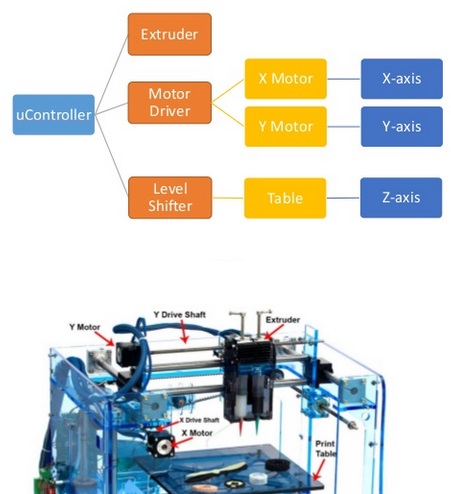

X, Y and Z axis:

3D Printers use a laser or extruder (the material output part of the printer), that move along an X, Y and Z axis to build an object in three dimensions, wherein successive layers of material are laid down in different shapes. 3D printers use a variety of very different types of additive manufacturing technologies, but they all share one core thing in common: they create a three dimensional object by building it layer by successive layer, until the entire object is complete. It’s much like printing in two dimensions on a sheet of paper, but with an added third dimension: UP. The Z-axis. Each of these printed layers is a thinly-sliced, horizontal cross-section of the eventual object. Imagine a multi-layer cake, with the baker laying down each layer one at a time until the entire cake is formed. 3D printing is somewhat similar, but just a bit more precise than 3D baking. In the 2D world, a sheet of printed paper output from a printer was “designed” on the computer in a program such as Microsoft Word. The file – the Word document which contains the instructions that tell the printer what to do. In the 3D world, a 3D printer also needs to have instructions for what to print. It needs a file as well. The file, a Computer Aided Design (CAD) file is created with the use of a 3D modelling program, either from scratch or beginning with a 3D model created by a 3D scanner. Either way, the program creates a file that is sent to the 3D printer. Along the way, software slices the design into hundreds, or more likely thousands, of horizontal layers. These layers will be printed one atop the other until the 3D object is done.

_

Figure of uController of 3D printer:

The picture shows the structure of a typical 3D printer. The print table is the platform where the object for printing has been situated. It provides the basic support for manufacturing objects layer by layer. The extruder is the most important part of a 3D-Printer. As the extruders in the normal paper printers, this extruder is also used to pour ink for printing. The movement of extruder in various dimensions create the 3D print. For printing a 3d object, the extruder has to access X, Y and Z coordinates. For achieving this, many techniques are used according to the printer specification required for various applications. If the 3D-Printer is a desktop printer, the Z axis movement of the extruder can be avoided and that function can be transferred to the print table. This will avoid complexity in 3D printing as well as time consumption. When the STL file is input to the printer, the microcontroller extracts each layer from it and also extracts each line segment from each layer. Then it gives controls to the movement of the extruder at required rate. The X-direction movement of extruder is made possible by the X-motor. When the X motor rotates, the shaft also rotates and the extruder moves in X direction. The Y-direction movement of extruder is made possible by the Y-motor. When the Y motor rotates, the shaft also rotates and the extruder moves in Y direction. The Z direction movement is made by the print table. In the case of desktop printers, the printing ink is usually plastic wire that has been melted by the extruder at the time of printing. While printing, the plastic wire will melt and when it fall down to the printing table. The original MakerBot is one of the simplest 3D printers. It has just four motors: the x, y, and z, along with a fourth motor to drive the ABS plastic filament (or other material) through a heater to melt it and then onto the build platform to make the object. Consider printing larger objects like house using 3D printer. There will not be any X motor or Y motor in that case. An extruder which can pour concrete mix is fixed on the tip of a crane. The crane is programmed for the movement of extruder in X, Y and Z axis. The concept and structure of 3D printer changes according to the type, size, accuracy and material of the object that has to be printed. Generalizing the facts, the extruder need to access all the 3 coordinates in space to print and object. The method used for that doesn’t matters much.

______

______

The basic concepts of additive manufacturing:

- Tolerance

Tolerance shows the ability for parts to fit together, and is important when creating something like joints. Ensure there is enough space for tolerancing when creating moving parts. A great example of tolerance in practice is 3D printed ball joints, where there are no support structures in place between the socket and the ball. The ball joint comes fresh off the print bed, already articulated and fully rotating.

- Maximum Size

If your model falls outside the printable area of the 3D printer, consider breaking it down into smaller pieces that can be printed separately, or scale the size of the model to fit.

- Colors

Color is critical in the look and feel of a 3D printed object; it has a significant impact on bringing out finer details, and complements the final design. When evaluating the range of colors for a 3D print job, or demonstrating them to others, you could browse through a color swatch book. Or you could lug several spools of filament around. Or you could save yourself the trouble just by printing basic blocks of color with the shade labelled on it. When printing them off, of course, remember to align the correct color filament to the label.

- Infill

The principle of infill is that, for those interior parts of a model that will never be seen once the print job is completed, the infill doesn’t necessarily need to be 100% solid. Instead, it can be a basic honeycomb or diamond grid that provides structural integrity. The benefit of this principle is two-fold. First, it saves time when printing an object. Secondly, it reduces the amount of filament being used.

- Over Hang

As a general rule, you shouldn’t allow your model to have too many over hangs without anything under them. Anything at less than a 45 degree angle will require supports. Anything more than 45 degrees doesn’t need support.

- Bridging

Bridging is self-explanatory. You have to print “bridges” across empty space between two solid shapes. The larger the space the bridge has to traverse, the more likely it will dip downwards as the fused filament cools. One way to avoid the pitfalls of bridging is to consider the orientation of the model when it’s being printed. For example, let’s consider a small rectangular table for a doll’s house. Printing it upright — as you would normally visualize it — will cause bridging problems when the printer begins fabricating the surface of the table. But printing it upside down with legs in the air shouldn’t cause any problems.

- Supports

Related to the previous concept, another remedy for bridging is to include removable supports (or rafts) in your print job. These will not as detailed as the main body of the object, and are easily snapped off after the print has finished.

- XYZ axis

The separate axes — X, Y and Z — are fundamental to 3D modelling. Coordinating the three together (via the instructions contained in an STL file) is how a 3D printer plots a point in space when fabricating a physical object. This model can be attached to the 3D printer for handy reference, or perhaps propped up alongside your computer monitor when working with a CAD program.

- Polygons

The resolution of the digital model is a separate consideration from physical print settings like layer height. This is specifically about the number of polygons used to form a shape. The low poly mesh model is a simple design comprised of significantly fewer polygons than the high poly mesh model. The results are obvious, where the surface of the high poly model is smoother and more detailed. The efficiencies of opting for a low-poly model are gained at the design stage, in file-size, and sometimes (but not necessarily always) at the printing stage. Low poly models are especially popular with the 3D model community, allowing designers to render recognizable objects like Pokemon and Yoda in an artistic way using a elegant arrangement of polygons.

- 3D Printers really need to be calibrated.

Basically, you need to make sure that when your Printer’s Head is at X0 Y0 Z0 that you can just barely fit a piece of paper between your extruder nozzle and bed.

_____

Mistakes to avoid when designing 3D Model for 3D Printing:

We all use different software, print in different materials, and not only use different printers but also different printing technologies. So it can sometimes seem difficult to design a perfect 3D model for 3D printing. That’s why we must avoid following mistakes when turning a 3D model into 3D print.

- Ignoring Material Guidelines:

Each and every printing material is different. Materials can be brittle or strong, flexible or solid, smooth or rough, heavy or light, and so on. This also means that an object should ideally be designed for a specific material. For example, if you know that you want to print your 3D model in Ceramics, there will be specific material-related design recommendations that you need to take into account such as supporting overhanging parts, strengthening elements that are sticking out, rounding off corners, etc. The choice of your printing material simply pre-determines some of the basic design guidelines that you need to stick to.

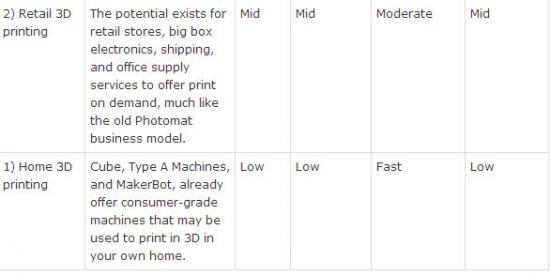

- Ignoring Printing Technology: